Product Detail :

RAP

MP4

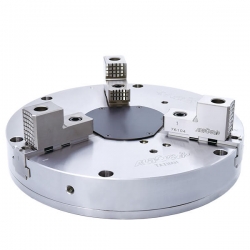

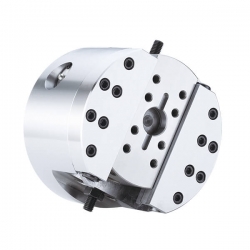

INTEGRATED STATIONARY CHUCKS(SP、SD、SU、SE)

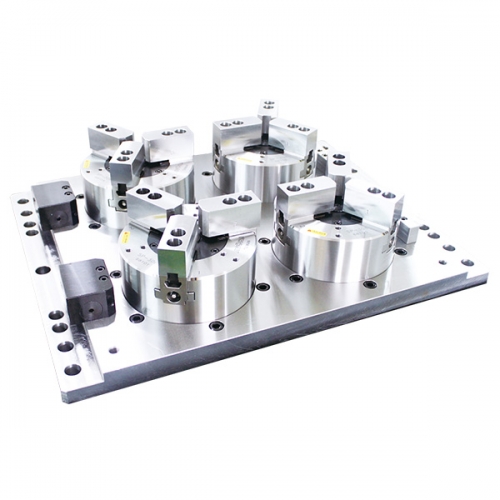

SCB

SE

SU

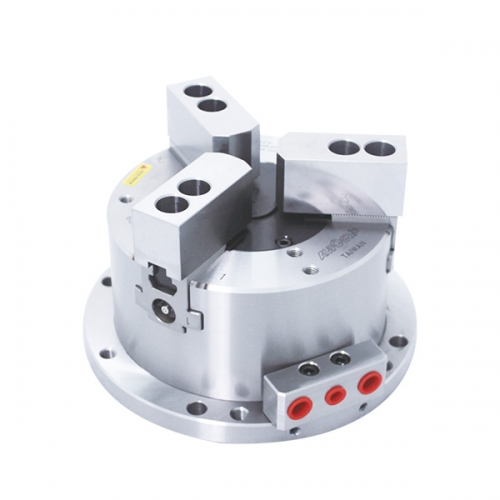

SD

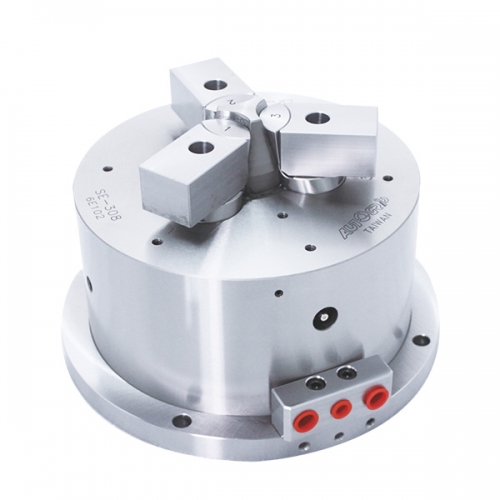

SP-3

SP-2

VP

VH

RAP

MP4

INTEGRATED STATIONARY CHUCKS(SP、SD、SU、SE)

SCB

SE

SU

SD

SP-3

SP-2

VP

VH

RAP

MP4

INTEGRATED STATIONARY CHUCKS(SP、SD、SU、SE)

SCB

SE

SU

SD

SP-3

SP-2

VP

VH

RAP

MP4

INTEGRATED STATIONARY CHUCKS(SP、SD、SU、SE)

SCB

SE

SU

SD

SP-3

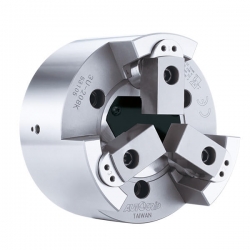

SP-2

VP

.jpg)