Product Detail :

Special Purpose Power Chucks

AUTOGRIP®'s special power chucks! Our chucks are specifically designed to clamp workpieces with unique shapes or special processing requirements, providing optimal stability and cutting efficiency for milling and drilling tasks.

We understand that every customer has different needs, which is why we offer a wide range of special chucks to choose from. Whether you require central water/gas injection, air tightness detection, or other custom functions, our team will work with you to select the perfect chuck for your application. Below are many types of special purpose power chucks for your choosing.

Contact AUTOGRIP® today to learn more about our selection of special purpose power chucks and how we can provide a customized solution for your clamping needs!

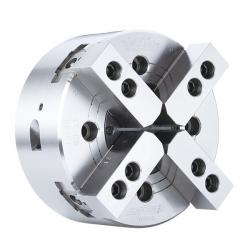

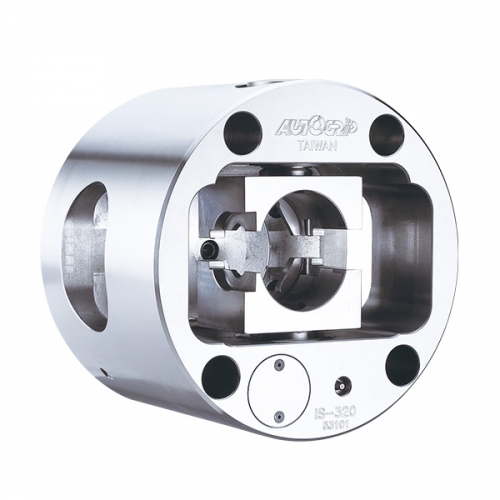

IS

| Model | Index Angle Deg | Jaw stroke (mm) | Chucking Area Dia. Max.(mm) | Chucking Area Dia. Max.(mm) | Max. pressure MPa (kgf/cm2) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | ROTATING JOINT | Main Spindle Bore(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| IS-254 | 4x90゜ | 20 | 65 | 160 | 45 | 19.5 (1990) |

2400 | 0.41 | 41.0 | IS-315 | 86+0.1 |

| IS-275 | 4x90゜ | 20 | 80 | 220 | 45 | 25.4 (2590) |

2100 | 0.61 | 52.0 | IS-315 | 86+0.1 |

| IS-315 | 4x90゜ | 20 | 100 | 230 | 45 | 25.0 (2550) |

1800 | 1.13 | 76.0 | IS-315 | 86+0.1 |

* Index Angle 8x45° or Specific Angle, Please contact AUTOGRIP for more detailed information.Thanks.

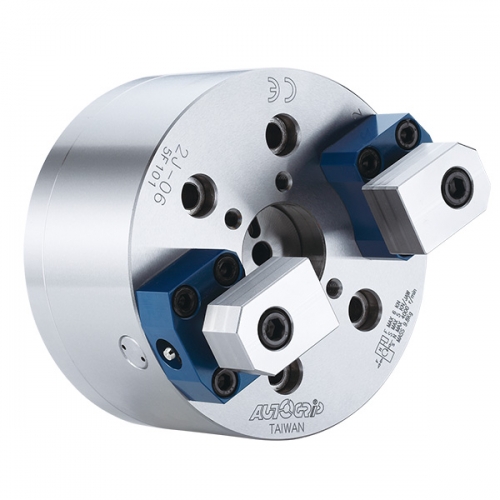

2J

| Model | Rotating stroke (mm) | Claming stroke (mm) | Jaw's compensation (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2J-05 | 12 | 8 | 2 | 53 | 25 | 5.0 (510) |

