PAGE VIEW : 11,884

Product Information :

Name :

SYIC Category :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

Sub - Category :

- รับจัดหาสินค้าอุตสาหกรรมและอะไหล่ทุกชนิด

Brand :

SYIC Product Type :

- สินค้า, ผลิตภัณฑ์

Short Description :

SYIC syic holder SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC SYIC Product Detail :

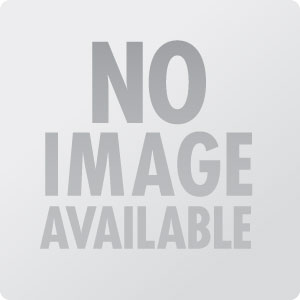

BT/MLD MULTI-LOCK MILLING CHUCK

- There is a special design for the slots of internal hole. It prevents the cutting tools from slipping and increases the clamping power.

- The body of the tool holder is thick, so it has good clamping power. It adopts the needle bearing design to prevent the slipping. The operation is convenient and easy.

- after locking the cutting tool (The tolerance of the cutting tool must be less than h6), it is more contacted with the flange while locking the clamping nut and tool holder. It can prevent the bearing cage from deformation easily. Also, rigidity and dust-proof function is improved.

- Superior right angle: It provides perfect processing surface during the process on the machine table.

- High stability of the precision and easy for combination. There won’t be a situation of vibration during the high speed processing or big cutting depth.

- Good clamping power. The clamping power of MLD32 type is around 1000 N-m.

- Run-out: Within 0.001~0.005mm.

- Concentricity: 0.02mm.

- The pre-balance can reach G6.3 8,000RPM, with an inspection report. The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

- When using MLD sealed cap, the coolant fluid discharges from the cutting tool.It's good for heat dissipation and metal chips removal.

- The design of coolant grooves improves the cooling and metal chips removal capability.

| MODEL NO. | TYPE | L | l1 | T | d1 | d2 | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|

| SYIC - 15900G | BT30 x MLD12 - 65 | 113.4 | 65 | M12 x 1.75P | 12 | 42 | 1 |

| SYIC - 15901G | BT30 x MLD16 - 75 | 123.4 | 75 | M12 x 1.75P | 16 | 48 | 1.2 |

| SYIC - 15902G | BT30 x MLD20 - 80 | 128.4 | 80 | M12 x 1.75P | 20 | 56.5 | 1.9 |

| SYIC - 15904G | BT30 x MLD20 - 90 | 138.4 | 90 | M16 x 2.0P | 20 | 56.5 | 2 |

| SYIC - 15908G | BT30 x MLD25 - 90 | 138.4 | 90 | M16 x 2.0P | 25 | 60 | 1.8 |

| SYIC - 15910G | BT40 x MLD12 - 75 | 140.4 | 75 | M12 x 1.75P | 12 | 42 | 1.5 |

| SYIC - 15910G-105 | BT40 x MLD12 - 105 | 170.4 | 105 | M12 x 1.75P | 12 | 42 | 2 |

| SYIC - 15910G-135 | BT40 x MLD12 - 135 | 200.4 | 135 | M12 x 1.75P | 12 | 42 | 2.1 |

| SYIC - 15911G | BT40 x MLD16 - 75 | 140.4 | 75 | M12 x 1.75P | 16 | 48 | 1.7 |

| SYIC - 15911G-105 | BT40 x MLD16 - 105 | 170.4 | 105 | M12 x 1.75P | 16 | 48 | 2.3 |

| SYIC - 15911G-135 | BT40 x MLD16 - 135 | 200.4 | 135 | M12 x 1.75P | 16 | 48 | 2.4 |

| SYIC - 15912G | BT40 x MLD20 - 80 | 145.4 | 80 | M16 x 2.0P | 20 | 56.5 | 2.3 |

| SYIC - 15914G | BT40 x MLD20 - 100 | 165.4 | 100 | M16 x 2.0P | 20 | 56.5 | 2.5 |

| SYIC - 15916G | BT40 x MLD20 - 135 | 200.4 | 135 | M16 x 2.0P | 20 | 56.5 | 2.8 |

| SYIC - 15918G | BT40 x MLD25 - 85 | 150.4 | 85 | M16 x 2.0P | 20 | 60 | 2.2 |

| SYIC - 15920G | BT40 x MLD25 - 100 | 165.4 | 100 | M16 x 2.0P | 20 | 60 | 2.4 |

| SYIC - 15922G | BT40 x MLD32 - 95 | 160.4 | 95 | M16 x 2.0P | 32 | 71 | 2.7 |

| SYIC - 15924G | BT40 x MLD32 - 105 | 170.4 | 105 | M16 x 2.0P | 32 | 71 | 2.7 |

| SYIC - 15926G | BT40 x MLD32 - 135 | 200.4 | 135 | M16 x 2.0P | 32 | 71 | 3 |

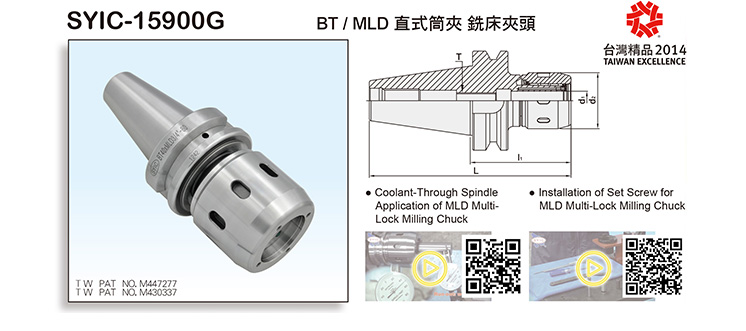

BT/EOC COLLET CHUCK

- Each collet chuck has been locked with a nut, but not including a spanner and collet.

- The draw bar thread can make pull studs locked precisely and easily, including 45°, 60°, and 90°.

- Suitable for heavy-duty cutting.

- Superior right angle: It provides perfect processing surface during the process on the machine table.

- The pre-balance can reach G6.3 10,000 rpm, without an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

- While ordering, Power Good Nuts could be purchased separately for combination.

| MODEL NO. | TYPE | L | l1 | l2 | d1 | T | SIZE RANGE | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| SYIC - 16001 | BT30 x EOC25 - 70 | 118.4 | 70 | 48 | 60 | M12 x 1.75P | 3.0 ~ 25 | 1 |

| SYIC - 16021 | BT40 x EOC25 - 70 | 135.4 | 70 | 40.5 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.38 |

| SYIC - 16023 | BT40 x EOC25 - 100 | 165.4 | 100 | 70.5 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.74 |

| SYIC - 16026 | BT40 x EOC25 - 120 | 185.4 | 120 | 74.5 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.74 |

| SYIC - 16027 | BT40 x EOC32 - 90 | 155.4 | 90 | 63 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2 |

| SYIC - 16029 | BT40 x EOC32 - 105 | 170.4 | 105 | 78 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2.2 |

| SYIC - 16031 | BT40 x EOC32 - 120 | 185.4 | 120 | 93 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2.45 |

| SYIC - 16041 | BT50 x EOC25 - 85 | 186.8 | 85 | 44.5 | 60 | M16 x 2.0P | 3.0 ~ 25 | 4.4 |

| SYIC - 16043 | BT50 x EOC25 - 100 | 201.8 | 100 | 59.5 | 60 | M16 x 2.0P | 3.0 ~ 25 | 4.8 |

| SYIC - 16046 | BT50 x EOC25 - 120 | 221.8 | 120 | 77 | 60 | M16 x 2.0P | 3.0 ~ 25 | 5.2 |

| SYIC - 16047 | BT50 x EOC32 - 90 | 191.8 | 90 | 44 | 72 | M24 x 2.0P | 4.0 ~ 32 | 4.6 |

| SYIC - 16049 | BT50 x EOC32 - 105 | 206.8 | 105 | 59 | 72 | M24 x 2.0P | 4.0 ~ 32 | 4.85 |

| SYIC - 16051 | BT50 x EOC32 - 120 | 221.8 | 120 | 74 | 72 | M24 x 2.0P | 4.0 ~ 32 | 5.35 |

BT/TG COLLET CHUCK

| d1 TEST BAR DIAMETER MIN. MAX. | L | CONCENTRICITY |  |

|

|---|---|---|---|---|

| 3 | 6 | 16 | 0.01 | |

| 6 | 10 | 25 | 0.01 | |

| 10 | 18 | 40 | 0.01 | |

| 18 | 24 | 50 | 0.01 | |

| 24 | 32 | 60 | 0.01 | |

- Every collet shipped out of the factory has been passed inspection.

- Standard testing table is in accordance with the cutting length and precise requirements of various sizes of end mills.

- Collet taper is 4.1751°, good concentricity and clamping capacity.

- Suitable for heavy-duty cutting.

- Particular square thread design enables good clamping capacity.

- The price includes a nut, but without any spanner and collets.

- While ordering, other Power Good Nuts could be purchased separately for combination.

