Product Detail :

VersaCam™ Swing Clamp Features

- Large ball and cam rotational mechanism assures the swing action

- VersaCam™ models swing 90°, swing angles of less than 90° readily available for a small additional charge. Swings of more than 90° are special order products

- The original "duck billed," cross bolt locking, top cap screw arm design, as originated by Vektek, is highly recommended due to its low mass, versatility, and ease of modification.

- Special wipers and swept-line cylinder top prevents chips from packing and coolant contaminants from entering the operation

- Vent port with bronze filter gives the cylinder a place to "breathe" and helps keep chips and coolants from sucking past wipers (Unclamp port on double-acting models)

|

- Exclusive BHC™ (Black Hard Coating) on the cylinder bodies and rod bearing surface helps prevent leaks caused by scoring and scratching especially in the event of high side or "kick" loads which promote excessive scoring in many other brands. BHC™ gives a Rockwell 60C skin hardness.

- Hardened Chrome alloy steel plungers run longer with less wear and drag than other brands

- Proprietary seal designs reduce leakage and increase seal life for longer lasting, more dependable operations

|

Patented V-groove cam design

- V shaped design provides a tougher mechanism. The ball runs deep in the track eliminating cam to ball edge loading

- Resists flow related damage better than our previous design (Please follow recommended flow rates for longest swing clamp life)

- Lasts longer and will withstand operator induced "crashes" from improperly loaded parts with less damage

- Provides planar rather than edge contact with the cam follower

- Will withstand swing interference better than other cam designs

- External cam swing clamp models (all standard swing clamps except High Capacity, Low Profile) have hardened V-cam tracks that resist damage and give you a built in extra cam (opposite swing direction) or straight line option should you accidentally damage one. Specify left, right or straight cam and we will preset the swing when you order

|

- Internal cam swing clamps (High Capacity, Low Profile models) have double V-cams providing extra strength, but must be ordered in the required swing direction. Low profile 5,000 and 7,500 lb. swing clamps do not have built in multiple direction cams

- Vektek again changes the "state of the art" in ball and cam swing clamps making them work better at reasonable prices

|

Threaded Body VersaCam™ Swing Clamp Specifications

Threaded Body Long Stroke VersaCam™ Swing Clamp Specifications

Flow Control VersaCam™ Swing Clamps Specifications

- Available in our popular 1100 lb. capacity model

- Integral flow control needle valve regulates the speed in both directions

- Created for applications where multiple clamps must be timed to contact the part at similar times

- Needle valve is built into the clamp head, no need to add external flow controls or give up space on your fixture for additional plumbing

- Standard Arm Clocking feature uses standard Vektek Arms

- Arms sold separately

- Special limiting capability prevents the total blockage of the flow path.

- Hardened V-cam tracks resist damage and give you a built in extra cam (opposite swing direction) or straight-line option should you accidentally damage one. Specify right, left or straight cam, we will preset the swing when you order.

- Mounting hardware is available or you may tap your fixture and use a retaining collar to lock in place.

- Standard SAE 4 O-ring porting makes plumbing simpler

and leak-free.

- Available only as a double-acting unit, springs cannot be used in this design.

Note: Do not modify the needle valve or seat, excessive pressures may result.

|

|

| Model No. | Cylinder Capacity (lb.)*** | Vertical Clamping Stroke (in.)*** | Total Stroke (Swing + Vertical) | Body Thread | Standard Arm Length | Effective Piston Area (sq.in.) | Oil Capacity**** (cu.in.) |

|---|

| Extend | Retract |

|---|

|

15-0209-09-L

15-0209-09-R

15-0209-09-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

15-0209-29-L

15-0209-29-R

15-0209-29-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

Top Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Bottom Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Cartridge Mount VersaCam™ Swing Clamps Specifications

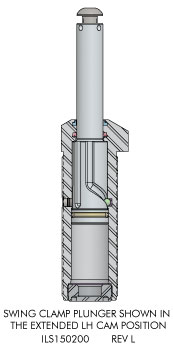

Swing Clamp plunger shown in the

extended LH cam position.

|

|

|

All dimensions are in inches. |

VersaCam™ Swing Clamp Features

- Large ball and cam rotational mechanism assures the swing action

- VersaCam™ models swing 90°, swing angles of less than 90° readily available for a small additional charge. Swings of more than 90° are special order products

- The original "duck billed," cross bolt locking, top cap screw arm design, as originated by Vektek, is highly recommended due to its low mass, versatility, and ease of modification.

