E-Catalog > VEKTEK USA > TuffCam™ Swing Clamps

Product Detail :

TuffCam™ Swing Clamps

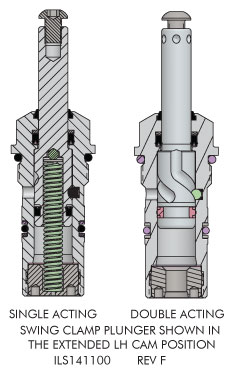

Standard Features

|

TuffCam™ Swing Clamps meet your demand for a product that can handle the stress and positioning requirements of high-speed or heavy arm applications. These tri-cam design clamps, with their patented Cam Follower Seat, can position and clamp in one second or less, handle large arms with ease and include the Clocking feature that dramatically reduces the time it takes to change arms for maintenance, replacement or fixture setup.

Available in these body styles:

|

Low Profile |

Position sensing clamps are double acting only.

TuffCam™ Threaded Body Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All dimensions are in inches.

Warning! Never allow swing arm to contact workpiece or fixture during arm rotation.

TuffCam™ Top Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Top Flange Long Stroke

Specifications

|

Swing restrictors available. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Long Stroke

Specifications

|

|

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Cartridge Mount Swing Clamps

Specifications

|

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Rod Position Sensing Swing Clamp

|

Swing Restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Magnetic Position Sensing System Swing Clamps

| |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Top Flange Swing Clamps

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Bottom Flange Swing Clamps

Optional in-port flow control is a meter-in

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Rod Position Sensing Swing Clamp

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Position Sensing Swing Clamps

|

The use of NPN or PNP is determined by the type of control unit to which the sensor is connected. One Sensor is required for each sensing position. |

|||

Sensor Kits Ordered Separately

|

Sensor Features

|

|||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Swing Clamps

Standard Features

|

TuffCam™ Swing Clamps meet your demand for a product that can handle the stress and positioning requirements of high-speed or heavy arm applications. These tri-cam design clamps, with their patented Cam Follower Seat, can position and clamp in one second or less, handle large arms with ease and include the Clocking feature that dramatically reduces the time it takes to change arms for maintenance, replacement or fixture setup.

Available in these body styles:

|

Low Profile |

Position sensing clamps are double acting only.

TuffCam™ Threaded Body Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All dimensions are in inches.

Warning! Never allow swing arm to contact workpiece or fixture during arm rotation.

TuffCam™ Top Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Top Flange Long Stroke

Specifications

|

Swing restrictors available. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Long Stroke

Specifications

|

|

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Cartridge Mount Swing Clamps

Specifications

|

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Rod Position Sensing Swing Clamp

|

Swing Restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Magnetic Position Sensing System Swing Clamps

| |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Top Flange Swing Clamps

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Bottom Flange Swing Clamps

Optional in-port flow control is a meter-in

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Rod Position Sensing Swing Clamp

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Position Sensing Swing Clamps

|

The use of NPN or PNP is determined by the type of control unit to which the sensor is connected. One Sensor is required for each sensing position. |

|||

Sensor Kits Ordered Separately

|

Sensor Features

|

|||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Swing Clamps

Standard Features

|

TuffCam™ Swing Clamps meet your demand for a product that can handle the stress and positioning requirements of high-speed or heavy arm applications. These tri-cam design clamps, with their patented Cam Follower Seat, can position and clamp in one second or less, handle large arms with ease and include the Clocking feature that dramatically reduces the time it takes to change arms for maintenance, replacement or fixture setup.

Available in these body styles:

|

Low Profile |

Position sensing clamps are double acting only.

TuffCam™ Threaded Body Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All dimensions are in inches.

Warning! Never allow swing arm to contact workpiece or fixture during arm rotation.

TuffCam™ Top Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Top Flange Long Stroke

Specifications

|

Swing restrictors available. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Long Stroke

Specifications

|

|

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Cartridge Mount Swing Clamps

Specifications

|

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Rod Position Sensing Swing Clamp

|

Swing Restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Magnetic Position Sensing System Swing Clamps

| |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Top Flange Swing Clamps

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Bottom Flange Swing Clamps

Optional in-port flow control is a meter-in

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Rod Position Sensing Swing Clamp

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Position Sensing Swing Clamps

|

The use of NPN or PNP is determined by the type of control unit to which the sensor is connected. One Sensor is required for each sensing position. |

|||

Sensor Kits Ordered Separately

|

Sensor Features

|

|||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Swing Clamps

Standard Features

|

TuffCam™ Swing Clamps meet your demand for a product that can handle the stress and positioning requirements of high-speed or heavy arm applications. These tri-cam design clamps, with their patented Cam Follower Seat, can position and clamp in one second or less, handle large arms with ease and include the Clocking feature that dramatically reduces the time it takes to change arms for maintenance, replacement or fixture setup.

Available in these body styles:

|

Low Profile |

Position sensing clamps are double acting only.

TuffCam™ Threaded Body Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All dimensions are in inches.

Warning! Never allow swing arm to contact workpiece or fixture during arm rotation.

TuffCam™ Top Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Top Flange Long Stroke

Specifications

|

Swing restrictors available. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Long Stroke

Specifications

|

|

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Cartridge Mount Swing Clamps

Specifications

|

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Rod Position Sensing Swing Clamp

|

Swing Restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Magnetic Position Sensing System Swing Clamps

| |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Top Flange Swing Clamps

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Bottom Flange Swing Clamps

Optional in-port flow control is a meter-in

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Rod Position Sensing Swing Clamp

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Position Sensing Swing Clamps

|

The use of NPN or PNP is determined by the type of control unit to which the sensor is connected. One Sensor is required for each sensing position. |

|||

Sensor Kits Ordered Separately

|

Sensor Features

|

|||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Swing Clamps

Standard Features

|

TuffCam™ Swing Clamps meet your demand for a product that can handle the stress and positioning requirements of high-speed or heavy arm applications. These tri-cam design clamps, with their patented Cam Follower Seat, can position and clamp in one second or less, handle large arms with ease and include the Clocking feature that dramatically reduces the time it takes to change arms for maintenance, replacement or fixture setup.

Available in these body styles:

|

Low Profile |

Position sensing clamps are double acting only.

TuffCam™ Threaded Body Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All dimensions are in inches.

Warning! Never allow swing arm to contact workpiece or fixture during arm rotation.

TuffCam™ Top Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Top Flange Long Stroke

Specifications

|

Swing restrictors available. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Swing Clamps

Specifications

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Bottom Flange Long Stroke

Specifications

|

|

Optional in-port flow control is a meter-in

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Cartridge Mount Swing Clamps

Specifications

|

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Rod Position Sensing Swing Clamp

|

Swing Restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Magnetic Position Sensing System Swing Clamps

| |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Top Flange Swing Clamps

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Bottom Flange Swing Clamps

Optional in-port flow control is a meter-in

|

Swing restrictors available. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TuffCam™ Low Profile Rod Position Sensing Swing Clamp

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Position Sensing Swing Clamps

|

The use of NPN or PNP is determined by the type of control unit to which the sensor is connected. One Sensor is required for each sensing position. |

|||

Sensor Kits Ordered Separately

|

Sensor Features

|

|||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||