E-Catalog > TAC Rockford for machine Tools > Preventive Maintenance Gauges

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- TAC Rockford for machine Tools

- สินค้า, ผลิตภัณฑ์

Product Detail :

Machine Tool Gauges

TAC Rockford offers the world's largest variety of gauges and preventive maintenance tools for the machine tool industry designed to detect problems in machining centers before they become serious. Products include the ForceCheck gage for measuring tool holder clamping force, spindle run-out test bars, tool changer alignment tools, collet and chuck force measurement tools, and spindle and tool holder dimensional gauges.

Milling Spindle

TAC Rockford offers several gauges to keep your HSK, Steep Taper, Capto, KM and other CNC milling or grinding machining center spindle in top operating condition. To learn more, visit our milling spindle machine tool gauges section.

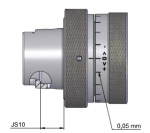

Tool Holder Taper

Units are available for CAT/DIN/BT tapers in basic contact gauges, dial indicator gauges, as well as air gauges. For HSK, we offer dial indicator, electronic, and air gauges.

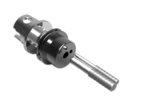

Why Check Drawbar Force?

Is your power drawbar working correctly?

Improve tool life and part finish

Correct tool holding force ensures that the spindle-tool holder interface is as rigid as possible. A rigid interface will improve tool life by reducing chatter and excess wear, and in turn improve workpiece finish.

Protect your spindles and ensure machining accuracy

Insufficient tool holding force can quickly wear or damage the critical spindle taper resulting in loss of machine accuracy and an expensive repair bill.

For the HSK taper, wear and damage on the spindle taper are even more detrimental. The HSK taper relies on an interference fit between the spindle and tool holder tapers, meaning drawbar force must be sufficient for the tool holder to properly seat. Because the HSK interface seats both on the tool holder taper and flange, dimensional tolerances are extremely tight. For HSK forms E and F, correct clamping force is crucial because there are not drive keys or dogs to transmit torque–the system relies entirely on the power drawbar's holding force.

Predict problems with the spindle's Belleville / disk spring stack

Machining centers with automatic tool clamping systems typically use Belleville/disk spring stack to hold a tool in the spindle, with a hydraulic cylinder used to overcome the spring force to unclamp the tool.

High RPM is often an important design criterion for a spindle, meaning the use of small diameter bearings makes sense from an engineering standpoint. Small bearings necessitate the use of small diameter springs to fit into the spindle arbor. Small-diameter springs lead to highly stressed springs for tool clamping, and even more so during tool unclamp.

A typical drawbar spring stack is designed to last approximately 1 million cycles. This may sound like a big number, but tool changes add up quickly. An example: a process with 3 to 4 tool changes per minute (many do much more), with 2,000 operating hours per year (one shift), means between 360,000 and 480,000 cycles are made per year. In this scenario, the springs have reached the end of the design life cycle and should be replaced after two years. We have found some processes that reach 1 million cycles after 6 months–with the complaint that the "springs break all the time."

Springs will not break all at once. Initially only one spring might break without significant impact on tool holding force. However, soon others will break since they have to do the work of the broken spring (or springs) as well. The rest of the springs will be overloaded and break or take a permanent set.

This failure process can be detected with a clamping force measuring device and action be taken before the clamping system fails completely.

Check for the role that friction plays in the clamping system and for proper lubrication

Some drawbar designs use a mechanical force intensification mechanism to increase tool holding force. When force intensification is used, friction is a factor to be watched. It is difficult to quantify friction without measurement. Machine builders typically provide a tool holding force specification for properly lubricated and adjusted clamping system.

Most power drawbar systems with HSK tapers use force intensification in the gripper design. The mechanical intensification of the force is typically between 3 and 9 times, making friction a major factor in the proper operation of the system.

For systems with manual HSK grippers such as those supplied by Mapal and Guehring, periodic verification of correct tool holding force is also of critical importance. Per manufacturer recommendation, tools should be clamped using a torque wrench to ensure correct force. However, if the gripper is not properly lubricated, tool holding force will be much lower at the specified torque.

Operator safety

Eventually, the tool holding system of a machine will fail catastrophically if left unchecked. There will be lots of mysterious problems such as poor part finish and broken tools, and eventually leading to the tool flying out of the spindle and damaging the workpiece, machine, or worse–injuring the operator.

Standards compliance

- The ISO and DIN HSK standards have recommended minimum clamping forces. The ForceCheck gauge can verify that these are met.

- The "CAT" steep taper standard ASME B5.50 specifically recommends using a drawbar force gauge.

- ISO 9000 compliance requires that critical machine parameters be periodically checked.

HSK Taper

Measuring bars, complete sets, and base sets for all HSK type spindles. Contact us for other wireless and carrying case options.

Steep Taper (SK-DIN)

Measuring bars, complete sets, and base sets for Steep Taper (SK) DIN standard. Metric or inch retention knob / pull-stud threading available on each measuring bar.

Steep Taper (CAT/ANSI)

Measuring bars, complete sets, and base sets for Steep Taper (SK) CAT-ANSI. Metric or inch retention knob / pull-stud threading available on each measuring bar.

Steep Taper (ISO)

Measuring bars, complete sets, and base units for measuring drawbar force on a Steep Taper (SK) ISO standard spindle.