- The pre-balance can reach G6.3 10,000 rpm, without an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

| MODEL NO. | TYPE - l1 | L | l2 | d1 | SIZE RANGE | t1 | T | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| SYIC - 16056 | BT30 x TG75 - 70 | 118.4 | 47 | 50 | 3.0 ~ 16 | M16 x 2.0P | TW 1-1/2" - 12 | 1.1 |

| SYIC - 16058 | BT30 x TG75 - 100 | 148.4 | 77 | 50 | 3.0 ~ 16 | M16 x 2.0P | TW 1-1/2" - 12 | 1.15 |

| SYIC - 16060 | BT30 x TG100 - 100 | 148.4 | 78 | 60 | 3.0 ~ 25 | - | TW 1-7/8" - 12 | 1.2 |

| SYIC - 16068 | BT40 x TG100 - 70 | 135.4 | 43 | 60 | 3.0 ~ 25 | M16 x 2.0P | TW 1-7/8" - 12 | 1.2 |

| SYIC - 16070 | BT40 x TG100 - 100 | 165.4 | 73 | 60 | 3.0 ~ 25 | M16 x 2.0P | TW 1-7/8" - 12 | 1.9 |

| SYIC - 16072 | BT40 x TG100 - 120 | 185.4 | 93 | 60 | 3.0 ~ 25 | M16 x 2.0P | TW 1-7/8" - 12 | 2.4 |

| SYIC - 16074 | BT40 x TG150 - 105 | 170.4 | 78 | 82 | 4.0 ~ 38 | M24 x 2.0P | TW 2-5/8" - 12 | 2.7 |

| SYIC - 16076 | BT40 x TG150 - 120 | 185.4 | 93 | 82 | 4.0 ~ 38 | M24 x 2.0P | TW 2-5/8" - 12 | 2.9 |

| SYIC - 16078 | BT40 x TG150 - 135 | 200.4 | 108 | 82 | 4.0 ~ 38 | M24 x 2.0P | TW 2-5/8" - 12 | 3.2 |

| SYIC - 16088 | BT50 x TG100 - 85 | 186.8 | 44 | 60 | 3.0 ~ 25 | M24 x 2.0P | TW 1-7/8" - 12 | 3.4 |

| SYIC - 16090 | BT50 x TG100 - 100 | 201.8 | 57 | 60 | 3.0 ~ 25 | M24 x 2.0P | TW 1-7/8" - 12 | 4.4 |

| SYIC - 16092 | BT50 x TG100 - 120 | 221.8 | 77 | 60 | 3.0 ~ 25 | M24 x 2.0P | TW 1-7/8" - 12 | 5.1 |

| SYIC - 16094 | BT50 x TG150 - 90 | 191.8 | 50 | 82 | 4.0 ~ 38 | M24 x 2.0P | TW 2-5/8" - 12 | 5.7 |

| SYIC - 16096 | BT50 x TG150 - 105 | 206.8 | 64 | 82 | 4.0 ~ 38 | M24 x 2.0P | TW 2-5/8" - 12 | 6.1 |

| SYIC - 16098 | BT50 x TG150 - 120 | 221.8 | 79 | 82 | 4.0 ~ 38 | M24 x 2.0P | TW 2-5/8" - 12 | 6.5 |

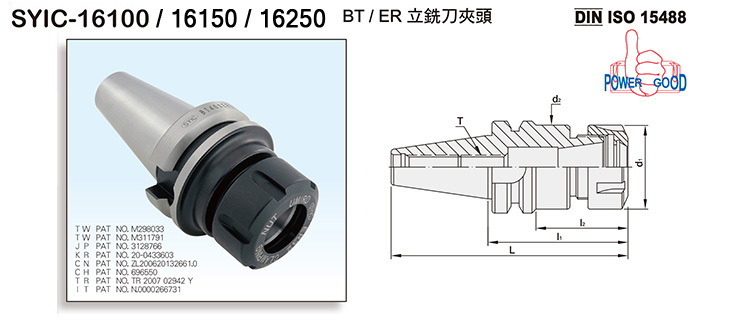

BT/ER COLLET CHUCK

SYIC-16100

- Thread with precise grinding.

- The pre-balance can reach G6.3 10,000 rpm, without an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

| MODEL NO. | TYPE - l1 | L | l2 | d1 | d2 | T | SIZE RANGE | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| SYIC - 16101 - 50 | BT30 x ER16A - 50 | 98.4 | 27 | 28 | 25.1 | M10 x 1.5P | 1.0 ~ 10 | 0.45 |

| SYIC - 16101 | BT30 x ER16A - 70 | 118.4 | 40 | 28 | 28 | M10 x 1.5P | 1.0 ~ 10 | 0.55 |

| SYIC - 16102 | BT30 x ER16A - 60 | 108.4 | 35 | 28 | 28 | M10 x 1.5P | 1.0 ~ 10 | 0.6 |

| SYIC - 16104 | BT30 x ER16A - 100 | 148.4 | 70 | 28 | 28 | M10 x 1.5P | 1.0 ~ 10 | 0.7 |

| SYIC - 16105 | BT30 x ER16A - 120 | 168.4 | 93 | 28 | 28 | M10 x 1.5P | 1.0 ~ 10 | 0.78 |

| SYIC - 16106 - 50 | BT30 x ER20A - 50 | 98.4 | 28 | 34 | - | M12 x 1.75P | 1.0 ~ 13 | 0.48 |

| SYIC - 16106 | BT30 x ER20A - 70 | 118.4 | 45 | 34 | 34 | M12 x 1.75P | 1.0 ~ 13 | 0.62 |

| SYIC - 16107 | BT30 x ER20A - 135 | 183.4 | 110 | 34 | 34 | M12 x 1.75P | 1.0 ~ 13 | 1.1 |

| SYIC - 16109 | BT30 x ER25 - 70 | 118.4 | 46 | 42 | 42 | M16 x 2.0P | 1.0 ~ 16 | 0.7 |

| SYIC - 16111 | BT30 x ER25 - 135 | 183.4 | 111 | 42 | 42 | M16 x 2.0P | 1.0 ~ 16 | 1.45 |

| SYIC - 16113 | BT30 x ER32 - 70 | 118.4 | 48 | 50 | 45 | M16 x 2.0P | 2.0 ~ 20 | 0.7 |

| SYIC - 16114 | BT30 x ER32 - 100 | 148.4 | 78 | 50 | 45 | M16 x 2.0P | 2.0 ~ 20 | 1 |

| SYIC - 16115 | BT30 x ER40 - 80 | 128.4 | 58 | 63 | 53 | M16 x 2.0P | 3.0 ~ 26 | 1.1 |

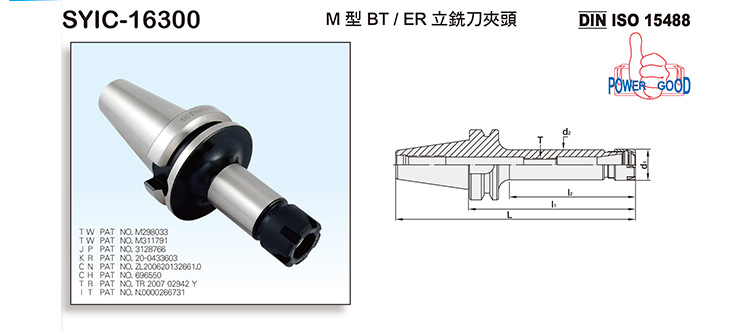

BT/PNER COLLET CHUCK

- The pre-balance can reach G6.3 10,000 rpm, without an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

| MODEL NO. | TYPE - l1 | L | l2 | d1 | d2 | T | SIZE RANGE | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| SYIC - 16302 | BT30 x ER11M - 70 | 118.4 | 40 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 0.5 |

| SYIC - 16304 | BT30 x ER11M - 100 | 148.4 | 70 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 0.6 |

| SYIC - 16306 | BT30 x ER11M - 120 | 168.4 | 88 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 0.7 |

| SYIC - 16308 | BT30 x ER16M - 70 | 118.4 | 43 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 0.55 |

| SYIC - 16310 | BT30 x ER16M - 100 | 148.4 | 68 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 0.56 |

| SYIC - 16312 | BT30 x ER16M - 120 | 168.4 | 88 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 0.75 |

| SYIC - 16313 | BT30 x ER20M - 70 | 118.4 | 45 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 0.65 |

| SYIC - 16314 | BT30 x ER20M - 100 | 148.4 | 71 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 0.7 |

| SYIC - 16316 | BT30 x ER20M - 120 | 168.4 | 91 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 0.8 |

| SYIC - 16318 | BT30 x ER20M - 150 | 198.4 | 121 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 1 |

| SYIC - 16321 | BT40 x ER11M - 70 | 135.4 | 33 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 1.1 |

| SYIC - 16322 | BT40 x ER11M - 100 | 165.4 | 63 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 1.1 |

| SYIC - 16323 | BT40 x ER11M - 125 | 190.4 | 88 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 1.12 |

| SYIC - 16324 | BT40 x ER11M - 150 | 215.4 | 113 | 16 | 15 | M6 x 1.0P | 1.0 ~ 7 | 1.2 |

| SYIC - 16325 | BT40 x ER16M - 70 | 135.4 | 38 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 1.1 |

| SYIC - 16326 | BT40 x ER16M - 100 | 165.4 | 63 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 1.16 |

| SYIC - 16327 | BT40 x ER16M - 125 | 190.4 | 88 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 1.2 |

| SYIC - 16328 | BT40 x ER16M - 150 | 215.4 | 113 | 22 | 21 | M10 x 1.5P | 1.0 ~ 10 | 1.3 |

| SYIC - 16329 | BT40 x ER20M - 70 | 135.4 | 38 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 1.2 |

| SYIC - 16330 | BT40 x ER20M - 100 | 165.4 | 63 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 1.25 |

| SYIC - 16331 | BT40 x ER20M - 125 | 190.4 | 88 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 1.3 |

| SYIC - 16332 | BT40 x ER20M - 150 | 215.4 | 113 | 28 | 27 | M12 x 1.75P | 1.0 ~ 13 | 1.45 |

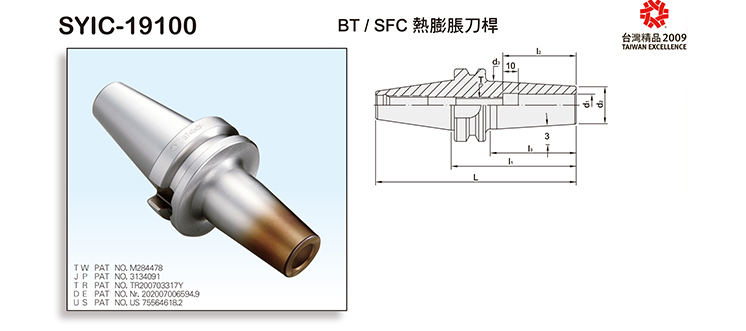

BT/SFC Shrink Fit Chuck

- High rigidity.