4.0 (408) |

4000 | 0.015 | 9 | RK-100 OR RK-100(N) |

0.7(7) |

| 2J-06 | 12 | 8 | 2 | 79 | 55 | 6.0 (612) |

5.0 (510) |

4000 | 0.035 | 9.8 | RK-100 OR RK-100(N) |

0.8(8) |

| 2J-08 | 12 | 8 | 2 | 106 | 75 | 12.0 (1224) |

11.0 (1122) |

3500 | 0.12 | 20.3 | RK-100 OR RK-100(N) |

1.7(17) |

| 2J-10 | 12 | 8 | 2.5 | 150 | 119 | 12.0 (1224) |

11.0 (1122) |

3500 | 0.28 | 30.7 | RK-100 OR RK-100(N) |

1.7(17) |

| 2J-12 | 12 | 8 | 2.5 | 200 | 169 | 12.0 (1224) |

11.0 (1122) |

3000 |

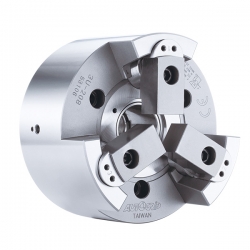

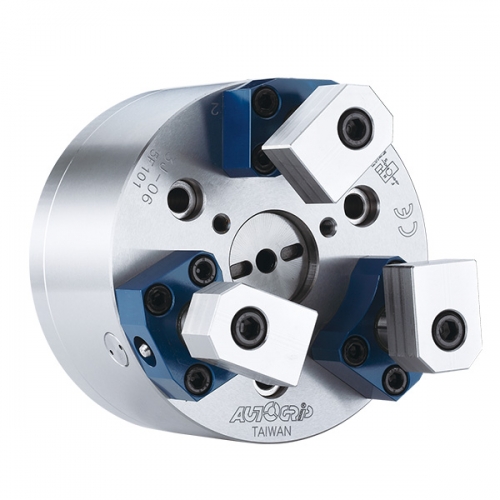

3J

| Model | Rotating stroke (mm) | Claming stroke (mm) | Jaw's compensation (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3J-05 | 12 | 8 | 2 | 53 | 25 | 7.5 (765) |

6.0 (612) |

4000 | 0.02 | 11.0 | RK-100 OR RK-100(N) |

1.0(10) |

| 3J-06 | 12 | 8 | 2 | 79 | 55 | 9.0 (918) |

7.5 (765) |

4000 | 0.04 | 12.0 | RK-100 OR RK-100(N) |

1.2(12) |

| 3J-08 | 12 | 8 | 2 | 106 | 75 | 18.0 (1835) |

16.5 (1680) |

3500 | 0.13 | 23.0 | RK-100 OR RK-100(N) |

2.5(25) |

| 3J-10 | 12 | 8 | 2.5 | 150 | 119 | 18.0 (1835) |

16.5 (1680) |

3500 | 0.3 | 33.0 | RK-100 OR RK-100(N) |

2.5(25) |

| 3J-12 | 12 | 8 | 2.5 | 200 | 169 | 18.0 (1835) |

16.5 (1680) |

3000 |

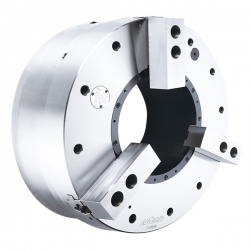

3R

| Model | Plunger stroke (mm) | Jaw stroke (Dia.)(mm) | Chucking Dia. max.(mm) | Chucking Dia. min.(mm) | Max. D.B. pull kN(kgf) | Max. clamping force kN(kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Compensation (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

3R-08

|

20 | 8 | 65 | 18 | 19.6 (2000) | 53.0 (5404) | 2800 | 0.15 | 27 | RK-100(N) | 2 |

|

3R-10

|

25 | 10 | 90 | 22 | 29.4 (3000) | 67.7 (6901) |

3W

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chuckin Dia. OD Min.~Max. (mm) | Chucking Dia. ID Min.~Max. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. |

|---|---|---|---|---|---|---|---|---|---|---|

| 3W-08 | 14.4 | 9.8 | 16~150 | 76~203 | 25.0 (2550) |

85.0 (8670) |

3700 | 0.12 | 23 | RK-100(N) |

| 3W-10 | 17.5 | 12.5 | 50~205 | 85~235 | 35.3 (3600) |

105.9 (10800) |

2500 | 0.37 | 48.6 | RK-125(N) |

| 3W-12 | 17.5 | 12.5 | 63~240 | 127~305 | 35.3 (3600) |

105.9 (10800) |

2400 | 0.73 | 65 | RK-125(N) |

| 3W-15 | 22.5 | 15.9 | 76~317 | 165~381 | 56 (5600) |

168.2 (16800) |

2000 | 1.81 | 97 |

3W-C

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chuckin Dia. OD Min.~Max. (mm) | Chucking Dia. ID Min.~Max. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Compensation (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3W-C08 | 14.4 | 9.8 | 16~150 | 76~203 | 25.0 (2550) |