- Special wipers and swept-line cylinder top prevents chips from packing and coolant contaminants from entering the operation

- Vent port with bronze filter gives the cylinder a place to "breathe" and helps keep chips and coolants from sucking past wipers (Unclamp port on double-acting models)

|

- Exclusive BHC™ (Black Hard Coating) on the cylinder bodies and rod bearing surface helps prevent leaks caused by scoring and scratching especially in the event of high side or "kick" loads which promote excessive scoring in many other brands. BHC™ gives a Rockwell 60C skin hardness.

- Hardened Chrome alloy steel plungers run longer with less wear and drag than other brands

- Proprietary seal designs reduce leakage and increase seal life for longer lasting, more dependable operations

|

Patented V-groove cam design

- V shaped design provides a tougher mechanism. The ball runs deep in the track eliminating cam to ball edge loading

- Resists flow related damage better than our previous design (Please follow recommended flow rates for longest swing clamp life)

- Lasts longer and will withstand operator induced "crashes" from improperly loaded parts with less damage

- Provides planar rather than edge contact with the cam follower

- Will withstand swing interference better than other cam designs

- External cam swing clamp models (all standard swing clamps except High Capacity, Low Profile) have hardened V-cam tracks that resist damage and give you a built in extra cam (opposite swing direction) or straight line option should you accidentally damage one. Specify left, right or straight cam and we will preset the swing when you order

|

- Internal cam swing clamps (High Capacity, Low Profile models) have double V-cams providing extra strength, but must be ordered in the required swing direction. Low profile 5,000 and 7,500 lb. swing clamps do not have built in multiple direction cams

- Vektek again changes the "state of the art" in ball and cam swing clamps making them work better at reasonable prices

|

Threaded Body VersaCam™ Swing Clamp Specifications

Threaded Body Long Stroke VersaCam™ Swing Clamp Specifications

Flow Control VersaCam™ Swing Clamps Specifications

- Available in our popular 1100 lb. capacity model

- Integral flow control needle valve regulates the speed in both directions

- Created for applications where multiple clamps must be timed to contact the part at similar times

- Needle valve is built into the clamp head, no need to add external flow controls or give up space on your fixture for additional plumbing

- Standard Arm Clocking feature uses standard Vektek Arms

- Arms sold separately

- Special limiting capability prevents the total blockage of the flow path.

- Hardened V-cam tracks resist damage and give you a built in extra cam (opposite swing direction) or straight-line option should you accidentally damage one. Specify right, left or straight cam, we will preset the swing when you order.

- Mounting hardware is available or you may tap your fixture and use a retaining collar to lock in place.

- Standard SAE 4 O-ring porting makes plumbing simpler

and leak-free.

- Available only as a double-acting unit, springs cannot be used in this design.

Note: Do not modify the needle valve or seat, excessive pressures may result.

|

|

| Model No. | Cylinder Capacity (lb.)*** | Vertical Clamping Stroke (in.)*** | Total Stroke (Swing + Vertical) | Body Thread | Standard Arm Length | Effective Piston Area (sq.in.) | Oil Capacity**** (cu.in.) |

|---|

| Extend | Retract |

|---|

|

15-0209-09-L

15-0209-09-R

15-0209-09-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

15-0209-29-L

15-0209-29-R

15-0209-29-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

Top Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Bottom Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Cartridge Mount VersaCam™ Swing Clamps Specifications

Swing Clamp plunger shown in the

extended LH cam position.

|

|

|

All dimensions are in inches. |

VersaCam™ Swing Clamp Features

- Large ball and cam rotational mechanism assures the swing action

- VersaCam™ models swing 90°, swing angles of less than 90° readily available for a small additional charge. Swings of more than 90° are special order products

- The original "duck billed," cross bolt locking, top cap screw arm design, as originated by Vektek, is highly recommended due to its low mass, versatility, and ease of modification.

