E-Catalog > MicroCentric > จำหน่ายสินค้า MicroCentric

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- MicroCentric

- สินค้า, ผลิตภัณฑ์

Product Detail :

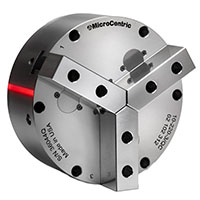

Precision Air Chuck Models

-

Rotating air chucks are ideal for precision turning and cylindrical grinding applications that require close concentricity, squareness, and parallelism tolerances. Variable clamping force enables clamping of thin-walled and other fragile parts with minimal distortion. All models, except the 3-50, feature a coolant or air passage through the center of the chuck.

Chuck Accuracy- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

-

Stationary air chucks are ideal for milling, drilling, tapping, and other applications requiring a compact self-contained workholding fixture. Air is supplied directly into the side of the chuck body, and the chuck can be mounted directly to the machine table or pallet. Through holes are available on all models.

Chuck Accuracy- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

-

Long stroke air chucks feature extended jaw opening for load clearance or to clamp a range of diameters without changing top jaws. Long stroke chucks are available in rotating and stationary configurations. Their high accuracy makes them ideal for clamping headed workpieces for turning, grinding, or milling/drilling applications. Special models with total jaw stroke of .500" (12.7mm), .750" (19.1mm), and 1.000" (24.5mm) are also available. Please call for information.

Chuck Accuracy- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

-

HST High Speed Air Chucks feature a titanium chuck body and are actuated by a patented external wedge design that maintains clamping force at high spindle speeds without counterweights. This revolutionary design minimizes the effects of centrifugal force resulting in consistent clamping force throughout the chuck's rpm range.

HST chucks are available in standard, HS, and BP models. The HS models are dynamically balanced and feature MicroCentric's patented NR50 non-rotating air tube system. The NR50 design eliminates vibra tion caused by rotating air at higher spindle speeds, thus enhancing a machine's surface finish, and roundness capability.

Chuck Accuracy- .0001" (0.0025mm) TIR is standard

- .00005" (0.0012mm) TIR is available

-

Sealed air chucks feature a stainless steel cover that seals the jaw slides. This design prevents contamination from grit and swarf and minimizes chuck maintenance for high volume production operations. Sealed air chucks are available in rotating and stationary configurations and are ideal for cylindrical grinding operations as well as machining abrasive materials such as powdered metal, ceramic, or carbide.

QC precision located top jaw system is standard on sealed air chucks.

Chuck Accuracy- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

-

Large Diameter Air Chucks offer high accuracy and adjustable clamping force for machining large diameter precision and thin-walled workpieces. Large Diameter chucks are availalbe in three jaw as well as two and six jaw configurations. Large Diameter models with extended jaw stroke, air ports on OD of chuck body for stationary applications, and other special configurations are quoted upon request.

Chuck Accuracy- .0002" (0.005mm) TIR is standard

- .0001" (0.0025mm) TIR is available

Rotating Air Chucks

Rotating air chucks are ideal for precision turning and cylindrical grinding applications that require close concentricity, squareness, and parallelism tolerances. Variable clamping force enables clamping of thin-walled and other fragile parts with minimal distortion. All models, except the 3-50, feature a coolant or air passage through the center of the chuck.

Chuck Accuracy

- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

| 3-50-3 | 3 in80 mm | 3 | .00005 in.0012 mm | .050 in1.3 mm | 920 lbs4.1 kN | 100 psi0.7 MPa | 6,000 | 3 lb1.4 kg |

| 3-50C-3 | 3 in80 mm | 3 | .00005 in.0012 mm | .050 in1.3 mm | 920 lbs4.1 kN | 100 psi0.7 MPa | 6,000 | 3 lb1.4 kg |

| 4-40-3 | 4 in100 mm | 3 | .00005 in.0012 mm | .040 in1.0 mm | 1,520 lbs6.8 kN | 100 psi0.7 MPa | 6,000 | 6.1 lb2.8 kg |