85.0 (8670) |

3700 | 0.12 | 23 | RK-100(N) | 2 |

| 3W-C10 | 17.5 | 12.5 | 50~205 | 85~235 | 35.3 (3600) |

105.9 (10800) |

2500 | 0.37 | 48.6 | RK-125(N) | 2 |

| 3W-C12 | 17.5 | 12.5 | 63~240 | 127~305 | 35.3 (3600) |

105.9 (10800) |

2400 | 0.73 | 65 | RK-125(N) | 2 |

| 3W-C15 | 22.5 | 15.9 | 76~317 | 165~381 | 56 (5600) |

168.2 (16800) |

2000 | 1.81 | 97 |

3E

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3E-05 | 6 | 3 | 83 | 29 | 13.0 (1325) |

42.0 (4280) |

7000 | 0.018 | 7.5 | RK-100 | 1.8(18.5) |

| 3E-06 | 10 | 5 | 110 | 44 | 18.0 (1835) |

58.0 (5910) |

6000 | 0.042 | 13.6 | RK-100 | 2.5(25.6) |

| 3E-08 | 10 | 5 | 150 | 50 | 25.0 (2530) |

80.0 (8150) |

5000 | 0.14 | 26.5 | RK-125 | 2.2(22.5) |

| 3E-10 | 10 | 5 | 190 | 60 | 35.0 (3570) |

100.0 (10200) |

3600 | 0.31 | 39.5 |

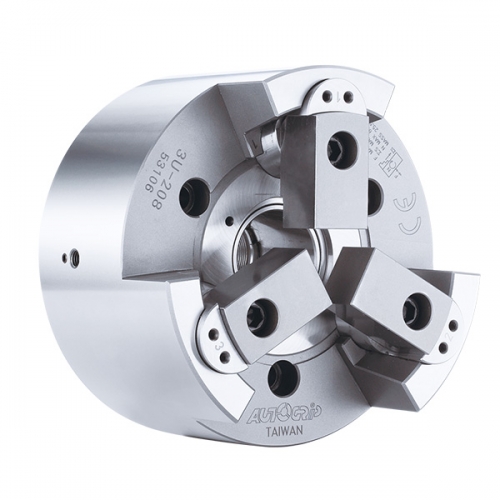

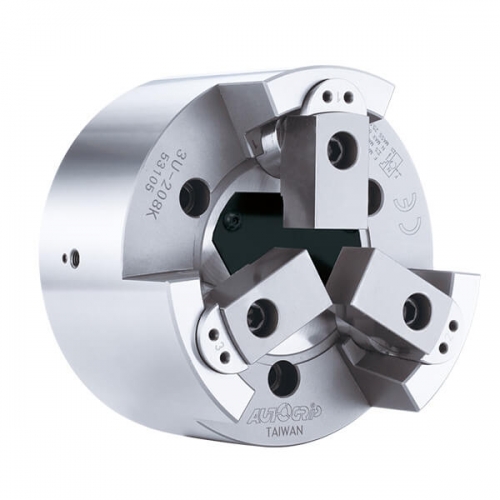

3U

| Model | Plunger stroke (mm) | Jaw stroke (Dia.)(mm) | Chucking Dia. max.(mm) | Chucking Dia. min.(mm) | Max. D.B. pull kN(kgf) | Max. clamping force kN(kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