- Special wipers and swept-line cylinder top prevents chips from packing and coolant contaminants from entering the operation

- Vent port with bronze filter gives the cylinder a place to "breathe" and helps keep chips and coolants from sucking past wipers (Unclamp port on double-acting models)

|

- Exclusive BHC™ (Black Hard Coating) on the cylinder bodies and rod bearing surface helps prevent leaks caused by scoring and scratching especially in the event of high side or "kick" loads which promote excessive scoring in many other brands. BHC™ gives a Rockwell 60C skin hardness.

- Hardened Chrome alloy steel plungers run longer with less wear and drag than other brands

- Proprietary seal designs reduce leakage and increase seal life for longer lasting, more dependable operations

|

Patented V-groove cam design

- V shaped design provides a tougher mechanism. The ball runs deep in the track eliminating cam to ball edge loading

- Resists flow related damage better than our previous design (Please follow recommended flow rates for longest swing clamp life)

- Lasts longer and will withstand operator induced "crashes" from improperly loaded parts with less damage

- Provides planar rather than edge contact with the cam follower

- Will withstand swing interference better than other cam designs

- External cam swing clamp models (all standard swing clamps except High Capacity, Low Profile) have hardened V-cam tracks that resist damage and give you a built in extra cam (opposite swing direction) or straight line option should you accidentally damage one. Specify left, right or straight cam and we will preset the swing when you order

|

- Internal cam swing clamps (High Capacity, Low Profile models) have double V-cams providing extra strength, but must be ordered in the required swing direction. Low profile 5,000 and 7,500 lb. swing clamps do not have built in multiple direction cams

- Vektek again changes the "state of the art" in ball and cam swing clamps making them work better at reasonable prices

|

Threaded Body VersaCam™ Swing Clamp Specifications

Threaded Body Long Stroke VersaCam™ Swing Clamp Specifications

Flow Control VersaCam™ Swing Clamps Specifications

- Available in our popular 1100 lb. capacity model

- Integral flow control needle valve regulates the speed in both directions

- Created for applications where multiple clamps must be timed to contact the part at similar times

- Needle valve is built into the clamp head, no need to add external flow controls or give up space on your fixture for additional plumbing

- Standard Arm Clocking feature uses standard Vektek Arms

- Arms sold separately

- Special limiting capability prevents the total blockage of the flow path.

- Hardened V-cam tracks resist damage and give you a built in extra cam (opposite swing direction) or straight-line option should you accidentally damage one. Specify right, left or straight cam, we will preset the swing when you order.

- Mounting hardware is available or you may tap your fixture and use a retaining collar to lock in place.

- Standard SAE 4 O-ring porting makes plumbing simpler

and leak-free.

- Available only as a double-acting unit, springs cannot be used in this design.

Note: Do not modify the needle valve or seat, excessive pressures may result.

|

|

| Model No. | Cylinder Capacity (lb.)*** | Vertical Clamping Stroke (in.)*** | Total Stroke (Swing + Vertical) | Body Thread | Standard Arm Length | Effective Piston Area (sq.in.) | Oil Capacity**** (cu.in.) |

|---|

| Extend | Retract |

|---|

|

15-0209-09-L

15-0209-09-R

15-0209-09-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

15-0209-29-L

15-0209-29-R

15-0209-29-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

Top Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Bottom Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Cartridge Mount VersaCam™ Swing Clamps Specifications

Swing Clamp plunger shown in the

extended LH cam position.

|

|

|

All dimensions are in inches. |

VersaCam™ Swing Clamp Features

- Large ball and cam rotational mechanism assures the swing action

- VersaCam™ models swing 90°, swing angles of less than 90° readily available for a small additional charge. Swings of more than 90° are special order products

- The original "duck billed," cross bolt locking, top cap screw arm design, as originated by Vektek, is highly recommended due to its low mass, versatility, and ease of modification.