- T.I.R.: within 5 μ.

- Slim design.

- Easy operation.

- Every tool holder reaches the standard of G2.5 25,000 rpm, with an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

- For tool shank with h6 tolerance, such as Form HA to DIN6535 and Form A to DIN 1835-1, except that the internal hole of Shrink Fit Chuck is less than 6mm.

| MODEL NO. | TYPE d1 - l1 | L | l2 | l3 | d2 | d3 | T | TORQUE N.m min | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|

| SYIC - 19102 | BT30 x SFC4 - 80 | 128.4 | 20 | 48 | 10 | 15 | M6 x 1.0P | 18 | 0.42 |

| SYIC - 19104 | BT30 x SFC5 - 80 | 128.4 | 20 | 53 | 16 | 19 | M5 x 0.8P | 18 | 0.54 |

| SYIC - 19106 | BT30 x SFC6 - 80 | 128.4 | 36 | 53 | 21 | 26 | M6 x 1.0P | 18 | 0.64 |

| SYIC - 19108 | BT30 x SFC8 - 80 | 128.4 | 36 | 53 | 21 | 26 | M8 x 1.25P | 35 | 0.56 |

| SYIC - 19110 | BT30 x SFC10 - 80 | 128.4 | 42 | 53 | 24 | 29 | M10 x 1.5P | 65 | 0.66 |

| SYIC - 19112 | BT30 x SFC12 - 80 | 128.4 | 47 | 53 | 24 | 29 | M10 x 1.5P | 110 | 0.66 |

| SYIC - 19114 | BT30 x SFC14 - 80 | 128.4 | 47 | 46 | 24 | 32 | M12 x 1.75P | 150 | 0.58 |

| SYIC - 19116 | BT30 x SFC16 - 80 | 128.4 | 50 | 55 | 27 | 32 | M12 x 1.75P | 200 | 0.60 |

| SYIC - 19118 | BT30 x SFC18 - 90 | 138.4 | 50 | 66 | 33 | 38 | M16 x 2.0P | 250 | 0.80 |

| SYIC - 19120 | BT30 x SFC20 - 90 | 138.4 | 52 | 66 | 33 | 38 | M20 x 2.0P | 320 | 0.76 |

| SYIC - 19122 | BT30 x SFC25 - 100 | 148.4 | 58 | 78 | 44 | 49 | M6 x 1.0P | 500 | 1.17 |

| SYIC - 19132 | BT40 x SFC4 - 90 | 155.4 | 20 | 53 | 10 | 15.6 | M6 x 1.0P | 18 | 1.01 |

| SYIC - 19134 | BT40 x SFC5 - 90 | 155.4 | 20 | 58 | 16 | 21 | M5 x 0.8P | 18 | 1.07 |

| SYIC - 19136 | BT40 x SFC6 - 90 | 155.4 | 36 | 58 | 21 | 26 | M6 x 1.0P | 18 | 1.15 |

| SYIC - 19138 | BT40 x SFC8 - 90 | 155.4 | 36 | 58 | 21 | 26 | M8 x 1.25P | 35 | 1.15 |

| SYIC - 19140 | BT40 x SFC10 - 90 | 155.4 | 42 | 58 | 24 | 29 | M10 x 1.5P | 65 | 1.20 |

| SYIC - 19142 | BT40 x SFC12 - 90 | 155.4 | 47 | 58 | 24 | 29 | M10 x 1.5P | 110 | 1.19 |

| SYIC - 19144 | BT40 x SFC14 - 90 | 155.4 | 47 | 58 | 27 | 32 | M12 x 1.75P | 150 | 1.24 |

| SYIC - 19146 | BT40 x SFC16 - 90 | 155.4 | 50 | 58 | 27 | 32 | M12 x 1.75P | 200 | 1.21 |

| SYIC - 19148 | BT40 x SFC18 - 100 | 165.4 | 50 | 68 | 33 | 38 | M16 x 2.0P | 250 | 1.42 |

| SYIC - 19186 | BT40 x SFC19 - 90 | 155.4 | 60 | 58 | 33 | 38 | M16 x 2.0P | 250 | 1.40 |

| SYIC - 19150 | BT40 x SFC20 - 100 | 165.4 | 52 | 68 | 33 | 38 | M20 x 2.0P | 320 | 1.38 |

| SYIC - 19188 | BT40 x SFC24 - 90 | 155.4 | 72 | 61 | 44 | 49 | M20 x 2.0P | 500 | 1.36 |

| SYIC - 19152 | BT40 x SFC25 - 100 | 165.4 | 58 | 71 | 44 | 49 | M20 x 2.0P | 500 | 1.66 |

| SYIC - 19154 | BT40 x SFC32 - 100 | 165.4 | 58 | 71 | 44 | 49 | M20 x 2.0P | 550 | 1.52 |

| SYIC - 19162 | BT50 x SFC4 - 100 | 201.8 | 20 | 52 | 10 | 15.5 | M6 x 1.0P | 18 | 3.86 |

| SYIC - 19164 | BT50 x SFC5 - 100 | 201.8 | 20 | 57 | 16 | 21 | M5 x 0.8P | 18 | 3.86 |

| SYIC - 19166 | BT50 x SFC6 - 100 | 201.8 | 36 | 57 | 21 | 26 | M6 x 1.0P | 18 | 3.92 |

| SYIC - 19168 | BT50 x SFC8 - 100 | 201.8 | 36 | 52 | 21 | 26 | M6 x 1.0P | 35 | 3.92 |

| SYIC - 19170 | BT50 x SFC10 - 100 | 201.8 | 42 | 58 | 24 | 29 | M8 x 1.25P | 65 | 3.90 |

| SYIC - 19172 | BT50 x SFC12 - 100 | 201.8 | 47 | 52 | 24 | 29 | M10 x 1.5P | 110 | 3.94 |

| SYIC - 19174 | BT50 x SFC14 - 100 | 201.8 | 47 | 57 | 27 | 32 | M10 x 1.5P | 150 | 4.02 |

| SYIC - 19176 | BT50 x SFC16 - 100 | 201.8 | 50 | 52 | 27 | 32 | M12 x 1.75P | 200 | 3.96 |

| SYIC - 19178 | BT50 x SFC18 - 110 | 211.8 | 50 | 62 | 33 | 38 | M12 x 1.75P | 250 | 4.18 |

| SYIC - 19180 | BT50 x SFC20 - 110 | 211.8 | 52 | 67 | 33 | 38 | M16 x 2.0P | 320 | 4.14 |

| SYIC - 19182 | BT50 x SFC25 - 110 | 211.8 | 58 | 67 | 44 | 49 | M20 x 2.0P | 500 | 4.46 |

| SYIC - 19184 | BT50 x SFC32 - 110 | 211.8 | 58 | 67 | 44 | 49 | M20 x 2.0P | 550 | 4.30 |

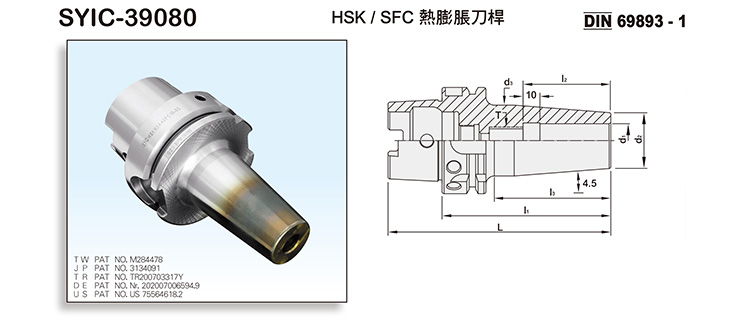

HSK/SFC Shrink Fit Chuck For Type A

- High rigidity.

- T.I.R.: within 5 μ.

- Slim design.

- Easy operation.

- Every tool holder reaches the standard of G2.5 25,000 rpm, with an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

- For tool shank with h6 tolerance, such as Form HA to DIN6535 and Form A to DIN 1835-1, except that the internal hole of Shrink Fit Chuck is less than 6mm.

