E-Catalog > CHANDOX CHUCK > CHANDOX CHUCK

Product Detail :

Super Precision Air Chucks

Product Search

FR

Forming Rings (for soft jaws of super precision air chucks)

TK,TK-T

2、3-Jaw Super Precision Air Chucks

This product reaches the repeatability of "μ degree"

1.Pre-machined tapped holes and lubrication path:There are tapped holes for fixing jigs, thus, additional screw machining is not necessary, and pre-machined lubrication path can connect to auto-lubrication unit to lubricate the chuck automatically.

2.Built-in Cylinder:Connect cylinder directly to the chuck for stable gripping.

3.Precise soft jaw positioning:It’s easy to remount soft jaw to the correct position with dowel pins on it.

4.High gripping precision brings better quality and efficiency:Good coaxiality and repeatability of gripping are able to achieve the accuracy of “μ degree machining processes can be simplified or shortened to make high precision machining with high efficiency come ture.

1.Pre-machined tapped holes and lubrication path:There are tapped holes for fixing jigs, thus, additional screw machining is not necessary, and pre-machined lubrication path can connect to auto-lubrication unit to lubricate the chuck automatically.

2.Built-in Cylinder:Connect cylinder directly to the chuck for stable gripping.

3.Precise soft jaw positioning:It’s easy to remount soft jaw to the correct position with dowel pins on it.

4.High gripping precision brings better quality and efficiency:Good coaxiality and repeatability of gripping are able to achieve the accuracy of “μ degree machining processes can be simplified or shortened to make high precision machining with high efficiency come ture.

SPECIFICATIONS

UNIT/mm

| Inquiry | MODEL / SPEC | A | B | C | D | E | D1 | d (H7) | D2 | H | h | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TK-04 | 20.75 | 12.7 | 12.7 | 101.6 | 30 | 82.55 | 18 | 25 | 70.3 | 3.2 | 16 | |

| TK-06 | 39.75 | 12.7 | 12.7 | 152.4 | 40 | 124.97 | 26 | 34.5 | 70.3 | 3.2 | 22 | |

| TK-08 | 65.75 | 25.4 | -- | 203.2 | 45 | 167.64 | 50 | 50 | 99.5 | 7.0 | 25 | |

| TK-04T | 20.75 | 12.7 | 12.7 | 101.6 | 30 | 82.55 | 18 | 25 | 70.3 | 3.2 | 16 | |

| TK-06T | 39.75 | 12.7 | 12.7 | 152.4 | 40 | 124.97 | 26 | 34.5 | 70.3 | 3.2 | 22 | |

| TK-08T | 65.75 | 25.4 | -- | 203.2 | 45 | 167.64 | 50 | 50 | 99.5 | 7.0 | 25 |

| MODEL / SPEC | M1 | M2 | M3 | T1 | T2 | T3 | R1 | R2 | R3 |

|---|---|---|---|---|---|---|---|---|---|

| TK-04 | 6-M5×0.8P (PCDø88.9) | 6-M5×0.8P | 9-ø3.18 | 3-M5×0.8P (PCDø88.9) | -- | -- | 30° | -- | -- |

| TK-06 | 6-M6×1P (PCDø135.89) | 12-M5×0.8P | 9-Ø3.18 | 3-M6×1P (PCDø135.89) | 3-M6×1P (PCDø110) | 3-M6×1P (PCDø135.89) | 30° | 30° | 75° |

| TK-08 | 6-M10×1.5P (PCDø182.88) | 6-M10×1.5P | 6-ø6.36 | 3-M8×1.25P (PCDø182.88) | 3-M8×1.25P (PCDø150) | 3-M8×1.25P (PCDø100) | 30° | 30° | 30° |

| TK-04T | 6-M5×0.8P (PCDø88.9) | 4-M5×0.8P | 6-ø3.18 | 2-M5×0.8P (PCDø70) | -- | -- | -- | -- | -- |

| TK-06T | 6-M6×1P (PCDø135.89) | 8-M5×0.8P | 6-ø3.18 | 2-M6×1P (PCDø110) | -- | -- | -- | -- | -- |

| TK-08T | 6-M10×1.5P (PCDø182.88) | 4-M10×1.5P | 4-ø6.36 | 2-M8×1.25P (PCDø150) | -- | -- | -- | -- | -- |

| MODEL / SPEC | Jaw Stroke [Diameter] (mm) | Gripping Force At Air Pressure 7kgf/cm2(0.7MPa) kgf(kN) | Max.Speed r.p.m(min-1) | Weight (kg) |