| 4-120-3 | 4 in100 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 1,520 lbs6.8 kN | 100 psi0.7 MPa | 6,000 | 6.9 lb3.1 kg |

| 6-40-3 | 6 in150 mm | 3 | .00005 in.0012 mm | .040 in1.0 mm | 3,820 lbs17.0 kN | 100 psi0.7 MPa | 4,000 | 14.1 lb6.4 kg |

| 6-120-3 | 6 in150 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 3,820 lbs17.0 kN | 100 psi0.7 MPa | 4,000 | 15.9 lb7.2 kg |

| 8-120-3 | 8 in200 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 6,570 lbs29.2 kN | 100 psi0.7 MPa | 3,500 | 42.2 lb19.1 kg |

| 10-220-3 | 10 in250 mm | 3 | .00005 in.0012 mm | .220 in5.6 mm | 10,330 lbs46.0 kN | 100 psi0.7 MPa | 3,000 | 75.2 lb34.1 kg |

Large Diameter Air Chucks

Large Diameter Air Chucks offer high accuracy and adjustable clamping force for machining large diameter precision and thin-walled workpieces. Large Diameter chucks are availalbe in three jaw as well as two and six jaw configurations. Large Diameter models with extended jaw stroke, air ports on OD of chuck body for stationary applications, and other special configurations are quoted upon request.

Chuck Accuracy

- .0002" (0.005mm) TIR is standard

- .0001" (0.0025mm) TIR is available

| 12-220-3 | 12 in300 mm | 3 | .0002 in.005 mm | .220 in5.6 mm | 13,125 lbs58.4 kN | 100 psi0.7 MPa | 2,250 | 110 lb49.9 kg |

| 12-400-3 | 12 in300 mm | 3 | .0002 in.005 mm | .400 in10.2 mm | 11,250 lbs50.1 kN | 100 psi0.7 MPa | 1,850 | 110 lb49.9 kg |

| 14-220-3 | 14 in350 mm | 3 | .0002 in.005 mm | .220 in5.6 mm | 20,640 lbs91.9 kN | 100 psi0.7 MPa | 2,250 | 156 lb70.8 kg |

| 14-400-3 | 14 in350 mm | 3 | .0002 in.005 mm | .400 in10.2 mm | 17,690 lbs78.7 kN | 100 psi0.7 MPa | 1,850 | 156 lb70.8 kg |

| 16-220-3 | 16 in400 mm | 3 | .0002 in.005 mm | .220 in5.6 mm | 23,520 lbs104.7 kN | 100 psi0.7 MPa | 2,000 | 257 lb116.6 kg |

| 16-400-3 | 16 in400 mm | 3 | .0002 in.005 mm | .400 in10.2 mm | 20,160 lbs89.7 kN | 100 psi0.7 MPa | 1,500 | 257 lb116.6 kg |

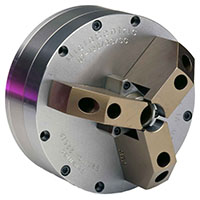

Sealed Air Chucks

Sealed air chucks feature a stainless steel cover that seals the jaw slides. This design prevents contamination from grit and swarf and minimizes chuck maintenance for high volume production operations. Sealed air chucks are available in rotating and stationary configurations and are ideal for cylindrical grinding operations as well as machining abrasive materials such as powdered metal, ceramic, or carbide.

QC precision located top jaw system is standard on sealed air chucks.