| MODEL NO. | TYPE d1 - I1 | L | I2 | I3 | d2 | d3 | T | TORQUE N.m min | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|

| SYIC - 39082 | HSK40A x SFC3 - 80 | 100 | 18 | 55 | 9 | 17.7 | - | 18 | 0.25 |

| SYIC - 39084 | HSK40A x SFC4 - 80 | 100 | 20 | 55 | 10 | 18.7 | - | 18 | 0.26 |

| SYIC - 39086 | HSK40A x SFC5 - 80 | 100 | 20 | 55 | 16 | 22 | - | 18 | 0.33 |

| SYIC - 39088 | HSK40A x SFC6 - 80 | 100 | 36 | 57 | 21 | 27 | M5 x 0.8P | 18 | 0.41 |

| SYIC - 39090 | HSK40A x SFC8 - 80 | 100 | 36 | 57 | 21 | 27 | M6 x 1.0P | 35 | 0.40 |

| SYIC - 39092 | HSK40A x SFC10 - 85 | 105 | 42 | 64 | 24 | 32 | M8 x 1.25P | 65 | 0.49 |

| SYIC - 39094 | HSK40A x SFC12 - 90 | 110 | 47 | 69 | 24 | 32 | M10 x 1.5P | 110 | 0.50 |

| SYIC - 39096 | HSK40A x SFC14 - 90 | 110 | 47 | 69 | 27 | 34 | M10 x 1.5P | 150 | 0.56 |

| SYIC - 39098 | HSK40A x SFC16 - 90 | 110 | 47 | 69 | 27 | 34 | M12 x 1.75P | 200 | 0.53 |

| SYIC - 39100 | HSK50A x SFC3 - 80 | 105 | 18 | 49 | 9 | 16.7 | - | 18 | 0.43 |

| SYIC - 39102 | HSK50A x SFC4 - 80 | 105 | 20 | 49 | 10 | 17.7 | - | 18 | 0.44 |

| SYIC - 39104 | HSK50A x SFC5 - 80 | 105 | 20 | 49 | 16 | 22 | - | 18 | 0.50 |

| SYIC - 39106 | HSK50A x SFC6 - 80 | 105 | 36 | 49 | 21 | 27 | M5 x 0.8P | 18 | 0.58 |

| SYIC - 39108 | HSK50A x SFC8 - 80 | 105 | 36 | 49 | 21 | 27 | M6 x 1.0P | 35 | 0.57 |

| SYIC - 39110 | HSK50A x SFC10 - 85 | 110 | 42 | 54 | 24 | 32 | M8 x 1.25P | 65 | 0.65 |

| SYIC - 39112 | HSK50A x SFC12 - 90 | 115 | 47 | 59 | 24 | 32 | M10 x 1.5P | 110 | 0.66 |

| SYIC - 39114 | HSK50A x SFC14 - 90 | 115 | 47 | 59 | 24 | 32 | M10 x 1.5P | 150 | 0.65 |

| SYIC - 39116 | HSK50A x SFC16 - 95 | 120 | 50 | 64 | 27 | 34 | M12 x 1.75P | 200 | 0.72 |

| SYIC - 39118 | HSK50A x SFC18 - 95 | 120 | 52 | 67 | 33 | 42 | M12 x 1.75P | 250 | 0.89 |

| SYIC - 39120 | HSK50A x SFC20 - 100 | 125 | 52 | 73 | 33 | 42 | M16 x 2.0P | 320 | 0.90 |

| SYIC - 39122 | HSK50A x SFC25 - 115 | 140 | 47 | 88 | 44 | 53 | M20 x 2.0P | 550 | 1.39 |

Collets

Boring Heads

Angle Heads

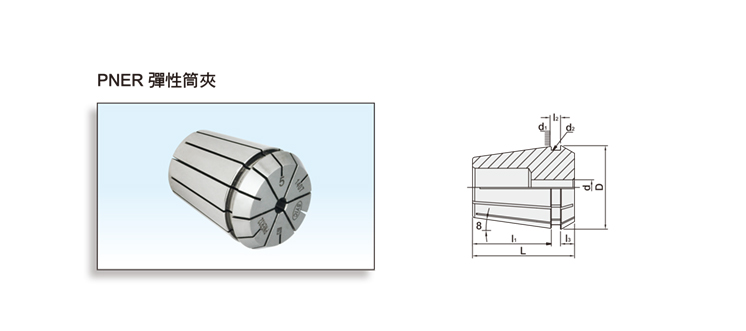

PNER COLLET

| MODEL NO. | TYPE | L | l1 | l2 | l3 | D | d1 | d2 | SIZE RANGE | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| SYIC-04216-PN | PNER16 | 27.5 | 20.8 | 3.4 | 4 | 16.8 | 16 | 13.8 | 3.0 - 10 | 0.03 |

| SYIC-04220-PN | PNER20 | 31.5 | 23.9 | 3.4 | 4.8 | 20.8 | 20 | 17.4 | 3.0 - 13 | 0.04 |

| SYIC-04225-PN | PNER25 | 34 | 25.9 | 3.6 | 5 | 25.8 | 25 | 21.9 | 3.0 - 16 | 0.06 |

| SYIC-04232-PN | PNER32 | 40 | 30.9 | 4.1 | 5.5 | 32.7 | 32 | 29.2 | 3.0 - 20 | 0.1 |

| SYIC-04240-PN | PNER40 | 46 | 34.5 | 4.5 | 7 | 40.85 | 40 | 36.2 | 6.0 - 26 | 0.25 |

METRIC

| PNER 16 | PNER 20 | PNER 25 | PNER 32 | PNER 40 | |||||

|---|---|---|---|---|---|---|---|---|---|

| MODEL NO. | SIZE | MODEL NO. | SIZE | MODEL NO. | SIZE | MODEL NO. | SIZE | MODEL NO. | SIZE |

| 04216-PN - 03 | 3 | 04220-PN - 03 | 3 | 04225-PN - 03 | 3 | 04232-PN - 03 | 3 | ||

| 04216-PN - 04 | 4 | 04220-PN - 04 | 4 | 04225-PN - 04 | 4 | 04232-PN - 04 | 4 | ||

| 04216-PN - 05 | 5 | 04220-PN - 05 | 5 | 04225-PN - 05 | 5 | 04232-PN - 05 | 5 | ||

| 04216-PN - 06 | 6 | 04220-PN - 06 | 6 | 04225-PN - 06 | 6 | 04232-PN - 06 | 6 | 04240-PN - 06 | 6 |

| 04216-PN - 07 | 7 | 04220-PN - 07 | 7 | 04225-PN - 07 | 7 | 04232-PN - 07 | 7 | 04240-PN - 07 | 7 |

| 04216-PN - 08 | 8 | 04220-PN - 08 | 8 | 04225-PN - 08 | 8 | 04232-PN - 08 | 8 | 04240-PN - 08 | 8 |

| 04216-PN - 09 | 9 | 04220-PN - 09 | 9 | 04225-PN - 09 | 9 | 04232-PN - 09 | 9 | 04240-PN - 09 | 9 |

| 04216-PN - 10 | 10 | 04220-PN - 10 | 10 | 04225-PN - 10 | 10 | 04232-PN - 10 | 10 | 04240-PN - 10 | 10 |

| 04220-PN - 11 | 11 | 04225-PN - 11 | 11 | 04232-PN - 11 | 11 | 04240-PN - 11 | 11 | ||

| 04220-PN - 12 | 12 | 04225-PN - 12 | 12 | 04232-PN - 12 | 12 | 04240-PN - 12 | 12 | ||

| 04220-PN - 13 | 13 | 04225-PN - 13 | 13 | 04232-PN - 13 | 13 | 04240-PN - 13 | 13 | ||

| 04225-PN - 14 | 14 | 04232-PN - 14 | 14 | 04240-PN - 14 | 14 | ||||

| 04225-PN - 15 | 15 | 04232-PN - 15 | 15 | 04240-PN - 15 | 15 | ||||

| 04225-PN - 16 | 16 | 04232-PN - 16 | 16 | 04240-PN - 16 | 16 | ||||

| 04232-PN - 17 | 17 | 04240-PN - 17 | 17 | ||||||

| 04232-PN - 18 | 18 | 04240-PN - 18 | 18 | ||||||

| 04232-PN - 19 | 19 | 04240-PN - 19 | 19 | ||||||

| 04232-PN - 20 | 20 | 04240-PN - 20 | 20 | ||||||

| 04240-PN - 21 | 21 | ||||||||

| 04240-PN - 22 | 22 | ||||||||

| 04240-PN - 23 | 23 | ||||||||

| 04240-PN - 24 | 24 | ||||||||

| 04240-PN - 25 | 25 | ||||||||

| 04240-PN - 26 | 26 | ||||||||

INCHES

| PNER 16 | PNER 20 | PNER 25 | PNER 32 | PNER 40 | |||||

|---|---|---|---|---|---|---|---|---|---|

| MODEL NO. | SIZE | MODEL NO. | SIZE | MODEL NO. | SIZE | MODEL NO. | SIZE | MODEL NO. | SIZE |

| 04216-PN-1/8 | 1/8 | 04220-PN-1/8 | 1/8 | 04225-PN-1/8 | 1/8 | 04232-PN-1/8 | 1/8 | ||

| 04216-PN-5/32 | 5/32 | 04220-PN-5/32 | 5/32 | 04225-PN-5/32 | 5/32 | 04232-PN-5/32 | 5/32 | ||

| 04216-PN-3/16 | 3/16 | 04220-PN-3/16 | 3/16 | 04225-PN-3/16 | 3/16 | 04232-PN-3/16 | 3/16 | ||

| 04216-PN-7/32 | 7/32 | 04220-PN-7/32 | 7/32 | 04225-PN-7/32 | 7/32 | 04232-PN-7/32 | 7/32 | ||

| 04216-PN-1/4 | 1/4 | 04220-PN-1/4 | 1/4 | 04225-PN-1/4 | 1/4 | 04232-PN-1/4 | 1/4 | 04240-PN-1/4 | 1/4 |

| 04216-PN-9/32 | 9/32 | 04220-PN-9/32 | 9/32 | 04225-PN-9/32 | 9/32 | 04232-PN-9/32 | 9/32 | 04240-PN-9/32 | 9/32 |

| 04216-PN-5/16 | 5/16 | 04220-PN-5/16 | 5/16 | 04225-PN-5/16 | 5/16 | 04232-PN-5/16 | 5/16 | 04240-PN-5/16 | 5/16 |

| 04216-PN-11/32 | 11/32 | 04220-PN-11/32 | 11/32 | 04225-PN-11/32 | 11/32 | 04232-PN-11/32 | 11/32 | 04240-PN-11/32 | 11/32 |