|---|---|---|---|---|

| TK-04 | 3 | 800(7.8) | 4500 | 4.4 |

| TK-06 | 3 | 1200(11.7) | 4200 | 9.8 |

| TK-08 | 3 | 1800(17.6) | 2500 | 26.3 |

| TK-04T | 3 | 800(7.8) | 3500 | 4.2 |

| TK-06T | 3 | 1200(11.7) | 3500 | 9.5 |

| TK-08T | 3 | 1800(17.6) | 2000 | 25.1 |

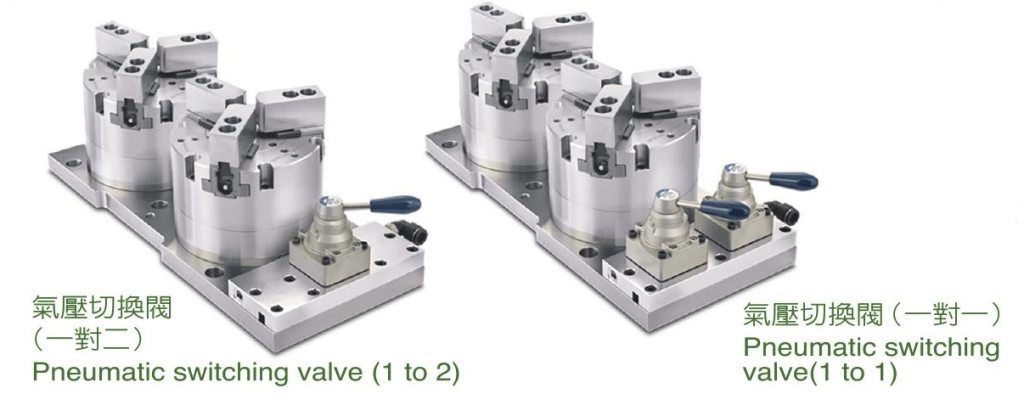

OPERATION EXAMPLE

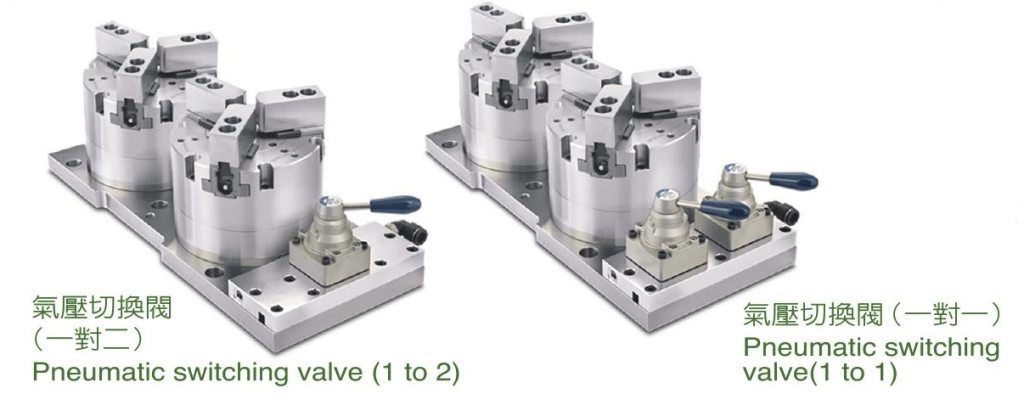

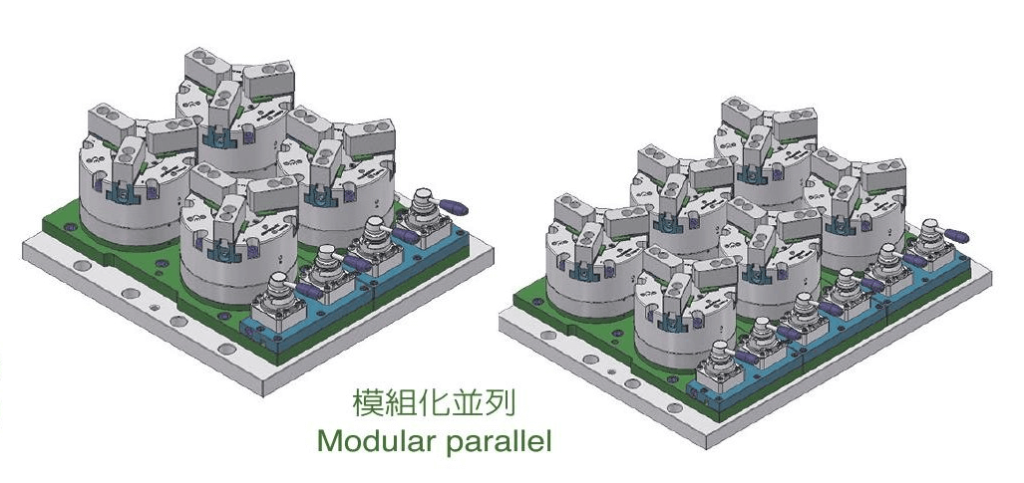

MFR,MFR-M

Air Chuck Fixture(DOUBLE PISTON)

Air Chuck Fixture Special Features:

1.Front-lock design, easy installation & save space.。

2.Available on multi-plate for mass production.。

3.Rust-proof for the pneumatic cylinder.

4.Dusts-proof & water-proof design to maintain its accuracy and lead to longer service life.

5.Twin-pistons to increase the clamping force for heavy-duty cutting.

1.Front-lock design, easy installation & save space.。

2.Available on multi-plate for mass production.。

3.Rust-proof for the pneumatic cylinder.

4.Dusts-proof & water-proof design to maintain its accuracy and lead to longer service life.

5.Twin-pistons to increase the clamping force for heavy-duty cutting.

SPECIFICATIONS

UNIT/mm

| Inquiry | MODEL / SPEC | A | B | C | D | E | F | G | H | I | J | K | R | R1 | R2 | R3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MFR-04 | 125 | 105 | 40 | 11.5 | 131.7 | 26.7 | 14 | 49.5 | 10 | 23 | -- | -- | -- | -- | -- | |