3U-203

|

4 | 2 | 42 | 14 | 5.8(590) | 16.7(1700) | 10000 | 0.001 | 1.8 | RK-75(N) | 1.6(16) |

|

3U-204

|

6 | 3 | 60 | 10 | 10.0(1020) | 28.4(2900) | 8000 | 0.005 | 3.9 | RK-75(N) | 2.7(27) |

|

3U-205

|

6 | 3 | 84 | 15 | 13.9(1420) | 39.7(4050) | 8000 | 0.012 | 6.8 | RK-100(N) | 2.0(20) |

|

3U-206

|

10 | 5 | 105 | 24 | 17.9(1830) | 57.8(5900) | 7000 | 0.055 | 14.7 | RK-100(N) | 2.6(26) |

|

3U-208

|

12 | 6 | 132 | 25 | 25.0(2550) | 80.0(8150) | 6000 | 0.14 | 25.5 | RK-125(N) | 2.2(22) |

|

3U-210

|

10 | 5 | 163 | 34 | 31.0(3160) | 100.0(10100) | 4500 | 0.36 | 43.5 | RK-125(N) | 3.1(31) |

|

3U-212

|

10 | 5 | 210 | 81 | 35.0(3570) | 100.0(10100) |

3U-K

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. max. (mm) | Chucking Dia. min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1(r.p.m.) | I kg‧m2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

3U-205K

|

6 | 3 | 84 | 15 | 13.9(1420) | 39.7(4050) | 8000 | 0.018 | 6.8 | RL-100, RL-A100N |

2.0(20) |

|

3U-206K

|

10 | 5 | 105 | 24 | 17.9(1830) | 57.8(5900) | 7000 | 0.055 | 14.9 | RL-100, RL-A100N |

2.5(25) |

|

3U-208K

|

12 | 6 | 132 | 25 | 25.0(2550) | 80.0(8150) | 6000 | 0.14 | 25.8 | RL-125, RL-A125N |

2.2(22) |

|

3U-210K

|

10 | 5 | 163 | 34 | 31.0(3160) | 100(10100) | 4500 | 0.36 | 44 | RL-125, RL-A125N |

3.1(31) |

|

3U-212K

|

10 | 5 | 210 | 81 | 35.0(3570) | 100(10100) |

2D

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Weight (kg) | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2D-06 | 10 | 7.2 | 165 | 22 | 10.0 (1020) |

16.7 (1700) |

3500 | 0.045 | 12 | RK-100 | 1.4(14.3) |

| 2D-08 | 10 | 7.2 | 210 | 28 | 16.7 (1700) |

30.0 (3060) |

3500 | 0.13 | 23 | RK-125 | 1.5(15) |

| 2D-10 | 15 | 10.8 | 254 | 35 | 23.3 (2379) |

40.0 (4079) |

2500 | 0.34 | 43 |

3D

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Weight (kg) | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3D-04 | 7 | 5 | 110 | 13 | 6.0 (612) |