- Special wipers and swept-line cylinder top prevents chips from packing and coolant contaminants from entering the operation

- Vent port with bronze filter gives the cylinder a place to "breathe" and helps keep chips and coolants from sucking past wipers (Unclamp port on double-acting models)

|

- Exclusive BHC™ (Black Hard Coating) on the cylinder bodies and rod bearing surface helps prevent leaks caused by scoring and scratching especially in the event of high side or "kick" loads which promote excessive scoring in many other brands. BHC™ gives a Rockwell 60C skin hardness.

- Hardened Chrome alloy steel plungers run longer with less wear and drag than other brands

- Proprietary seal designs reduce leakage and increase seal life for longer lasting, more dependable operations

|

Patented V-groove cam design

- V shaped design provides a tougher mechanism. The ball runs deep in the track eliminating cam to ball edge loading

- Resists flow related damage better than our previous design (Please follow recommended flow rates for longest swing clamp life)

- Lasts longer and will withstand operator induced "crashes" from improperly loaded parts with less damage

- Provides planar rather than edge contact with the cam follower

- Will withstand swing interference better than other cam designs

- External cam swing clamp models (all standard swing clamps except High Capacity, Low Profile) have hardened V-cam tracks that resist damage and give you a built in extra cam (opposite swing direction) or straight line option should you accidentally damage one. Specify left, right or straight cam and we will preset the swing when you order

|

- Internal cam swing clamps (High Capacity, Low Profile models) have double V-cams providing extra strength, but must be ordered in the required swing direction. Low profile 5,000 and 7,500 lb. swing clamps do not have built in multiple direction cams

- Vektek again changes the "state of the art" in ball and cam swing clamps making them work better at reasonable prices

|

Threaded Body VersaCam™ Swing Clamp Specifications

Threaded Body Long Stroke VersaCam™ Swing Clamp Specifications

Flow Control VersaCam™ Swing Clamps Specifications

- Available in our popular 1100 lb. capacity model

- Integral flow control needle valve regulates the speed in both directions

- Created for applications where multiple clamps must be timed to contact the part at similar times

- Needle valve is built into the clamp head, no need to add external flow controls or give up space on your fixture for additional plumbing

- Standard Arm Clocking feature uses standard Vektek Arms

- Arms sold separately

- Special limiting capability prevents the total blockage of the flow path.

- Hardened V-cam tracks resist damage and give you a built in extra cam (opposite swing direction) or straight-line option should you accidentally damage one. Specify right, left or straight cam, we will preset the swing when you order.

- Mounting hardware is available or you may tap your fixture and use a retaining collar to lock in place.

- Standard SAE 4 O-ring porting makes plumbing simpler

and leak-free.

- Available only as a double-acting unit, springs cannot be used in this design.

Note: Do not modify the needle valve or seat, excessive pressures may result.

|

|

| Model No. | Cylinder Capacity (lb.)*** | Vertical Clamping Stroke (in.)*** | Total Stroke (Swing + Vertical) | Body Thread | Standard Arm Length | Effective Piston Area (sq.in.) | Oil Capacity**** (cu.in.) |

|---|

| Extend | Retract |

|---|

|

15-0209-09-L

15-0209-09-R

15-0209-09-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

15-0209-29-L

15-0209-29-R

15-0209-29-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

Top Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Bottom Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Cartridge Mount VersaCam™ Swing Clamps Specifications

Swing Clamp plunger shown in the

extended LH cam position.

|

|

|

All dimensions are in inches. |

VersaCam™ Swing Clamp Features

- Large ball and cam rotational mechanism assures the swing action

- VersaCam™ models swing 90°, swing angles of less than 90° readily available for a small additional charge. Swings of more than 90° are special order products

- The original "duck billed," cross bolt locking, top cap screw arm design, as originated by Vektek, is highly recommended due to its low mass, versatility, and ease of modification.

