HEULE Customized Tools

One Operation. Tools tailored to your specific application needs continue several operations in one single pass.

Economic front and back chamfering in One Operation, with very easy blade changes

| TECHNICAL | PROGRAMMING | ||||

| APPLICATIONS | APPLICATION DATA SHEET | TESTIMONIAL | |||

|

|||||

|

The SNAP chamfering tool is the answer for today's manufacturing requiring simpler and more flexible solutions without sacrificing quality or tool life. SNAP is a very simple tool for deburring and/or chamfering through holes on the top and bottom without reversing the spindle, dwelling, or indexing the part. The SNAP tool offers a simple to use high quality chamfering tool with Carbide inserts coated with TiN, TiCN, or TiAIN to meet today's manufacturing needs.

SNAP is a single bladed tool for deburring and chamfering the front and back of a through hole in one operation. SIMPLE - the easy to use tool requires no tools and no adjustments. Changing the blade is as easy as pushing out the old and putting in a new blade.

|

|||||

| Application Examples | |||||

|

|

|||||

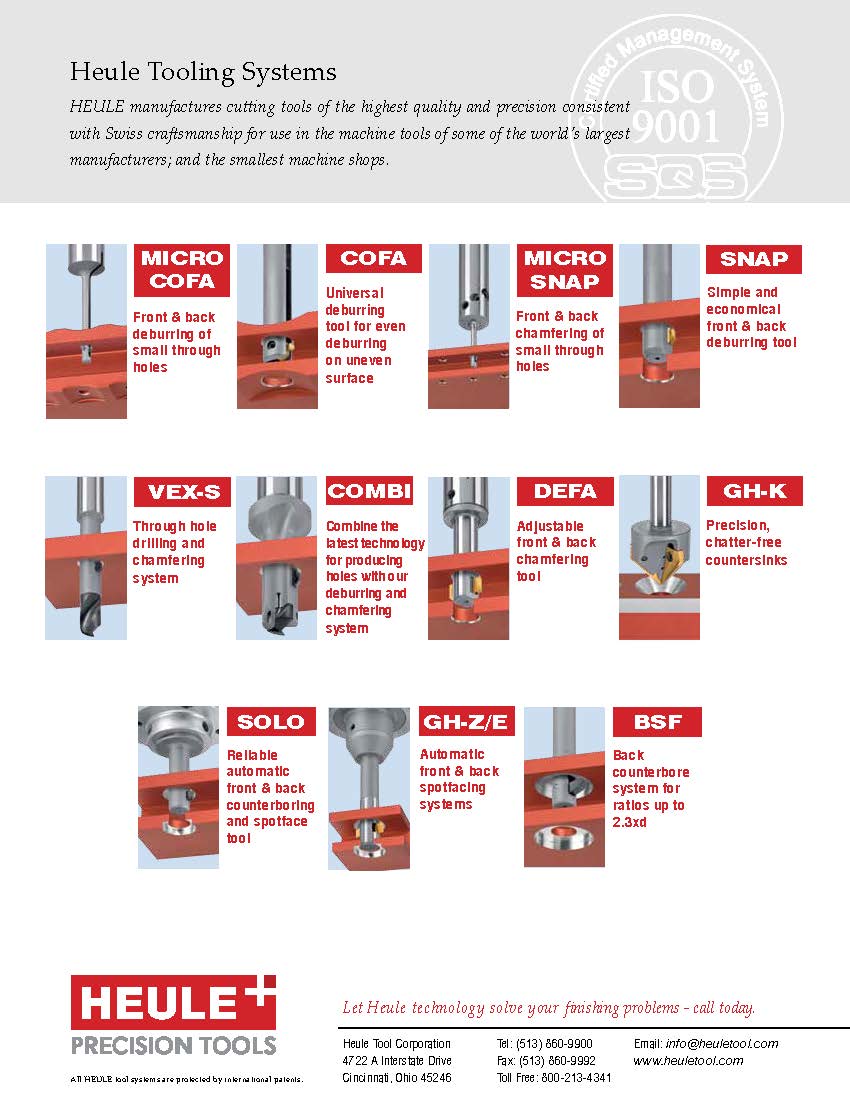

Economic front and back chamfering in One Operation, with very easy blade changes.