| MFR-06 | 172 | 118 | 40 | 11.5 | 158.4 | 40.4 | 20 | 73 | 12 | 31 | -- | -- | -- | -- | -- | |

| MFR-08 | 210 | 145 | 40 | 14 | 187.4 | 42.4 | 25 | 95 | 14 | 35 | -- | -- | -- | -- | -- | |

| MFR-04-M | 167 | 125 | 15 | 108.5 | 135.2 | 26.7 | 14 | 49.5 | 10 | 23 | 13 | 47 | -- | -- | -- | |

| MFR-06-M | 224 | 172 | 15 | 121.5 | 161.9 | 40.4 | 20 | 73 | 12 | 31 | 18 | 47 | 8.5° | 6.5° | 23.5° | |

| MFR-08-M | 265 | 210 | 20 | 151 | 193.4 | 42.4 | 25 | 95 | 14 | 35 | 18 | 47 | 9.5° | 5.5° | 24.5° |

| MODEL / SPEC | L | M | N | P | Q | U |

|---|---|---|---|---|---|---|

| MFR-04 | 3-M8×1.25P (PCDø110) | -- | -- | -- | -- | -- |

| MFR-06 | 6-M10×1.5P (PCDø155) | -- | -- | 3-M8×1.25P (PCDø110) | 3-M8×1.25P (PCDø148) | -- |

| MFR-08 | 6-M12×1.5P (PCDø185) | -- | -- | 3-M10×1.5P (PCDø136) | 3-M10×1.5P (PCDø186) | -- |

| MFR-04-M | ø9 (PCDø145) | 2-PT1/8" | M8×1.25P (PCDø145) | -- | 64 | -- |

| MFR-06-M | ø11 (PCDø202) | 2-PT1/4" | M10×1.5P (PCDø202) | 3-M8×1.25P (PCDø110) | 80 | 3-M8×1.25P (PCDø148) |

| MFR-08-M | ø11 (PCDø243) | 2-PT1/4" | M10×1.5P (PCDø243) | 3-M10×1.5P (PCDø136) | 80 | 3-M10×1.5P (PCDø186) |

| MODEL / SPEC | Piston Area (cm2) | Plunger Stroke (mm) | Jaw Stroke [Diameter] (mm) | Gripping Range | Gripping Force At Air Pressure 7kgf/cm2(0.7MPa) kgf(kN) |