| 04216-PN-3/8 | 3/8 | 04220-PN-3/8 | 3/8 | 04225-PN-3/8 | 3/8 | 04232-PN-3/8 | 3/8 | 04240-PN-3/8 | 3/8 |

| 04216-PN-13/32 | 13/32 | 04220-PN-13/32 | 13/32 | 04225-PN-13/32 | 13/32 | 04232-PN-13/32 | 13/32 | 04240-PN-13/32 | 13/32 |

| 04220-PN-7/16 | 7/16 | 04225-PN-7/16 | 7/16 | 04232-PN-7/16 | 7/16 | 04240-PN-7/16 | 7/16 | ||

| 04220-PN-15/32 | 15/32 | 04225-PN-15/32 | 15/32 | 04232-PN-15/32 | 15/32 | 04240-PN-15/32 | 15/32 | ||

| 04220-PN-1/2 | 1/2 | 04225-PN-1/2 | 1/2 | 04232-PN-1/2 | 1/2 | 04240-PN-1/2 | 1/2 | ||

| 04225-PN-17/32 | 17/32 | 04232-PN-17/32 | 17/32 | 04240-PN-17/32 | 17/32 | ||||

| 04225-PN-9/16 | 9/16 | 04232-PN-9/16 | 9/16 | 04240-PN-9/16 | 9/16 | ||||

| 04225-PN-19/32 | 19/32 | 04232-PN-19/32 | 19/32 | 04240-PN-19/32 | 19/32 | ||||

| 04225-PN-5/8 | 5/8 | 04232-PN-5/8 | 5/8 | 04240-PN-5/8 | 5/8 | ||||

| 04225-PN-3/4 | 3/4 | 04232-PN-21/32 | 21/32 | 04240-PN-21/32 | 21/32 | ||||

| 04232-PN-11/16 | 11/16 | 04240-PN-11/16 | 11/16 | ||||||

| 04232-PN-23/32 | 23/32 | 04240-PN-23/32 | 23/32 | ||||||

| 04232-PN-3/4 | 3/4 | 04240-PN-3/4 | 3/4 | ||||||

| 04240-PN-25/32 | 25/32 | ||||||||

| 04240-PN-13/16 | 13/16 | ||||||||

| 04240-PN-27/32 | 27/32 | ||||||||

| 04240-PN-7/8 | 7/8 | ||||||||

| 04240-PN-29/32 | 29/32 | ||||||||

| 04240-PN-15/16 | 15/16 | ||||||||

| 04240-PN-31/32 | 31/32 | ||||||||

| 04240-PN-1 | 1 | ||||||||

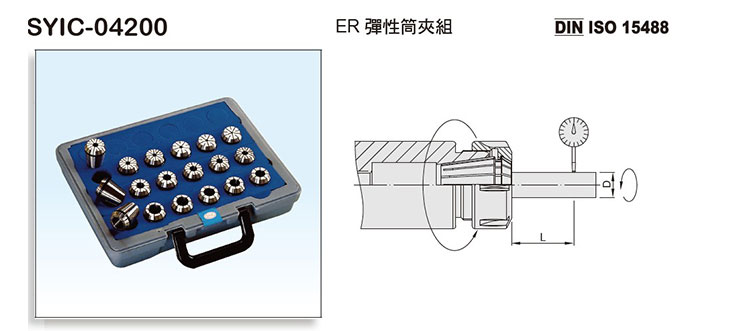

ER Collet Set

- Substitution for point 5 types is acceptable; price needs to be quoted additionally.

- ER8, ER11 and ER50 collets are packed with wooden boxes; ER16, ER20, ER25 , ER32 and ER40 with plastic boxes.

- Collets of special sizes could be ordered by request.

| L mm | D mm | CONCEN- TRICITY | ER- UP CLASS | ER-A CLASS |

|---|---|---|---|---|

| 6 | 1.0 - 1.4 | 0.015 | 0.005 | 0.01 |

| 10 | 1.5 - 2.9 | 0.015 | 0.005 | 0.01 |

| 16 | 3.0 - 5.9 | 0.015 | 0.005 | 0.01 |

| 25 | 6.0 - 9.9 | 0.015 | 0.005 | 0.01 |

| 40 | 10.0 - 17.9 | 0.02 | 0.005 | 0.01 |

| 50 | 18.0 - 26.9 | 0.02 | 0.005 | 0.01 |

| 60 | 27.0 - 34.0 | 0.02 | 0.005 | 0.01 |

- UP = Ultra Precision

- ER-UP collets must be used with HSP Claming Nut.

- The shank's concentricity must be less than h6.

| MODEL NO. | PCS / SET | COLLET KIT | WEIGHT (KGS) |

|---|---|---|---|

| SYIC - 04200 | ER8 x 9 | 5, 4.5, 4, 3.5, 3, 2.5, 2, 1.5, 1 | 0.15 |

| SYIC - 04201 | ER11 x 13 | 7, 6.5, 6, 5.5, 5, 4.5, 4, 3.5, 3, 2.5, 2, 1.5, 1 | 0.23 |

| SYIC - 04202 | ER16 x 10 | 10, 9, 8, 7, 6, 5, 4, 3, 2, 1 | 0.4 |

| SYIC - 04203 | ER20 x 12 | 13, 12, 11, 10, 9, 8, 7, 6, 5, 4, 3, 2 | 0.6 |

| SYIC - 04204 | ER25 x 15 | 16, 15, 14, 13, 12, 11, 10, 9, 8, 7, 6, 5, 4, 3, 2 | 1.7 |

| SYIC - 04205 | ER32 x 18 | 20, 19, 18, 17, 16, 15, 14, 13, 12, 11, 10, 9, 8, 7, 6, 5, 4, 3 | 2.6 |

| SYIC - 04206 | ER40 x 23 | 26, 25, 24, 23, 22, 21, 20, 19, 18, 17, 16, 15, 14, 13, 12, 11,10, 9, 8, 7, 6, 5, 4 | 6.6 |

| SYIC - 04207 | ER50 x 17 | 34, 32, 30, 28, 26, 24, 22, 20, 18, 16, 14, 12, 10, 9, 8, 7, 6 | 8.45 |

ER MIlling Chuck Set

- Whole set=(ER Collet x Q'yt)+spanner+body+plastic box.

- Please inform Draw Bar's thread when making an order.

| MODEL NO. | TYPE | COLLET SIZE | DRAW BAR | WEIGHT(KGS) |

|---|---|---|---|---|

| SYIC - 04902 | MTB3 x ER32 x 6PCS | 6, 8, 10, 12, 16, 20mm | M12 x 1.75P, 1/2" - 12 | 2.5 |

| SYIC - 04903 | MTB4 x ER32 x 6PCS | 6, 8, 10, 12, 16, 20mm | M16 x 2.0P, 5/8" - 11 | 2.7 |

| SYIC - 04904 | R8 x ER32 x 6PCS | 6, 8, 10, 12, 16, 20mm | 7/16" - 20 | 2.6 |

| SYIC - 04905 | NT30 x ER32 x 6PCS | 6, 8, 10, 12, 16, 20mm | M12 x 1.75P, 1/2" - 12 | 2.4 |

| SYIC - 04907 | MTB3 x ER40 x 7PCS | 6, 8, 10, 12, 16, 20, 25mm | M12 x 1.75P, 1/2" - 12 | 4.1 |

| SYIC - 04908 | MTB4 x ER40 x 7PCS | 6, 8, 10, 12, 16, 20, 25mm | M16 x 2.0P, 5/8" - 11 | 4 |

| SYIC - 04909 | R8 x ER40 x 7PCS | 6, 8, 10, 12, 16, 20, 25mm | 7/16" - 20 | 3.9 |

| SYIC - 04910 | NT30 x ER40 x 7PCS | 6, 8, 10, 12, 16, 20, 25mm | M12 x 1.75P, 1/2" - 12 | 3.8 |

| SYIC - 04911 | NT40 x ER40 x 7PCS | 6, 8, 10, 12, 16, 20, 25mm | M16 x 2.0P, 5/8" - 11 | 3.9 |

| SYIC - 04913 | MTB3 x ER32 x 18PCS | 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13,14, 15, 16, 17, 18, 19, 20mm |

M12 x 1.75P, 1/2" - 12 | 4 |

| SYIC - 04914 | MTB4 x ER32 x 18PCS | 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13,14, 15, 16, 17, 18, 19, 20mm |

M16 x 2.0P, 5/8" - 11 | 4.15 |

| SYIC - 04915 | R8 x ER32 x 18PCS | 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13,14, 15, 16, 17, 18, 19, 20mm |

7/16" - 20 | 4 |

| SYIC - 04916 | NT30 x ER32 x 18PCS | 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13,14, 15, 16, 17, 18, 19, 20mm |

M12 x 1.75P, 1/2" - 12 | 4 |

| SYIC - 04917 | NT40 x ER32 x 18PCS | 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13,14, 15, 16, 17, 18, 19, 20mm |

M16 x 2.0P, 5/8" - 11 | 4.3 |

| SYIC - 04919 | MTB4 x ER40 x 23PCS | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,15, 16, 17, 18, 19, 20, 21, 22,23, 24, 25, 26mm |

M16 x 2.0P, 5/8" - 11 | 8.45 |

| SYIC - 04920 | R8 x ER40 x 23PCS | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,15, 16, 17, 18, 19, 20, 21, 22,23, 24, 25, 26mm |

7/16" - 20 | 8.3 |

| SYIC - 04921 | NT30 x ER40 x 23PCS | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,15, 16, 17, 18, 19, 20, 21, 22,23, 24, 25, 26mm |

M12 x 1.75P, 1/2" - 12 | 8 |

| SYIC - 04922 | NT40 x ER40 x 23PCS | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,15, 16, 17, 18, 19, 20, 21, 22,23, 24, 25, 26mm |