- Special wipers and swept-line cylinder top prevents chips from packing and coolant contaminants from entering the operation

- Vent port with bronze filter gives the cylinder a place to "breathe" and helps keep chips and coolants from sucking past wipers (Unclamp port on double-acting models)

|

- Exclusive BHC™ (Black Hard Coating) on the cylinder bodies and rod bearing surface helps prevent leaks caused by scoring and scratching especially in the event of high side or "kick" loads which promote excessive scoring in many other brands. BHC™ gives a Rockwell 60C skin hardness.

- Hardened Chrome alloy steel plungers run longer with less wear and drag than other brands

- Proprietary seal designs reduce leakage and increase seal life for longer lasting, more dependable operations

|

Patented V-groove cam design

- V shaped design provides a tougher mechanism. The ball runs deep in the track eliminating cam to ball edge loading

- Resists flow related damage better than our previous design (Please follow recommended flow rates for longest swing clamp life)

- Lasts longer and will withstand operator induced "crashes" from improperly loaded parts with less damage

- Provides planar rather than edge contact with the cam follower

- Will withstand swing interference better than other cam designs

- External cam swing clamp models (all standard swing clamps except High Capacity, Low Profile) have hardened V-cam tracks that resist damage and give you a built in extra cam (opposite swing direction) or straight line option should you accidentally damage one. Specify left, right or straight cam and we will preset the swing when you order

|

- Internal cam swing clamps (High Capacity, Low Profile models) have double V-cams providing extra strength, but must be ordered in the required swing direction. Low profile 5,000 and 7,500 lb. swing clamps do not have built in multiple direction cams

- Vektek again changes the "state of the art" in ball and cam swing clamps making them work better at reasonable prices

|

Threaded Body VersaCam™ Swing Clamp Specifications

Threaded Body Long Stroke VersaCam™ Swing Clamp Specifications

Flow Control VersaCam™ Swing Clamps Specifications

- Available in our popular 1100 lb. capacity model

- Integral flow control needle valve regulates the speed in both directions

- Created for applications where multiple clamps must be timed to contact the part at similar times

- Needle valve is built into the clamp head, no need to add external flow controls or give up space on your fixture for additional plumbing

- Standard Arm Clocking feature uses standard Vektek Arms

- Arms sold separately

- Special limiting capability prevents the total blockage of the flow path.

- Hardened V-cam tracks resist damage and give you a built in extra cam (opposite swing direction) or straight-line option should you accidentally damage one. Specify right, left or straight cam, we will preset the swing when you order.

- Mounting hardware is available or you may tap your fixture and use a retaining collar to lock in place.

- Standard SAE 4 O-ring porting makes plumbing simpler

and leak-free.

- Available only as a double-acting unit, springs cannot be used in this design.

Note: Do not modify the needle valve or seat, excessive pressures may result.

|

|

| Model No. | Cylinder Capacity (lb.)*** | Vertical Clamping Stroke (in.)*** | Total Stroke (Swing + Vertical) | Body Thread | Standard Arm Length | Effective Piston Area (sq.in.) | Oil Capacity**** (cu.in.) |

|---|

| Extend | Retract |

|---|

|

15-0209-09-L

15-0209-09-R

15-0209-09-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

15-0209-29-L

15-0209-29-R

15-0209-29-S

|

1100 |

0.31 |

0.79 |

1 1/2-16 |

1.50 |

0.295 |

0.475 |

0.233 |

|

Top Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Bottom Flange/Manifold Mount VersaCam™ Swing Clamp Specifications

Cartridge Mount VersaCam™ Swing Clamps Specifications

Swing Clamp plunger shown in the

extended LH cam position.

|

|

|

All dimensions are in inches. |