Please select a category.

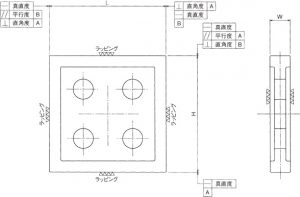

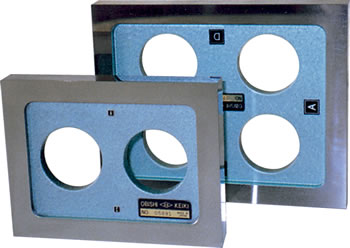

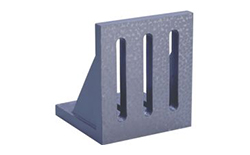

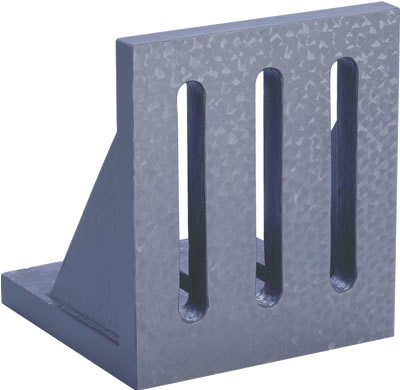

- The base and upright surfaces accuracy is ensured.

- The base and upright surfaces are scrape finished.

- On the base and upright surfaces, slotted holes are provided for fixation of work pieces.

- It can be used as a machining jig if installed on machining centers.

- There is a support on the inner part for works longer than 200mm.

*We also manufacture similar products with special measurement.

| Code No. |

Nominal Measurement |

Measurement

(L×W×H×tmm) |

No of Slotted Holes

(pcs) |

Parallelism

(μm) |

Mass

(kg) |

|---|

| RA101 |

100 |

100×75×75×16 |

2 |

7 |

1.2 |

|---|

| RA102 |

125 |

125×100×100×16 |

3 |

8 |

2.1 |

|---|

| RA103 |

150 |

150×125×125×18 |

9 |

3.6 |

|---|

| RA104 |

175 |

175×150×150×19 |

10 |

5.6 |

|---|

| RA105 |

200 |

200×175×175×20 |

9.2 |

|---|

| RA106 |

250 |

250×200×200×22 |

17.0 |

|---|

| RA107 |

300 |

300×250×250×25 |

24.0 |

|---|

| RA108 |

350 |

350×300×300×25 |

4 |

38.0 |

|---|

| RA109 |

400 |

400×350×350×35 |

70.0 |

|---|

| RA110 |

450 |

450×400×400×37 |

5 |

15 |

87.0 |

|---|

| RA111 |

500 |

500×400×400×45 |

107.0 |

|---|

| RA112 |

600 |

600×450×450×45 |

20 |

160.0 |

|---|

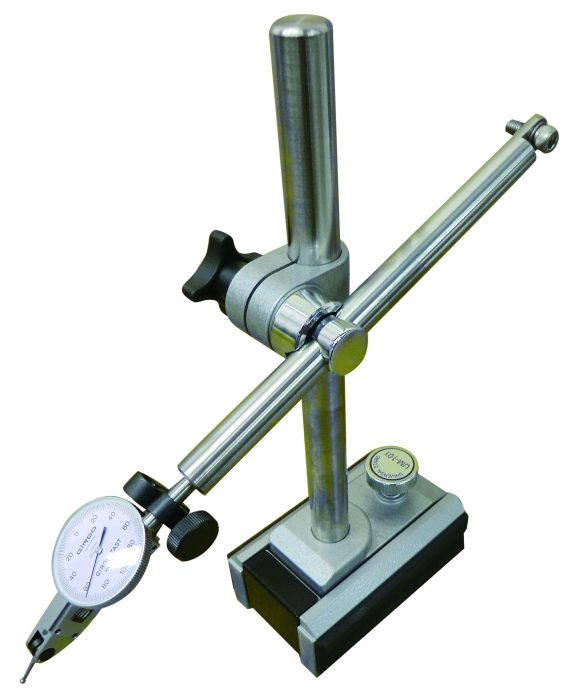

- Stand special for Lever type Dial Gauge

- This Dial Gauge stand can be fine tuned up to the range of 25°. Lever type dial gauge zero setting can be performed quickly.

- The Base was designed putting into consideration operability and stability.