Chuck Accuracy

- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

Model |

Chuck Size |

No. of Jaws |

Chuck Accuracy |

Jaw Stroke |

Max. Clamp Force |

Max. Air Pressure |

Max. rpm |

Chuck Weight |

|---|---|---|---|---|---|---|---|---|

| SC/34-50-3/QC | 3 in80 mm | 3 | .00005 in.0012 mm | .050 in1.3 mm | 1,520 lbs6.8 kN | 100 psi0.7 MPa | 6,000 | 4.2 lb1.9 kg |

| SC/45-120-3/QC | 4 in100 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 2,710 lbs12.1 kN | 100 psi0.7 MPa | 6,000 | 9.5 lb4.3 kg |

| SC/67-120-3/QC | 6 in150 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 5,710 lbs25.4 kN | 100 psi0.7 MPa | 4,000 | 20.4 lb9.3 kg |

Sealed Air Chucks

Sealed air chucks feature a stainless steel cover that seals the jaw slides. This design prevents contamination from grit and swarf and minimizes chuck maintenance for high volume production operations. Sealed air chucks are available in rotating and stationary configurations and are ideal for cylindrical grinding operations as well as machining abrasive materials such as powdered metal, ceramic, or carbide.

QC precision located top jaw system is standard on sealed air chucks.

Chuck Accuracy

- .00005" (0.0012mm) TIR is standard

- .00002" (0.0005mm) TIR is available

Model |

Chuck Size |

No. of Jaws |

Chuck Accuracy |

Jaw Stroke |

Max. Clamp Force |

Max. Air Pressure |

Max. rpm |

Chuck Weight |

|---|---|---|---|---|---|---|---|---|

| SC/34-50-3/QC | 3 in80 mm | 3 | .00005 in.0012 mm | .050 in1.3 mm | 1,520 lbs6.8 kN | 100 psi0.7 MPa | 6,000 | 4.2 lb1.9 kg |

| SC/45-120-3/QC | 4 in100 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 2,710 lbs12.1 kN | 100 psi0.7 MPa | 6,000 | 9.5 lb4.3 kg |

| SC/67-120-3/QC | 6 in150 mm | 3 | .00005 in.0012 mm | .120 in3.0 mm | 5,710 lbs25.4 kN | 100 psi0.7 MPa | 4,000 | 20.4 lb9.3 kg |

Model SC/67-120-3/QC, Sealed Air Chucks

DOWNLOADS

Sealed air chucks feature a stainless steel cover that seals the jaw slides. This design prevents contamination from grit and swarf and minimizes chuck maintenance for high volume production operations. Sealed air chucks are available in rotating and stationary configurations and are ideal for cylindrical grinding operations as well as machining abrasive materials such as powdered metal, ceramic, or carbide.

QC precision located top jaw system is standard on sealed air chucks.

Chuck Accuracy

Chuck Size |

6 in150 mm |

| No. of Jaws1 | 3 |

| Chuck Accuracy2 | .00005 in.0012 mm |

| Jaw Stroke3 | .120 in3.0 mm |

Max. Clamp Force |

5,710 lbs25.4 kN |

Max. Air Pressure |

100 psi0.7 MPa |

| Max. rpm4 | 4,000 |

Chuck Weight |

20.4 lb9.3 kg |

Item No. |

06 061 302 |

- 1 2 jaw configurations available for all air chuck sizes

- 2 Chuck accuracy is defined as the total indicator reading (maximum radial and lateral runout) of a master gage measured

- 3 Total jaw stroke (on diameter)

- 4 Max. rpm is influenced by air pressure and mass of top jaws

HST High Speed Air Chucks

HST High Speed Air Chucks feature a titanium chuck body and are actuated by a patented external wedge design that maintains clamping force at high spindle speeds without counterweights. This revolutionary design minimizes the effects of centrifugal force resulting in consistent clamping force throughout the chuck's rpm range.

HST chucks are available in standard, HS, and BP models. The HS models are dynamically balanced and feature MicroCentric's patented NR50 non-rotating air tube system. The NR50 design eliminates vibra tion caused by rotating air at higher spindle speeds, thus enhancing a machine's surface finish, and roundness capability.

Chuck Accuracy

- .0001" (0.0025mm) TIR is standard

- .00005" (0.0012mm) TIR is available

.jpg)