10.5 (1070) |

3500 | 0.007 | 4.5 | RK-75 | 1.6(16.5) |

| 3D-05 | 7 | 5 | 135 | 21 | 10.0 (1020) |

17.0 (1730) |

3500 | 0.018 | 7.9 | RK-75 | 2.7(27.5) |

| 3D-06 | 10 | 7.2 | 165 | 22 | 15.0 (1530) |

25.0 (2550) |

3500 | 0.051 | 15 | RK-100 | 2.1(21.4) |

| 3D-08 | 10 | 7.2 | 210 | 28 | 25.0 (2550) |

45.0 (4590) |

3000 | 0.15 | 26 | RK-125 | 2.2(22.5) |

| 3D-10 | 15 | 10.8 | 254 | 35 | 35.0 (3569) |

60.0 (6118) |

2500 | 0.37 | 46 |

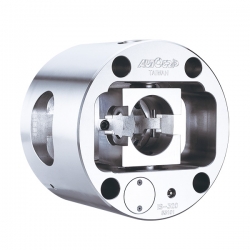

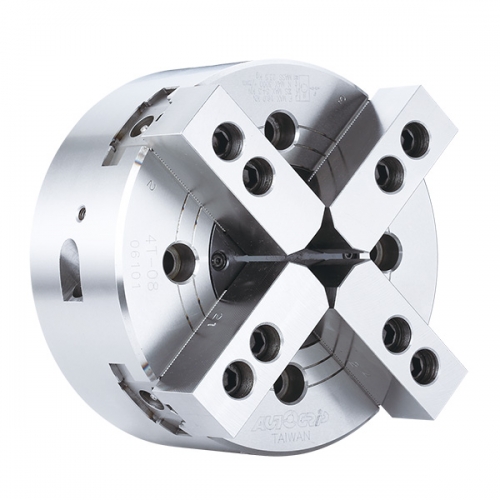

4T

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Range Max. (mm) | Chucking Range Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4T-08 | 17 | 13.6 | 210 | 24 | 16.0 (1630) |

54.3 (5540) |

3000 | 0.15 | 23.2 | RD-120(N) | 1.7(17) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4T-10 | 20 | <

| Model | Index Angle Deg | Jaw stroke (mm) | Chucking Area Dia. Max.(mm) | Chucking Area Dia. Max.(mm) | Max. pressure MPa (kgf/cm2) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | ROTATING JOINT | Main Spindle Bore(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| IS-254 | 4x90゜ | 20 | 65 | 160 | 45 | 19.5 (1990) |

2400 | 0.41 | 41.0 | IS-315 | 86+0.1 |

| IS-275 | 4x90゜ | 20 | 80 | 220 | 45 | 25.4 (2590) |

2100 | 0.61 | 52.0 | IS-315 | 86+0.1 |

| IS-315 | 4x90゜ | 20 | 100 | 230 | 45 | 25.0 (2550) |

1800 | 1.13 | 76.0 | IS-315 | 86+0.1 |

* Index Angle 8x45° or Specific Angle, Please contact AUTOGRIP for more detailed information.Thanks.

2J

| Model | Rotating stroke (mm) | Claming stroke (mm) | Jaw's compensation (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2J-05 | 12 | 8 | 2 | 53 | 25 | 5.0 (510) |

4.0 (408) |

4000 | 0.015 | 9 | RK-100 OR RK-100(N) |

0.7(7) |

| 2J-06 | 12 | 8 | 2 | 79 | 55 | 6.0 (612) |

5.0 (510) |

4000 | 0.035 | 9.8 | RK-100 OR RK-100(N) |

0.8(8) |

| 2J-08 | 12 | 8 | 2 | 106 | 75 | 12.0 (1224) |

11.0 (1122) |

3500 | 0.12 | 20.3 | RK-100 OR RK-100(N) |

1.7(17) |

| 2J-10 | 12 | 8 | 2.5 | 150 | 119 | 12.0 (1224) |

11.0 (1122) |

3500 | 0.28 | 30.7 | RK-100 OR RK-100(N) |

1.7(17) |

| 2J-12 | 12 | 8 | 2.5 | 200 | 169 | 12.0 (1224) |

11.0 (1122) |

3000 |

3J

| Model | Rotating stroke (mm) | Claming stroke (mm) | Jaw's compensation (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3J-05 | 12 | 8 | 2 | 53 | 25 | 7.5 (765) |

6.0 (612) |

4000 | 0.02 | 11.0 | RK-100 OR RK-100(N) |

1.0(10) |

| 3J-06 | 12 | 8 | 2 | 79 | 55 | 9.0 (918) |

7.5 (765) |

4000 | 0.04 | 12.0 | RK-100 OR RK-100(N) |

1.2(12) |

| 3J-08 | 12 | 8 | 2 | 106 | 75 | 18.0 (1835) |

16.5 (1680) |

3500 | 0.13 | 23.0 | RK-100 OR RK-100(N) |

2.5(25) |

| 3J-10 | 12 | 8 | 2.5 | 150 | 119 | 18.0 (1835) |

16.5 (1680) |

3500 | 0.3 | 33.0 | RK-100 OR RK-100(N) |

2.5(25) |

| 3J-12 | 12 | 8 | 2.5 | 200 | 169 | 18.0 (1835) |

16.5 (1680) |

3000 |

3R

| Model | Plunger stroke (mm) | Jaw stroke (Dia.)(mm) | Chucking Dia. max.(mm) | Chucking Dia. min.(mm) | Max. D.B. pull kN(kgf) | Max. clamping force kN(kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Compensation (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3R-08 | 20 | 8 | 65 | 18 | 19.6 (2000) | 53.0 (5404) | 2800 | 0.15 | 27 | RK-100(N) | 2 |