PSK Capto

Measuring bars, complete sets, and base units for measuring drawbar force on Coromant Capto spindles (Polygonal Shank Taper - PSK).

KM Taper

Measuring bars, complete sets, and base units for measuring draw

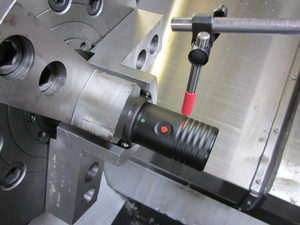

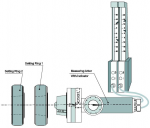

Tool Changer Alignment Gauges

Tool changer alignment gauges are used to check automatic tool changer positioning between the gripper arm, magazine, tool holder, and the spindle.

Improper alignment results in abnormal wear on spindle and tool holder tapers, faulty clamping, dropped tools, and decreased machine repeatability – resulting in reduced productivity and expensive machine damage.

Tool changer alignment gauges from TAC Rockford make correct alignment between the spindle and automatic tool changer easy.

HSK Tool Changer Alignment Gauges

Available for HSK-A 25, 32, 40, 50, 63, 80, 100, 125, and 160. Includes padded storage case.  Details

Details  PDF (440.100)

PDF (440.100)

Steep Taper Tool Changer Alignment Gauges

Available for Steep Taper 30, 40, 50, and 60. Includes padded storage case.  Details

Details  PDF (440.800)

PDF (440.800)

Capto Tool Changer Alignment Gauges

Available for Polygonal-Shank Taper (Capto) sizes C3, C4, C5, C6, C8, C8X, C10. Includes padded storage case.  Details

Details  PDF (440.C00)

PDF (440.C00)

KM Tool Changer Alignment Gauges

Sets include taper and flange, axial and radial alignment pins, and a padded carrying case.  Details

Details  PDF (440.K00)

PDF (440.K00)

| Taper | Flange | Order Number | ||||||

|---|---|---|---|---|---|---|---|---|

| KM 63 | ISO 26622 | 440.135.K63.000

|

||||||

| KM 63 | Mazak Integrex | 440.135.K63.IGX

|

||||||

| KM 100 | ISO 26622 |

|

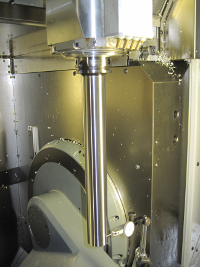

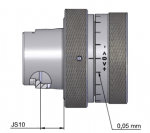

Runout Test Arbors

Spindle runout arbors offer a quick and easy way to verify that a machine spindle is running true after a crash, after a machine has been moved, or periodically as a performance check. Arbors are available for all major machine tapers, including CAT/DIN/BT Steep Taper, HSK, Capto, Morse, and others.

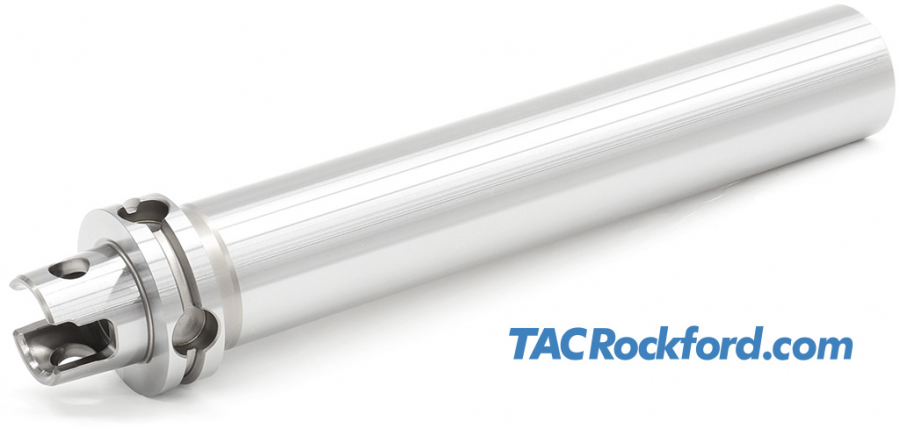

HSK Spindle Runout Test Arbors

Available for HSK-A/C/E 32, 40, 50, 65, 80, 100, 125, 160 and HSK-F 40, 50, 63, 80, 100, 125, 160  Details

Details  PDF (465.100)

PDF (465.100)

| HSK | l1 (mm) | d1 (mm) | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| HSK-A 25 | 140 | 20 | 465.125.000.000

|

|||||

| HSK-A 32 | 180 | 24 | 465.132.000.000

|

|||||

| HSK-A/C/E 40 | 200 | 25 | 465.140.000.000

|

|||||

| HSK-A/C/E 50 and HSK-F 63 | 346 | 32 | 465.150.000.000

|

|||||

| HSK-A/C/E 63 | 346 | 40 | 465.163.000.000

|

|||||

| HSK-A 80 | 346 | 40 | 465.180.000.000

|

|||||

| HSK-A 100 | 300 | 50 | 465.190.000.000

|

|||||

| HSK-A 125 | 349 | 40 | 465.192.000.000

|

|||||

| HSK-A 160 | 400 | 40 | 465.196.000.000

|

|||||

| HSK-F 63 | 346 | 40 | 465.663.000.000

|

|||||

| HSK-F 80 | 346 | 50 | 465.680.000.000

|

Steep Taper Spindle Runout Test Arbors

Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.  Details

Details  PDF (465.800)

PDF (465.800)