|---|---|---|---|---|---|

| MFR-04 | 133 | 9 | 3.8 | ø16~ø125 | 2980(29.2) |

| MFR-06 | 270 | 10 | 5.3 | ø24~ø172 | 5280(51.7) |

| MFR-08 | 380 | 16 | 7.4 | ø25~ø210 | 7800(76.4) |

| MFR-04-M | 133 | 9 | 3.8 | ø16~ø125 | 2980(29.2) |

| MFR-06-M | 270 | 10 | 5.3 | ø24~ø172 | 5280(51.7) |

| MFR-08-M | 380 | 16 | 7.4 | ø25~ø210 | 7800(76.4) |

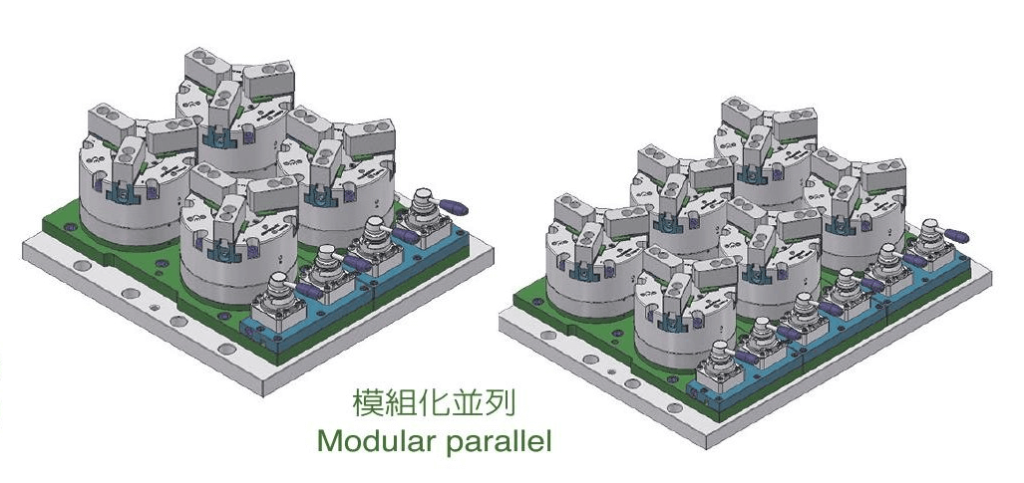

OPERATION EXAMPLE

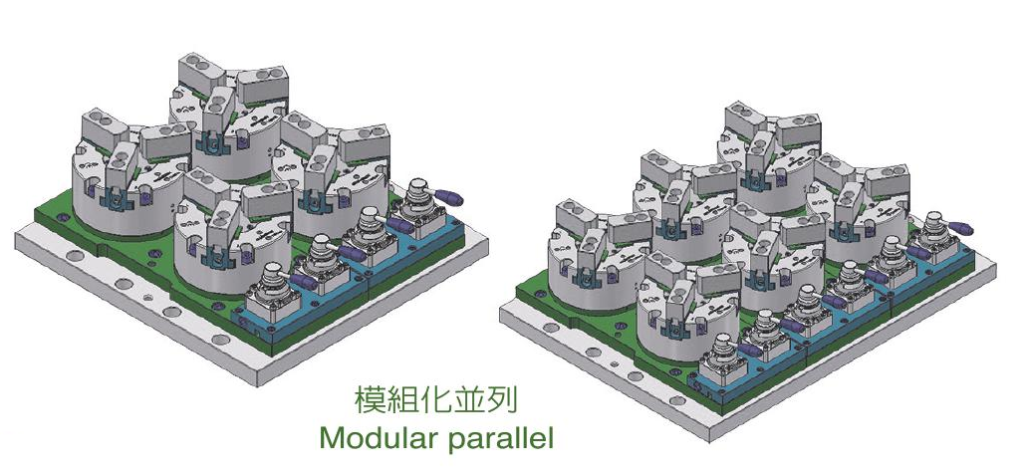

MD,MD-M

Air Chuck Fixture(SINGLE PISTON)

Air Chuck Fixture Special Features

1.Front-lock design, easy installation & save space.

2.Available on multi-plate for mass production.

3.Rust-proof for the pneumatic cylinder.

4.Dusts-proof & water-proof design to maintain its accuracy and lead to longer service life.

1.Front-lock design, easy installation & save space.