| 3R-10 | 25 | 10 | 90 | 22 | 29.4 (3000) | 67.7 (6901) |

3W

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chuckin Dia. OD Min.~Max. (mm) | Chucking Dia. ID Min.~Max. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. |

|---|---|---|---|---|---|---|---|---|---|---|

| 3W-08 | 14.4 | 9.8 | 16~150 | 76~203 | 25.0 (2550) |

85.0 (8670) |

3700 | 0.12 | 23 | RK-100(N) |

| 3W-10 | 17.5 | 12.5 | 50~205 | 85~235 | 35.3 (3600) |

105.9 (10800) |

2500 | 0.37 | 48.6 | RK-125(N) |

| 3W-12 | 17.5 | 12.5 | 63~240 | 127~305 | 35.3 (3600) |

105.9 (10800) |

2400 | 0.73 | 65 | RK-125(N) |

| 3W-15 | 22.5 | 15.9 | 76~317 | 165~381 | 56 (5600) |

168.2 (16800) |

2000 | 1.81 | 97 |

3W-C

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chuckin Dia. OD Min.~Max. (mm) | Chucking Dia. ID Min.~Max. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Compensation (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3W-C08 | 14.4 | 9.8 | 16~150 | 76~203 | 25.0 (2550) |

85.0 (8670) |

3700 | 0.12 | 23 | RK-100(N) | 2 |

| 3W-C10 | 17.5 | 12.5 | 50~205 | 85~235 | 35.3 (3600) |

105.9 (10800) |

2500 | 0.37 | 48.6 | RK-125(N) | 2 |

| 3W-C12 | 17.5 | 12.5 | 63~240 | 127~305 | 35.3 (3600) |

105.9 (10800) |

2400 | 0.73 | 65 | RK-125(N) | 2 |

| 3W-C15 | 22.5 | 15.9 | 76~317 | 165~381 | 56 (5600) |

168.2 (16800) |

2000 | 1.81 | 97 |

3E

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3E-05 | 6 | 3 | 83 | 29 | 13.0 (1325) |

42.0 (4280) |

7000 | 0.018 | 7.5 | RK-100 | 1.8(18.5) |

| 3E-06 | 10 | 5 | 110 | 44 | 18.0 (1835) |

58.0 (5910) |

6000 | 0.042 | 13.6 | RK-100 | 2.5(25.6) |

| 3E-08 | 10 | 5 | 150 | 50 | 25.0 (2530) |

80.0 (8150) |

5000 | 0.14 | 26.5 | RK-125 | 2.2(22.5) |

| 3E-10 | 10 | 5 | 190 | 60 | 35.0 (3570) |

100.0 (10200) |

3600 | 0.31 | 39.5 |

3U

| Model | Plunger stroke (mm) | Jaw stroke (Dia.)(mm) | Chucking Dia. max.(mm) | Chucking Dia. min.(mm) | Max. D.B. pull kN(kgf) | Max. clamping force kN(kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3U-203 | 4 | 2 | 42 | 14 | 5.8(590) | 16.7(1700) | 10000 | 0.001 | 1.8 | RK-75(N) | 1.6(16) |