The double bladed DEFA chamfering tool creates predefined front and back chamfers in a single operation without stopping or reversing the spindle.

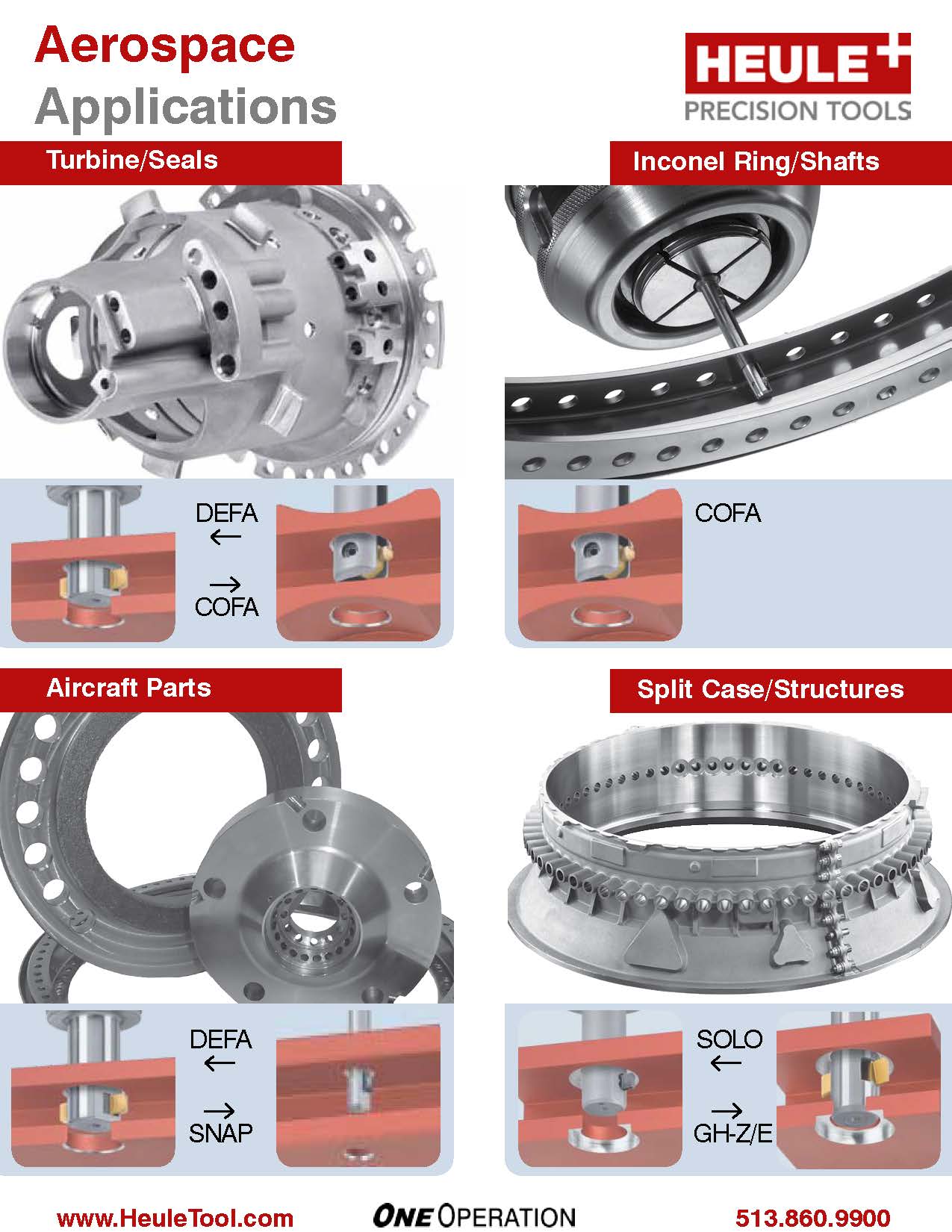

Adjustable chamfering of interrupted bore edges, front and back in One Operation.

Consistent deburring of even and uneven bore edges, front and back in One Operation.

Economic front and back chamfering in One Operation, with very easy blade changes.

The surprisingly simple BSF tool concept allows back spotfacing or back counterboring in one operation without turning the workpiece.