2.Available on multi-plate for mass production.

3.Rust-proof for the pneumatic cylinder.

4.Dusts-proof & water-proof design to maintain its accuracy and lead to longer service life.

SPECIFICATIONS

UNIT/mm

| Inquiry | MODEL / SPEC | A | B | C | D | E | F | G | H | I | J | K | R | R1 | R2 | R3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MD-04 | 125 | 78.5 | 40 | 11.5 | 105.2 | 26.7 | 14 | 49.5 | 10 | 23 | -- | -- | -- | -- | -- | |

| MD-06 | 172 | 90 | 40 | 11.5 | 130.4 | 40.4 | 20 | 73 | 12 | 31 | -- | -- | -- | -- | -- | |

| MD-08 | 210 | 108.5 | 40 | 14 | 150.9 | 42.4 | 25 | 95 | 14 | 35 | -- | -- | -- | -- | -- | |

| MD-04-M | 167 | 125 | 15 | 82 | 108.7 | 26.7 | 14 | 49.5 | 10 | 23 | 13 | 47 | -- | -- | -- | |

| MD-06-M | 224 | 172 | 15 | 93.5 | 133.9 | 40.4 | 20 | 73 | 12 | 31 | 18 | 47 | 8.5° | 6.5° | 23.5° | |

| MD-08-M | 265 | 210 | 20 | 114.5 | 156.9 | 42.4 | 25 | 95 | 14 | 35 | 18 | 47 | 9.5° | 5.5° | 24.5° |

| MODEL / SPEC | L | M | N | P | Q | U |

|---|---|---|---|---|---|---|

| MD-04 | 3-M8×1.25P (PCDø110) | -- | -- | -- | -- | -- |

| MD-06 | 6-M10×1.5P (PCDø155) | -- | -- | 3-M8×1.25P (PCDø110) | 3-M8×1.25P (PCDø148) | -- |

| MD-08 | 6-M12×1.75P (PCDø185) | -- | -- | 3-M10×1.5P (PCDø136) | 3-M10×1.5P (PCDø186) | -- |

| MD-04-M | ø9 (PCDø145) | 2-PT1/8" | M8×1.25P (PCDø145) | -- | 64 | -- |

| MD-06-M | ø11 (PCDø202) | 2-PT1/4" | M10×1.5P (PCDø202) | 3-M8×1.25P (PCDø110) | 80 | 3-M8×1.25P (PCDø148) |

| MD-08-M | ø11 (PCDø243) | 2-PT1/4" | M10×1.5P (PCDø243) | 3-M10×1.5P (PCDø136) | 80 | 3-M10×1.5P (PCDø186) |

| MODEL / SPEC | Piston Area (cm2) | Plunger Stroke (mm) | Jaw Stroke [Diameter] (mm) | Gripping Range | Gripping Force At Air Pressure 7kgf/cm2(0.7MPa) kgf(kN) |