M16 x 2.0P, 5/8" - 11 | 8.45 |

| SYIC - 04923 | NT50 x ER40 x 23PCS | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,15, 16, 17, 18, 19, 20, 21, 22,23, 24, 25, 26mm |

M24 x 3.0P, 1" - 8 | 11.25 |

| SYIC - 04925 | NT40 x ER50 x 17PCS | 6, 7, 8, 9, 10, 12, 14, 16, 18,20 , 22, 24, 26, 28, 30, 32, 34mm |

M16 x 2.0P, 5/8" - 11 | 9.15 |

| SYIC - 04926 | NT50 x ER50 x 17PCS | 6, 7, 8, 9, 10, 12, 14, 16, 18,20, 22, 24, 26, 28, 30, 32, 34mm |

M24 x 3.0P, 1" - 8 | 11.95 |

| SYIC - 04930 | MTB3 x ER40 x 15PCS | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18, 20, 21, 23, 25, 26mm |

M12 x 1.75P, 1/2" - 12 | 6.45 |

| SYIC - 04931 | MTB4 x ER40 x 15PCS | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18,20, 21, 23, 25, 26mm |

M16 x 2.0P, 5/8" - 11 | 6.45 |

| SYIC - 04932 | R8 x ER40 x 15PCS | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18,20, 21, 23, 25, 26mm |

7/16" - 20 | 6.3 |

| SYIC - 04933 | NT30 x ER40 x 15PCS | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18,20, 21, 23, 25, 26mm |

M12 x 1.75P, 1/2" - 12 | 6 |

| SYIC - 04934 | NT40 x ER40 x 15PCS | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18,20, 21, 23, 25, 26mm |

M16 x 2.0P, 5/8" - 11 | 6.45 |

| SYIC - 04935 | NT50 x ER40 x 15PCS | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18,20, 21, 23, 25, 26mm |

M24 x 3.0P, 1" - 8 | 9.25 |

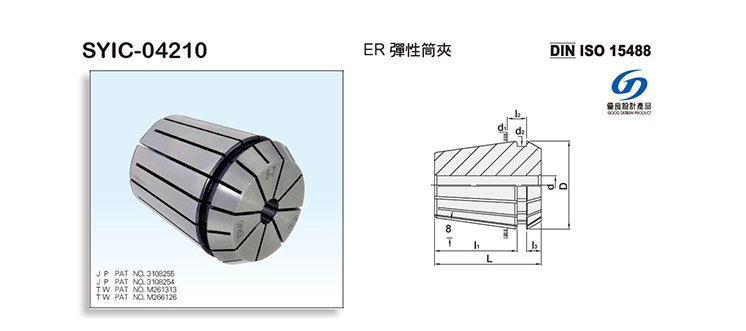

ER Collet

- Design: 8 slots in front and back, with good flexibility and convenient for clamping tools.

- Steel: SUJ2 (High-carbon bearing steel: After heat treatment, it has high hardness and toughness, better grinding quality, good flexibility and longer use life.)

- HRC: 46°

- Surface roughness: within Rz2.5

- Chucking range: ER8 = 0.5mm

- ER11, 16, 20, 25, 32, 40 = 1mm. But if the internal hole is less than 2.5mm, the chucking range will be 0.5mm.

- The internal hole is manufactured by precise honing.

- The concentricity is inspected according to DIN-standard. There are three classes of precision: general class 0.02mm, A class 0.01mm.

- UP class is recommended to be used with HSP clamping nut. It will have better processing stability.

- It is used for drills, taps, mills, and reamers, etc.

- It has flexibility and can be applied widely and variably.

- Please inform the required precision when ordering.

- Yearly sales quantity about 1,000,000 piece

| MODEL NO. | TYPE | E - NO. | SIZE RANGE | D | d1 | L | l1 | l2 | l3 | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|

| SYIC - 04208 | ER8 | 4260E | 1.0 ~ 5.0 | 8.5 | 8 | 13.5 | 10.8 | 2.98 | 1.5 | 0.005 |

| SYIC - 04211 | ER11 | 4009E | 1.0 ~ 7.0 | 11.5 | 11 | 18 | 13.5 | 3.8 | 2.5 | 0.01 |

| SYIC - 04216 | ER16 | 426E | 1.0 ~ 10 | 17 | 16 | 27.5 | 20.8 | 6.26 | 4 | 0.03 |

| SYIC - 04220 | ER20 | 428E | 2.0 ~ 13 | 21 | 20 | 31.5 | 23.9 | 6.36 | 4.8 | 0.04 |

| SYIC - 04225 | ER25 | 430E | 2.0 ~ 16 | 26 | 25 | 34 | 25.9 | 6.66 | 5 | 0.06 |

| SYIC - 04232 | ER32 | 470E | 3.0 ~ 20 | 33 | 32 | 40 | 30.9 | 7.16 | 5.5 | 0.1 |

| SYIC - 04240 | ER40 | 472E | 3.0 ~ 26 | 41 | 40 | 46 | 34.9 | 7.66 | 7 | 0.25 |

| SYIC - 04250 | ER50 | 477E | 6.0 ~ 34 | 52 | 50 | 60 | 46 | 13.4 | 8.5 | 0.45 |

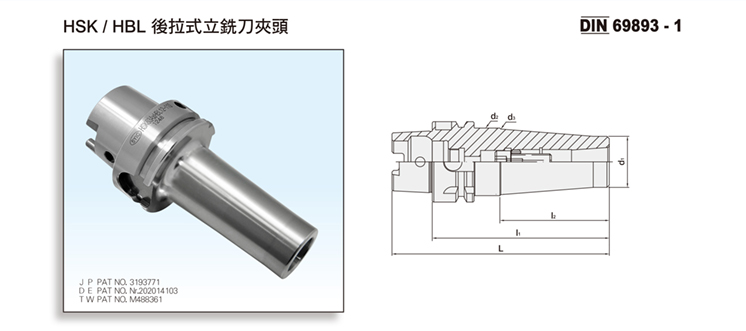

HSK/HBL SLIM-FIT COLLET CHUCK FOR TYPE A

- Every tool holder reaches the revolution of G2.5 25,000 rpm, with an inspection report.

- The balancing grade and revolution can be done according to customer request but the additional charge is needed.

| MODEL NO. | TYPE - l1 | L | l2 | d1 | d2 | d3 | T |

|---|---|---|---|---|---|---|---|

| 35456H | HSK50A x HBL12 - 110 | 135 | 68 | 31.75 | 42 | 40.79 | M10 x 1.5P |

| 35458H | HSK50A x HBL12 - 130 | 155 | 75.12 | 31.75 | 42 | - | M10 x 1.5P |

| 35460H | HSK50A x HBL20 - 120 | 145 | 54.66 | 38.1 | 42 | - | M12 x 1.75P |

| 35462H | HSK50A x HBL20 - 150 | 175 | 54.45 | 38.1 | 42 | - | M12 x 1.75P |

| 35476H | HSK63A x HBL12 - 110 | 142 | 79.22 | 31.75 | 37.79 | - | M10 x 1.5P |

| 35478H | HSK63A x HBL12 - 150 | 182 | 119.22 | 31.75 | 41.29 | - | M10 x 1.5P |

| 35480H | HSK63A x HBL20 - 120 | 152 | 89.22 | 38.1 | 45.02 | - | M12 x 1.75P |

| 35482H | HSK63A x HBL20 - 140 | 172 | 111.13 | 38.1 | 45 | - | M12 x 1.75P |

| 35494H | HSK100A x HBL12 - 120 | 170 | 79.05 | 31.75 | 37.78 | - | M10 x 1.5P |

| 35496H | HSK100A x HBL20 - 135 | 185 | 89.02 | 38.1 | 45 | - | M12 x 1.75P |

| 35498H | HSK100A x HBL25 - 150 | 200 | 118.13 | 44.45 | 53.89 | - | M24 x 1.5P |

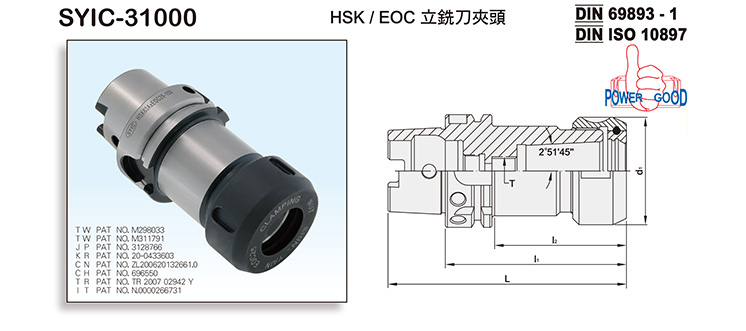

HSK /EOC COLLET CHUCK FOR TYPE A

- Each collet chuck is supplied with a nut but not including spanner and collet.