The SOLO tool allows for production of front and back countersinks and back spotfacing of through-holes with positive control in One Operation without requiring the work piece to be turned.

The GH-Z/E tool is a twin bladed front and back counterboring tool that produces accurate back spotfaces, large countersinks and precision forms.

Chatter-free front countersinking of a big countersink range with one single tool.

Efficient combination of drilling, front and back chamfering in One Operation in the range of Ø5.0 until 11.5 mm.

Efficient combination of drilling, front and back chamfering in One Operation in the range of Ø11.0 - 17.0 mm.

One Operation. Tools tailored to your specific application needs continue several operations in one single pass.

Work piece geometry, material, fixturing, machining process and the requirements that cutting tools are expected to fulfill vary from industry to industry. Since no application is like any other, HEULE's unique cutting tool line offers standard and specialty tools for all your technical needs.

As solution finders, we take up this challenge. We offer you specific tools that are tailored to your individual application and will therefore offer you the best possible performance. On the basis of our standard technologies, we combine multiple operations in a single tool or adapt tool dimensions and blades to suit your machining concept. Thanks to our in-house development and manufacture of all components, we are flexible, dependable, and fast.

HEULE Cassette tool with Special tool holder for the deburring of large bore diameters.

Back Spot Facing tool with adapted working length for simple and cost-effective backward machining

The process capable deburring of Common Rail applications has been assured by HEULE for years now.

Deburring of Cross Bores.

With X-BORES HEULE takes up the challenge to provide solutions for the automated deburring of cross bores. Existing technologies soon run into their limits. The deburring by means of a defined cutting edge in a chip making process brings up major advantages.

Modern components increasingly have more complex geometries and are made of new materials or material combinations. Furthermore, the demans on the deburring quality, the process capability and the efficiency that have to be met are rising continuously.

HEULE as an experience problem solver offers customer-optimized solutions based on four different tool systems:

Economic front and back chamfering in One Operation, with very easy blade changes.

The SNAP tool is an efficient front and back chamfering tool that is easy to use and which allows quick blade changes, making it a convenient solution for any manufacturing environment. Without any need to turn the work piece or to stop the spindle, it removes the burrs and chamfers the edges. The SNAP tool has been designed for automatic operation involving large production lots.

The SNAP chamfering blade is held by a spring-loaded control bolt inside the tool body so that it can move. The specially ground SNAP blade for front and back or only back cutting generates the desired chamfer by forward feed. As soon as the defined chamfer thickness has been achieved, the SNAP blade radially enters the tool body. The chamfer thickness and angle are geometrically defined on the SNAP blade and can only be modified by inserting a SNAP blade with different specifications. When it exits the bore, the SNAP blade returns to its home position via the spring-loaded control bolt. A specially designed sliding section prevents the bore from being injured. It is also possible to penetrate reamed bores without risk of damage. The result is exceptional front and back chamfering in One Operation.

The operation is very simple. The tool blade is moved by rapid motion to a point ahead of the top bore edge. The top bore edge is machined by forward feed and with the working RPM. When the chamfer thickness has been achieved, the SNAP blade automatically enters the tool body. Now the tool moves by rapid motion and without stopping the spindle through the bore until the SNAP blade has again been extended at the back of the work piece. Now the back bore edge is chamfered by backward feed. When the chamfer has been produced, the tool moves out of the bore again by rapid motion.

The tool assortment is comprised of tools for bore diameters of 2 mm to 35 mm. Cassettes allow bore diameters of any size to be processed. The chamfer thickness is 0.1 mm to 1.5 mm, depending on the blade selected. Within the tool series, diameter versions are available which cover a minimum bore diameter. For details, please see the technical documentation.