|---|---|---|---|---|---|

| MD-04 | 67 | 10 | 3.5 | ø16~ø125 | 1800(17.6) |

| MD-06 | 136 | 12 | 4.2 | ø24~ø172 | 3700(36.2) |

| MD-08 | 191 | 18 | 6.3 | ø25~ø210 | 5150(50.5) |

| MD-04-M | 67 | 10 | 3.5 | ø16~ø125 | 1800(17.4) |

| MD-06-M | 136 | 12 | 4.2 | ø24~ø172 | 3700(36.2) |

| MD-08-M | 191 | 18 | 6.3 | ø25~ø210 | 5150(50.5) |

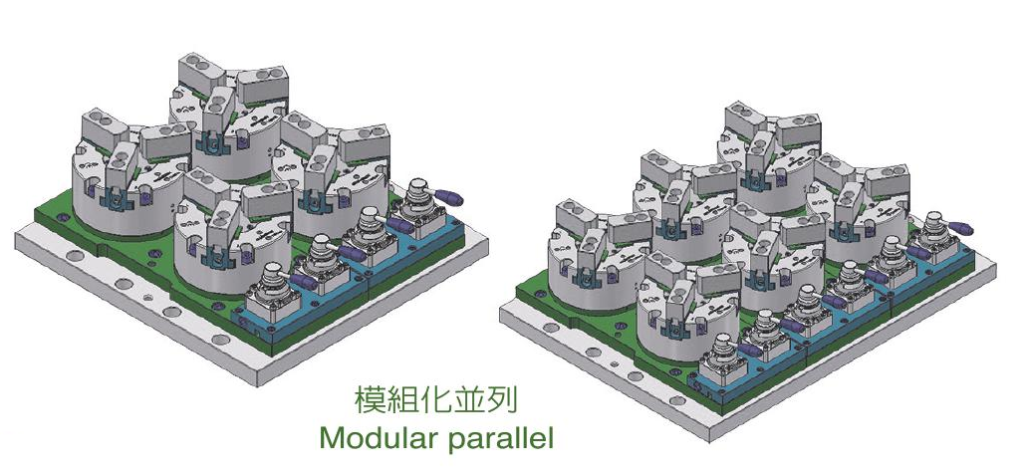

OPERATION EXAMPLE

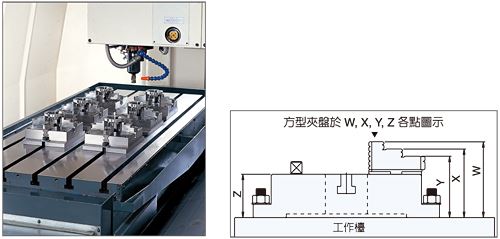

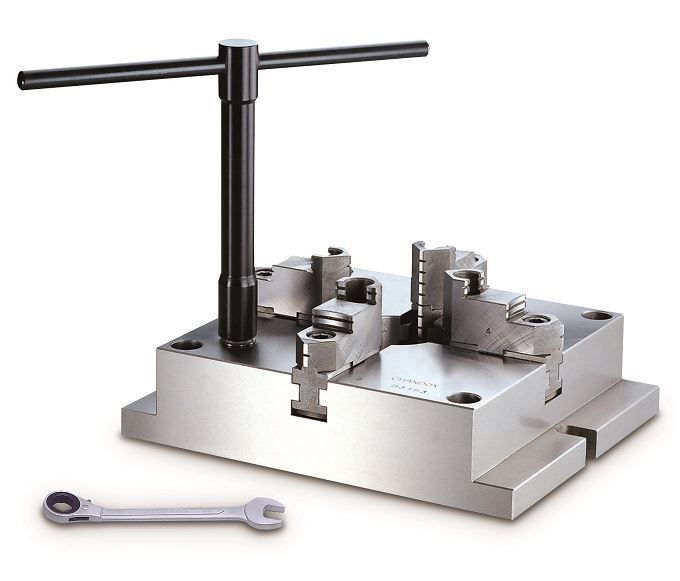

MC

Super Thin Square Chucks

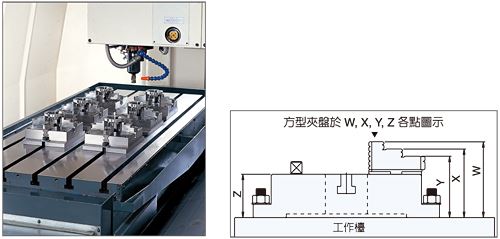

1.MC均為定寸研磨方式:任何相同規格之方型夾盤W, X , Y , Z各點之高度公差為0.05mm以內。

2.MC規格均可替換生爪,作不規則形狀之加工,以替換中心機大量治具,更經濟、方便。

3.硬爪重複夾持之精度公差為0.02mm以內。

4.側邊平行校正後,硬爪夾持之平行公差為0.05mm以內。

2.MC規格均可替換生爪,作不規則形狀之加工,以替換中心機大量治具,更經濟、方便。

3.硬爪重複夾持之精度公差為0.02mm以內。

4.側邊平行校正後,硬爪夾持之平行公差為0.05mm以內。

SPECIFICATIONS

UNIT/mm

| Inquiry | MODEL / SPEC | A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MC-06 | 215 | 57 | 18 | 130 | 40 | 5.5 | 4-M10×1.5P | 68 | 26 | 39 | 14 | 144 | 165 | 144 | 165 | 66 | 18 | |