- Every tool holder reaches the standard of G2.5 25,000 rpm, with an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is nee

| MODEL NO. | TYPE l1 | L | l2 | d1 | T | SIZE RANGE | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|

| SYIC - 31002 | HSK50A x EOC16 - 100 | 125 | 74 | 43 | M12 x 1.75P | 2.0 ~ 16 | 0.7 |

| SYIC - 31004 | HSK50A x EOC16 - 120 | 145 | 94 | 43 | M12 x 1.75P | 2.0 ~ 16 | 0.9 |

| SYIC - 31006 | HSK50A x EOC25 - 100 | 125 | 58 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.1 |

| SYIC - 31008 | HSK50A x EOC25 - 120 | 145 | 78 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.3 |

| SYIC - 31010 | HSK50A x EOC25 - 150 | 175 | 108 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.5 |

| SYIC - 31012 | HSK50A x EOC32 - 120 | 145 | 78 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2.1 |

| SYIC - 31014 | HSK50A x EOC32 - 150 | 175 | 108 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2.3 |

| SYIC - 31022 | HSK63A x EOC16 - 100 | 132 | 69 | 43 | M12 x 1.75P | 2.0 ~ 16 | 1.1 |

| SYIC - 31024 | HSK63A x EOC16 - 120 | 152 | 89 | 43 | M12 x 1.75P | 2.0 ~ 16 | 1.2 |

| SYIC - 31026 | HSK63A x EOC25 - 100 | 132 | 72 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.3 |

| SYIC - 31028 | HSK63A x EOC25 - 120 | 152 | 92 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.5 |

| SYIC - 31030 | HSK63A x EOC25 - 150 | 182 | 122 | 60 | M16 x 2.0P | 3.0 ~ 25 | 1.7 |

| SYIC - 31032 | HSK63A x EOC32 - 120 | 152 | 78 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2.3 |

| SYIC - 31034 | HSK63A x EOC32 - 150 | 182 | 108 | 72 | M20 x 2.0P | 4.0 ~ 32 | 2.5 |

| SYIC - 31042 | HSK100A x EOC16 - 100 | 150 | 61 | 43 | M12 x 1.75P | 2.0 ~ 16 | 3.4 |

| SYIC - 31044 | HSK100A x EOC16 - 120 | 170 | 81 | 43 | M12 x 1.75P | 2.0 ~ 16 | 3.6 |

| SYIC - 31046 | HSK100A x EOC25 - 100 | 150 | 61 | 60 | - | 3.0 ~ 25 | 3.5 |

| SYIC - 31048 | HSK100A x EOC25 - 120 | 170 | 81 | 60 | M16 x 2.0P | 3.0 ~ 25 | 3.7 |

| SYIC - 31050 | HSK100A x EOC25 - 150 | 200 | 111 | 60 | M16 x 2.0P | 3.0 ~ 25 | 4.1 |

| SYIC - 31052 | HSK100A x EOC32 - 130 | 180 | 91 | 72 | M20 x 2.0P | 4.0 ~ 32 | 4.5 |

| SYIC - 31054 | HSK100A x EOC32 - 150 | 200 | 111 | 72 | M20 x 2.0P | 4.0 ~ 32 | 4.7 |

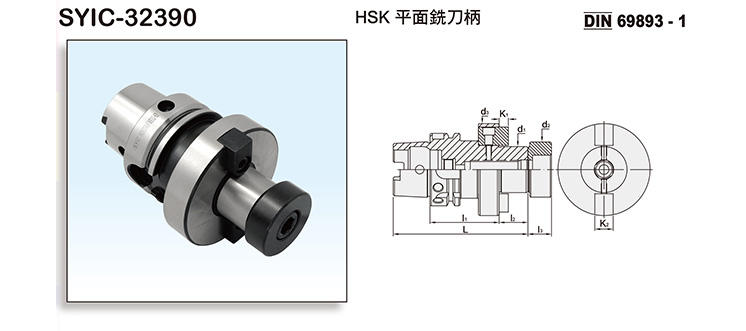

HSK FACE MILL ARBOR FOR TYPE A

- d1 tolerance: h6.

- The pre-balance can reach G6.3 3,000 rpm, without an inspection report.

- The balancing grade and revolution can be done according to customer's request but the additional charge is needed.

| MODEL NO. | TYPE d1 - l1 | L | l2 | l3 | d2 | d3 | K1 | K2 | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|

| SYIC - 32392 | HSK40A x FMB16 - 50 | 87 | 17 | - | - | 40 | 3.8 | 8 | 0.7 |

| SYIC - 32394 | HSK40A x FMB22 - 60 | 99 | 19 | 14 | 26 | 52 | 4.8 | 10 | 0.8 |

| SYIC - 32396 | HSK40A x FMB27 - 60 | 101 | 21 | 16 | 31.5 | 60 | 5.8 | 12 | 1 |

| SYIC - 32398 | HSK40A x FMB32 - 60 | 104 | 24 | 16 | 41 | 78 | 6.8 | 14 | 1.1 |

| SYIC - 32402 | HSK50A x FMB16 - 50 | 92 | 17 | - | - | 40 | 3.8 | 8 | 1.1 |

| SYIC - 32404 | HSK50A x FMB22 - 60 | 104 | 19 | 14 | 26 | 48 | 4.8 | 10 | 1 |

| SYIC - 32406 | HSK50A x FMB27 - 60 | 106 | 21 | 16 | 31.5 | 60 | 5.8 | 12 | 1.3 |

| SYIC - 32408 | HSK50A x FMB32 - 60 | 109 | 24 | 16 | 41 | 78 | 6.8 | 14 | 1.5 |

| SYIC - 32412 | HSK63A x FMB16 - 50 | 99 | 17 | - | - | 40 | 3.8 | 8 | 1.2 |

| SYIC - 32414 | HSK63A x FMB22 - 50 | 101 | 19 | 14 | 26 | 50 | 4.8 | 10 | 1.3 |

| SYIC - 32416 | HSK63A x FMB27 - 60 | 113 | 21 | 16 | 31.5 | 53 | 5.8 | 12 | 1.5 |

| SYIC - 32418 | HSK63A x FMB32 - 60 | 116 | 24 | 16 | 41 | 78 | 6.8 | 14 | 1.6 |

| SYIC - 32420 | HSK63A x FMB40 - 60 | 117 | 25 | 20.5 | 48 | 80 | 8.3 | 16 | 2.1 |

| SYIC - 32442 | HSK100A x FMB22 - 50 | 119 | 19 | 14 | 26 | 48 | 4.8 | 10 | 2.7 |

| SYIC - 32444 | HSK100A x FMB27 - 50 | 121 | 21 | 16 | 31.5 | 60 | 5.8 | 12 | 2.9 |

| SYIC - 32446 | HSK100A x FMB32 - 50 | 124 | 24 | 16 | 41 | 78 | 6.8 | 14 | 3 |

| SYIC - 32448 | HSK100A x FMB40 - 60 | 135 | 25 | 20.5 | 48 | 80 | 8.3 | 16 | 4 |

| SYIC - 32450 | HSK100A x FMB50 - 70 | 150 | 30 | 25 | 68 | 120 | 9.7 | 19 | 5.1 |

| SYIC - 32452 | HSK100A x FMB60 - 70 | 160 | 40 | - | - | 129 | 12.5 | 25.4 | 5.5 |

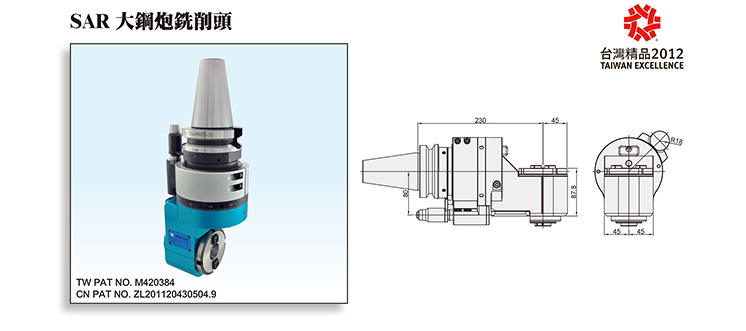

BT/SAR Angle Head Holder

| EL NO. | TYPE | TORQUE | WEIGHT (KGS) |

|---|---|---|---|

| SYIC - 12.643 | BT50 x SAR50 / BT30 - 230 | 50 N-m | 16.1 |

| SYIC - 27.643 | SBT50 x SAR50 / BT30 - 230 | 50 N-m | 16.1 |

- The spindle chuck is designed to be #30 taper type, which can be used to match multiple and suitable adapters according to different processing requirements.

- Gear ratio 1:1, the spindle doesn’t need to turn counterclockwise.

- The fixed block is available for coolant system.

- The design of angle scale enables users to easily adjust to the processing angles they need.

- Max. revolution: 3000 rpm.

- Standard taper for the spindle chuck is #30(BT30). Other types of taper can be custom-made.

- Water pressure: 7kgf/cm².

Matched Adapters:

| MODEL NO. | TYPE | d1 | SIZE RANGE |

|---|---|---|---|

| 25.122.16.050 | SBT30 x ER16A - 50 | 28 | Ø1.0 ~Ø10 |

| 25.122.16.070 | SBT30 x ER16A - 70 | 28 | Ø1.0 ~Ø10 |

| 25.122.20.050 | SBT30 x ER20A - 50 | 34 | Ø1.0 ~Ø13 |

| 25.122.20.070 | SBT30 x ER20A - 70 | 34 | Ø1.0 ~Ø13 |

| 25.122.25.070 | SBT30 x ER25 - 70 | 42 | Ø1.0 ~Ø16 |

| 25.122.32.070 | SBT30 x ER32 - 70 | 50 | Ø2.0 ~Ø20 |

| MODEL NO. | TYPE | d1 | l2 |

|---|---|---|---|

| 25.151.68.045 | SBT30 x FMA25.4 - 45 | 25.4 | 20 |

| 25.153.22.045 | SBT30 x FMB22 - 45 | 22 | 19 |

| 25.153.27.045 | SBT30 x FMB27 - 45 | 27 | 20 |

| MODEL NO. | TYPE | d1 | SIZE RANGE |

|---|---|---|---|

| 25.658.06.045 | SBT30 x SKS6 - 45 | 18 | Ø1.0 ~Ø6 |

| 25.658.06.060 | SBT30 x SKS6 - 60 | 18 | Ø1.0 ~Ø6 |

| 25.658.10.045 | SBT30 x SKS10 - 45 | 30 | Ø2.0 ~Ø10 |

| 25.658.10.060 | SBT30 x SKS10 - 60 | 30 | Ø2.0 ~Ø10 |

| 25.658.13.060 | SBT30 x SKS13 - 60 | 35 | Ø3.0 ~Ø13 |

| 25.658.16.060 | SBT30 x SKS16 - 60 | 40 | Ø3.0 ~Ø16 |

| 25.658.20.060 | SBT30 x SKS20 - 60 | 48.5 | Ø3.0 ~Ø20 |

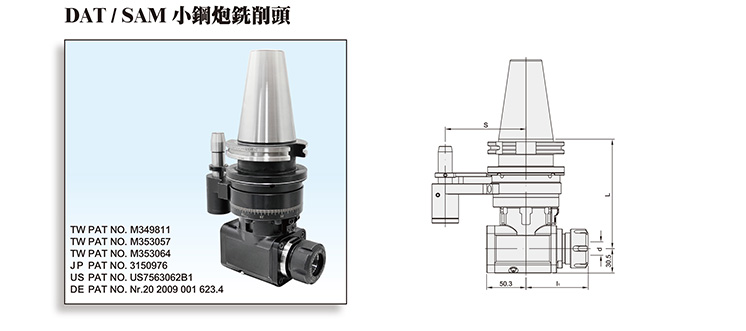

SAM Angle Head Holder

WITH COOLANT SYSTEM

| MODEL NO. | TYPE | L | l1 | SIZE RANGE | S | TORQUE | COLLET | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|