| 3U-204 | 6 | 3 | 60 | 10 | 10.0(1020) | 28.4(2900) | 8000 | 0.005 | 3.9 | RK-75(N) | 2.7(27) |

| 3U-205 | 6 | 3 | 84 | 15 | 13.9(1420) | 39.7(4050) | 8000 | 0.012 | 6.8 | RK-100(N) | 2.0(20) |

| 3U-206 | 10 | 5 | 105 | 24 | 17.9(1830) | 57.8(5900) | 7000 | 0.055 | 14.7 | RK-100(N) | 2.6(26) |

| 3U-208 | 12 | 6 | 132 | 25 | 25.0(2550) | 80.0(8150) | 6000 | 0.14 | 25.5 | RK-125(N) | 2.2(22) |

| 3U-210 | 10 | 5 | 163 | 34 | 31.0(3160) | 100.0(10100) | 4500 | 0.36 | 43.5 | RK-125(N) | 3.1(31) |

| 3U-212 | 10 | 5 | 210 | 81 | 35.0(3570) | 100.0(10100) |

3U-K

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. max. (mm) | Chucking Dia. min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1(r.p.m.) | I kg‧m2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3U-205K | 6 | 3 | 84 | 15 | 13.9(1420) | 39.7(4050) | 8000 | 0.018 | 6.8 | RL-100, RL-A100N |

2.0(20) |

| 3U-206K | 10 | 5 | 105 | 24 | 17.9(1830) | 57.8(5900) | 7000 | 0.055 | 14.9 | RL-100, RL-A100N |

2.5(25) |

| 3U-208K | 12 | 6 | 132 | 25 | 25.0(2550) | 80.0(8150) | 6000 | 0.14 | 25.8 | RL-125, RL-A125N |

2.2(22) |

| 3U-210K | 10 | 5 | 163 | 34 | 31.0(3160) | 100(10100) | 4500 | 0.36 | 44 | RL-125, RL-A125N |

3.1(31) |

| 3U-212K | 10 | 5 | 210 | 81 | 35.0(3570) | 100(10100) |

2D

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Weight (kg) | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2D-06 | 10 | 7.2 | 165 | 22 | 10.0 (1020) |

16.7 (1700) |

3500 | 0.045 | 12 | RK-100 | 1.4(14.3) |

| 2D-08 | 10 | 7.2 | 210 | 28 | 16.7 (1700) |

30.0 (3060) |

3500 | 0.13 | 23 | RK-125 | 1.5(15) |

| 2D-10 | 15 | 10.8 | 254 | 35 | 23.3 (2379) |

40.0 (4079) |

2500 | 0.34 | 43 |

3D

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Weight (kg) | Max. pressure MPa (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3D-04 | 7 | 5 | 110 | 13 | 6.0 (612) |

10.5 (1070) |

3500 | 0.007 | 4.5 | RK-75 | 1.6(16.5) |

| 3D-05 | 7 | 5 | 135 | 21 | 10.0 (1020) |

17.0 (1730) |

3500 | 0.018 | 7.9 | RK-75 | 2.7(27.5) |

| 3D-06 | 10 | 7.2 | 165 | 22 | 15.0 (1530) |

25.0 (2550) |

3500 | 0.051 | 15 | RK-100 | 2.1(21.4) |

| 3D-08 | 10 | 7.2 | 210 | 28 | 25.0 (2550) |

45.0 (4590) |

3000 | 0.15 | 26 | RK-125 | 2.2(22.5) |

| 3D-10 | 15 | 10.8 | 254 | 35 | 35.0 (3569) |

60.0 (6118) |

2500 | 0.37 | 46 |

4T

| Model | Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Range Max. (mm) | Chucking Range Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4T-08 | 17 | 13.6 | 210 | 24 | 16.0 (1630) |

54.3 (5540) |

3000 | 0.15 | 23.2 | RD-120(N) | 1.7(17) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4T-10 | 20 | 16 | 254 | 50 | 21.6 (2200) |

79.4 (8100) |

2100 | 0.35 | 44.3 | RD-125(N) | 2.2(22) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4T-12 | 20 | 16 | 304 | 50 | 21.6 (2200) |

79.4 (8100) |

1500 | 0.66 | 57.6 | RD-125(N) | 2.2(22) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4T-15 | 25 | 19.6 | 381 | 60 | 27.2 (2780) |

105.3 (1075 IS

* Index Angle 8x45° or Specific Angle, Please contact AUTOGRIP for more detailed information.Thanks. 2J

3J

3R

3W

3W-C

3E

3U

3U-K

2D

3D

4T

|