| MC-08 | 250 | 65 | 20 | 160 | 55 | 6 | 4-M12×1.75P | 82 | 28 | 43 | 17 | 174 | 200 | 174 | 200 | 83 | 18 | |

| MC-10 | 310 | 72 | 22 | 200 | 70 | 6 | 4-M14×2P | 93 | 32 | 50 | 21 | 218 | 250 | 218 | 250 | 104 | 18 | |

| MC-12 | 380 | 85 | 25 | 260 | 100 | 7 | 4-M16×2P | 118 | 40 | 56 | 23 | 274 | 310 | 274 | 310 | 135 | 22 |

| MODEL / SPEC | Max.Gripping Diameter O.D.Clamping | Max.Gripping Diameter I.D.Clamping | Weight (kg) |

|---|---|---|---|

| MC-06 | ø4-ø128 | ø55-ø128 | 11.4 |

| MC-08 | ø5-ø162 | ø62-ø162 | 18.6 |

| MC-10 | ø6-ø200 | ø72-ø200 | 31.6 |

| MC-12 | ø10-ø265 | ø90-ø265 | 56.6 |

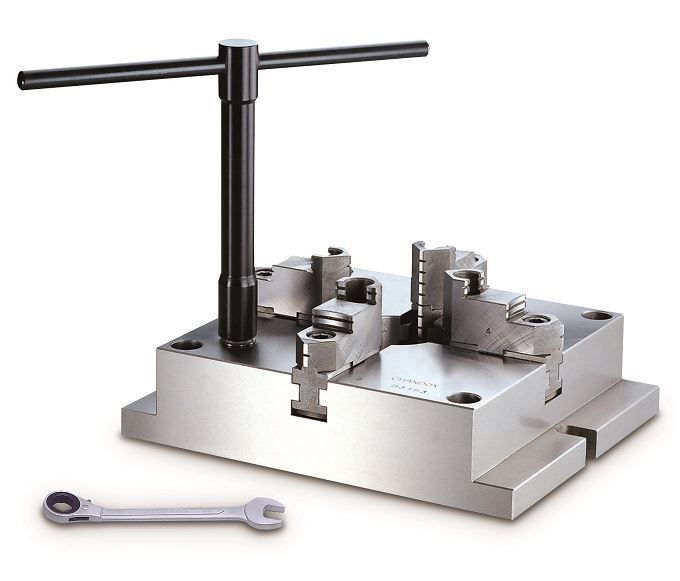

OPERATION EXAMPLE

NBK

Powerful Type Super Thin Chucks

1.The handle with an angle of 30 degrees is much convenient for operations.。

2.The “super thin thickness” design of chucks increase the “allowable distance” of machining operations.

3.Chuck flange makes loading and unloading Operations simpler and more convenient.

4.Hard jaws and soft jaws can be used alternatively.

2.The “super thin thickness” design of chucks increase the “allowable distance” of machining operations.

3.Chuck flange makes loading and unloading Operations simpler and more convenient.

4.Hard jaws and soft jaws can be used alternatively.

SPECIFICATIONS

UNIT/mm

| Inquiry | MODEL / SPEC | A1 | A2 | B1 | B2 | C | D | E | F | G | H | J | K | L | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NBK-06 | 220 | 170 | 58 | 18 | 130 | 147 | 45 | 6 | 3-M10×1.5P | 68 | 26 | 40 | 10 | 13 | |

| NBK-08 | 270 | 210 | 65 | 20 | 155 | 172 | 60 | 6 | 3-M10×1.5P | 82 | 28 | 43 | 11 | 13 | |

| NBK-10 | 315 | 255 | 73 | 20 | 190 | 210 | 80 | 6 | 3-M12×1.75P | 93 | 32 | 52 | 12 | 16 | |

| NBK-12 | 370 | 305 | 80 | 22 | 250 | 285 | 105 | 5 | 3-M12×1.75P | 118 | 40 | 59 | 14 | 18 | |

| NBK-16 | 470 | 405 | 105 | 24 | 345 | 375 | 160 | 7 | 6-M14×2P | 150 | 50 | 75 | 15 | 18 | |

| NBK-20 | 570 | 500 | 121 | 29 | 420 | 458 | 220 | 7 | 6-M16×2P | 140 | 55 | 84 | 19 | 18 |

| MODEL / SPEC | Max.Gripping Diameter O.D.Clamping | Max.Gripping Diameter I.D.Clamping | Weight (kg) |

|---|---|---|---|

| NBK-06 | ø8-ø160 | ø48-ø150 | 10.6 |

| NBK-08 | ø11-ø200 | ø62-ø190 | 18.1 |

| NBK-10 | øOther Product In Group "CHANDOX CHUCK (4)" |