| 51.635.10.136 | DAT40 x SAM10S - 136.45 | 136.45 | 87 | Ø 2.0 ~ Ø 10 | 65 | 20 N-m | SKS10 | 5.2 |

| 51.635.13.136 | DAT40 x SAM13S - 136.45 | 136.45 | 87 | Ø 3.0 ~ Ø 13 | 65 | 20 N-m | SKS13 | 5.2 |

| 51.635.16.136 | DAT40 x SAM16S - 136.45 | 136.45 | 89.5 | Ø 3.0 ~ Ø 16 | 65 | 20 N-m | SKS16 | 5.2 |

| 51.635.20.136 | DAT40 x SAM20S - 136.45 | 136.45 | 90 | Ø 3.0 ~ Ø 20 | 65 | 20 N-m | SKS20 | 5.2 |

| 51.636.16.136 | DAT40 x SAM16E - 136.45 | 136.45 | 87 | Ø 1.0 ~ Ø 10 | 65 | 20 N-m | ER16 | 5.2 |

| 51.636.20.136 | DAT40 x SAM20E - 136.45 | 136.45 | 87 | Ø 1.0 ~ Ø 13 | 65 | 20 N-m | ER20 | 5.2 |

| 51.636.25.136 | DAT40 x SAM25E - 136.45 | 136.45 | 87 | Ø 1.0 ~ Ø 16 | 65 | 20 N-m | ER25 | 5.2 |

| 51.636.32.136 | DAT40 x SAM32E - 136.45 | 136.45 | 82 | Ø 2.0 ~ Ø 20 | 65 | 20 N-m | ER32 | 5.2 |

| 52.635.10.139 | DAT50 x SAM10S - 139.7 | 139.7 | 87 | Ø 2.0 ~ Ø 10 | 80 | 20 N-m | SKS10 | 6.3 |

| 52.635.13.139 | DAT50 x SAM13S - 139.7 | 139.7 | 87 | Ø 3.0 ~ Ø 13 | 80 | 20 N-m | SKS13 | 6.3 |

| 52.635.16.139 | DAT50 x SAM16S - 139.7 | 139.7 | 89.5 | Ø 3.0 ~ Ø 16 | 80 | 20 N-m | SKS16 | 6.3 |

| 52.635.20.139 | DAT50 x SAM20S - 139.7 | 139.7 | 90 | Ø 3.0 ~ Ø 20 | 80 | 20 N-m | SKS20 | 6.3 |

| 52.636.16.139 | DAT50 x SAM16E - 139.7 | 139.7 | 87 | Ø 1.0 ~ Ø 10 | 80 | 20 N-m | ER16 | 6.3 |

| 52.636.20.139 | DAT50 x SAM20E - 139.7 | 139.7 | 87 | Ø 1.0 ~ Ø 13 | 80 | 20 N-m | ER20 | 6.3 |

| 52.636.25.139 | DAT50 x SAM25E - 139.7 | 139.7 | 87 | Ø 1.0 ~ Ø 16 | 80 | 20 N-m | ER25 | 6.3 |

| 52.636.32.139 | DAT50 x SAM32E - 139.7 | 139.7 | 82 | Ø 2.0 ~ Ø 20 | 80 | 20 N-m | ER32 | 8.86 |

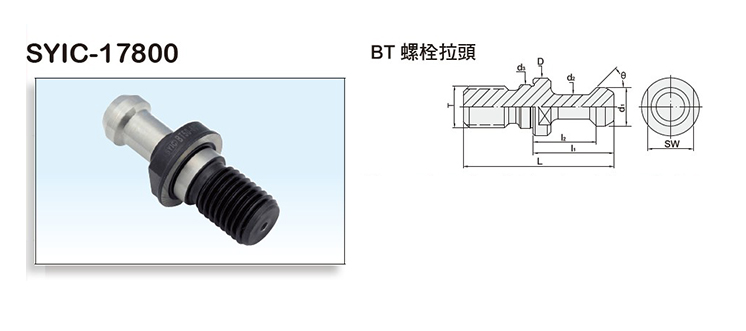

BT Pull Studs

- Please make sure the pull stud conforms to the machine type.

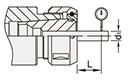

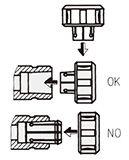

- The lnstallation and Disassembly Way for PullStud:

| MODEL NO. | TYPEθ | D | d1 | d2 | d3 | L | l1 | l2 | T | SW | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SYIC - 17801 | BT30 - 45° | 16.5 | 11 | 7 | 12.5 | 43 | 23 | 18 | M12 | 13 | 0.04 |

| SYIC - 17803 | BT40 - 45° | 23 | 15 | 10 | 17 | 60 | 35 | 28 | M16 | 19 | 0.1 |

| SYIC - 17805 | BT50 - 45° | 38 | 23 | 17 | 25 | 85 | 45 | 35 | M24 | 30 | 0.3 |

| SYIC - 17806 | BT30 - 60° | 16.5 | 11 | 7 | 12.5 | 43 | 23 | 18 | M12 | 13 | 0.04 |

| SYIC - 17808 | BT40 - 60° | 23 | 15 | 10 | 17 | 60 | 35 | 28 | M16 | 19 | 0.1 |

| SYIC - 17810 | BT50 - 60° | 38 | 23 | 17 | 25 | 85 | 45 | 35 | M24 | 30 | 0.3 |

| SYIC - 17812 | BT30 - 90° | 16.5 | 11 | 7 | 12.5 | 43 | 23 | 18 | M12 | 13 | 0.04 |

| SYIC - 17814 | BT40 - 90° | 23 | 15 | 10 | 17 | 60 | 35 | 28 | M16 | 19 | 0.1 |

| SYIC - 17816 | BT50 - 90° | 38 | 23 | 17 | 25 | 85 | 45 | 35 | M24 | 30 | 0.3 |

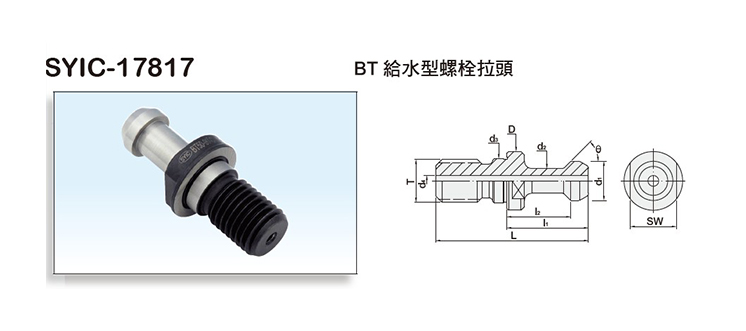

BT Pull Studs Coolant Type

- Please make sure the pull stud conforms to the machine type.

| MODEL NO. | TYPEθ | D | d1 | d2 | d3 | d4 | L | l1 | l2 | T | SW | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SYIC - 17817 | BT30 - 45° | 16.5 | 11 | 7 | 12.5 | 3 | 43 | 23 | 18 | M12 | 13 | 0.1 |

| SYIC - 17818 | BT40 - 45° | 23 | 15 | 10 | 17 | 4 | 60 | 35 | 28 | M16 | 19 | 0.1 |

| SYIC- 17818 - MAZAK | BT40 - 45° | 22 | 18.79 | 12.44 | 17 | 7 | 44.1 | 19.1 | 14.02 | M16 | 19 | 0.1 |

| SYIC - 17820 | BT40 - 60° | 23 | 15 | 10 | 17 | 4 | 60 | 35 | 28 | M16 | 19 | 0.1 |

| SYIC - 17822 | BT40 - 90° | 23 | 15 | 10 | 17 | 4 | 60 | 35 | 28 | M16 | 19 | 0.1 |

| SYIC - 17824 | BT50 - 45° | 38 | 23 | 17 | 25 | 5 | 85 | 45 | 35 | M24 | 30 | 0.3 |

| SYIC- 17824 - MAZAK | BT50 - 45° | 35.5 | 28.95 | 20.8 | 25 | 10 | 65.4 | 25.4 | 17.78 | M24 | 30 | 0.3 |

| SYIC - 17826 | BT50 - 60° | 38 | 23 | 17 | 25 | 5 | 85 | 45 | 35 | M24 | 30 | 0.3 |

| SYIC - 17828 | BT50 - 90° | 38 | 23 | 17 | 25 | 5 | 85 | 45 | 35 | M24 | 30 | 0.3 |