*Dial Gauge is not included.

| Code No. |

Model |

Base Measurement

(L×W×Hmm) |

Main Pole Lenght |

Micro Motion Angle |

Mass

(kg) |

|---|

| MN102 |

MN-102 |

118×80×40 |

347 |

25° |

4.0 |

|---|

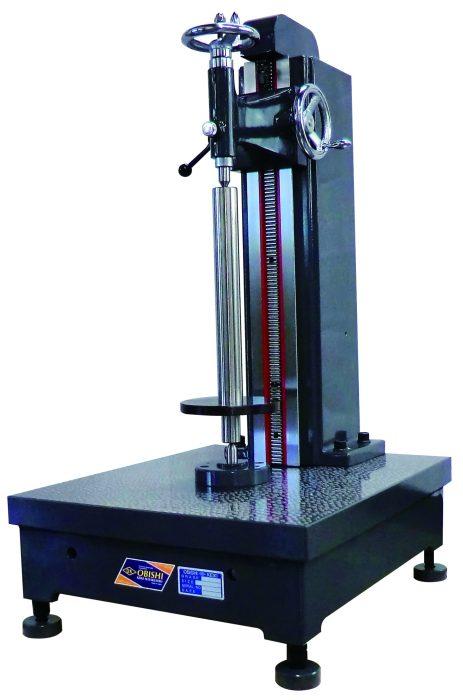

- Zero set can be done easily using a micro motion knob.

- The main pole and arm are chrome plated and do not rust.

- The Base surface and rising edge (1 surface) are hardened and after that polished.

- A nonconducting plate is installed on the side surface

- A Dial Gauge or Lever type Dial Gauge can be attached.

*Dial Gauge is not included.

| Code No. |

Model |

Base Measurement

(L×W×tmm) |

Main Pole Lenght

(φ×Lmm) |

Arm Measurement

(φ×Lmm) |

Mass

(kg) |

|---|

| ME101 |

UM101 |

120×80×54 |

20×245 |

14×215 |

4.5 |

|---|

- For measuring large rolls.

- It is lightweight because light alloy metal is used as the material. (However, the frame is made of Cast Iron)

- 4 pcs of job run roller have bearings in them and they are precision grinded.

- Movement on the roll is slow and smooth.

- A special interval graduation is inprinted on the arm. By matching a bracket onto the work measurement figures, it is possible to easily set a Dial Gauge on the roll center of the work.

*A 0.01mm graduation dial gauge is supplied with the product.

*The storage box is designed in such a way that the main body will have to be disassembled before putting it into the box.

| Code No. |

Model |

Measurement Range

(Fixed-Type mm) |

Mass

(kg) |

|---|

| DA101 |

810-1 |

100 – 450 |

4.3 |

|---|

| DA102 |

810-2 |

200 – 600 |

10 |

|---|

| DA103 |

810-3 |

270 – 800 |

13 |

|---|

| DA104 |

810-4 |

400 – 1050 |

26 |

|---|

| DA105 |

810-5 |

450 – 1400 |

34 |

|---|

| DA106 |

810-6 |

700 – 1600 |

38 |

|---|

| DA107 |

810-7 |

1200 – 1900 |

59 |

|---|

| DA108 |

810-8 |

1400 – 2000 |

60 |

|---|

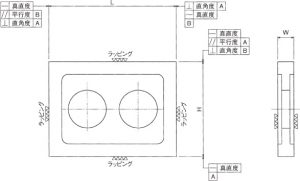

- Measurement of Surface Plate Flatness, Straightness etc can be done easily.

- At 3 points of the fulcrum interval 100mm, flat surface unevenness is measured

- Before measurement, perform zero setting on the master surface plate.

*Dial Gauge is sold separately.

Main Equipment

| Code No. |

Nominal Measurement |

Measurement

(L×W×H mm) |

Measurement Pitch

(mm) |

Mass

(kg) |

|---|

| CB101 |

200 |

240×60×90 |

100 |

4.5 |

|---|

Master Surface Plate

| Code No. |

Nominal Measurement |

Measurement

(L×W×H mm) |

Flatness

(μm) |

Mass

(kg) |

|---|

| CB102 |

300 |

300×75×150 |

1 |

10 |

|---|

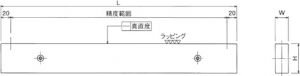

- On the granite standard straight edge lower surface, 3 saddle supports are attached.

- The accuracy surface is high precision and light weight.

- By moving the slider, straightness can easily be measured.

- By performing Zero setting on the master surface plate, it is possible to measure the work absolute value

- Rather than a dial gauge, by using a proble with external output, it is possible to perform data processing.

*Dial Gauge is sold separately.

Main Equipment

| Code No. |

Nominal Measurement |

Measurement

(L×W×H mm) |

Effective Measurement Lenght

(mm) |

Straightness

(μm) |

Mass

(kg) |

|---|

| CA101 |

500 |

640×60×125 |

500 |

2 |

18 |

|---|

| CA102 |

1000 |

1140×60×125 |

1000 |

4 |

30 |

|---|

Master Surface Plate

| Code No. |

Nominal Measurement |

Measurement

(L×W×H mm) |

Flatness

(μm) |

Mass

(kg) |

|---|

| CA201 |

500 |

640×125×110 |

1.5 |

25 |

|---|

| CA202 |

1000 |

1140×125×110 |

3.0 |

44 |

|---|