| Tool series | Bore | Max. chamfer size |

|---|---|---|

| SNAP2 | Ø2.0 – Ø2.9 mm | 0.2 - 0.3 |

| SNAP3 | Ø3.0 – Ø3.9 mm | 0.3 - 0.5 |

| SNAP4 | Ø4.0 – Ø5.0 mm | 0.6 - 0.75 |

| SNAP5 | Ø5.0 – Ø8.0 mm | 1.0 |

| SNAP8 | Ø8.0 – Ø12.0 mm | 0.75 |

| SNAP12 | Ø12.0 – Ø20.0 mm | 1.0 |

| SNAP20 | Ø20.0 – Ø35.0 mm | 1.5 |

| SNAP5 Cassette | from Ø12.6 mm | 1.5 |

| SNAP20 Cassette | from Ø25.0 mm | 1.5 |

| SNAP20 Cassette | from Ø35.0 mm | 1.5 |

| SNAP2/M2.5 | Thread M2.5 Ø2.05 mm | 0.35 |

| SNAP2/M3 | Thread M3 Ø2.5 mm | 0.45 |

| SNAP3/M4 | Thread M4 Ø3.3 mm | 0.6 |

| SNAP4/M5 | Thread M5 Ø4.2 mm | 0.7 |

| SNAP5/M6 | Thread M6 Ø5.0 mm | 0.75 |

| SNAP5/M8 | Thread M8 Ø6.8 mm | 0.85 |

| SNAP5/M10 | Thread M10 Ø8.5 mm | 1.0 |

| SNAP5/M12 | Thread M12 Ø10.2 mm | 1.15 |

| SNAP5/M14 | Thread M14 Ø12.0 mm | 1.25 |

Automotive Industry / Connecting Rod

HEULE has been reducing cycle times in the automotive industry successfully for over 30 years now. Today, car manufacturers ask for simple and process capable tool system. Terms like "time saving activities", "labor costs saving“ and "CIP continuous improvement process“ are common practice in the automotive industry

Our customer has been machining the connecting rods manually for years.

| Bore | Ø62.5 mm |

| Deburring size | Ø63.5 mm |

| Unevenness | 20° |

| Material | Forged steel |

The HEULE proposal stipulates a cassette solution with the COFA tool. The standard COFA cassette can be adapted easily to large bore diameters by using a customized tool holder. This method gives the freedom to use the standard cassette also for other deburring applications.

The burrs will be removed at the front and at the back without any problems. Due to the unevenness of the bore edge, the radial deburring will be slightly irregular.

The connecting rod is clamped on a undefined surface. As a result, the deburring surface is also undefined which is asking necessarily for a spring-guided deburring system that compensates for the variance.

The COFA blade does not hurt the already finished bore surface when traversing the hole. It is recommendable to apply low cutting values in order to allow the COFA blade to adapt to the contour.

Connecting rod / Main bore

| Working speed |

300 rpm |

| Working feed |

0.15 mm/rev. |

| Coolant |

External cooling |

| TECHNICAL | PROGRAMMING | ||||

| APPLICATIONS | APPLICATION DATA SHEET | TESTIMONIAL | |||

|

|||||

|

The SNAP chamfering tool is the answer for today's manufacturing requiring simpler and more flexible solutions without sacrificing quality or tool life. SNAP is a very simple tool for deburring and/or chamfering through holes on the top and bottom without reversing the spindle, dwelling, or indexing the part. The SNAP tool offers a simple to use high quality chamfering tool with Carbide inserts coated with TiN, TiCN, or TiAIN to meet today's manufacturing needs.

SNAP is a single bladed tool for deburring and chamfering the front and back of a through hole in one operation. SIMPLE - the easy to use tool requires no tools and no adjustments. Changing the blade is as easy as pushing out the old and putting in a new blade.

|

|||||

| Application Examples | |||||

|

Click here for case study. |

|||||

This automotive component manufacturer uses SNAP tools on a rotary transfer machine to ensure quality and extended tool life when chamfering the through holes in this reactionary gear carrier for an automatic transmission.

The SNAP tool runs at 450SFM and 28ipm which significantly reduced their previous cycle time. In addition, the tool life is in excess of 20,000 holes which is more than four times the previous chamfer tool.

This automotive component manufacturer uses SNAP tools on a rotary transfer machine to chamfer the bolt holes in this differential housing.

The SNAP tool runs at 200SFM and 12ipm and the tool life is in excess of 24,000 holes.

Automotive Industry / Common Rail

The process capable deburring of Common Rail applications has been assured by HEULE for years now. Various manufacturers appreciate the reliability of the tools as well as the support and the experience of the HEULE team.

By the increasing demands just as well as the strategic targets related to cost optimization hte subcontracting industry is facing new challenges almost on a daily basis. The edges of the back bores have to be processed very carefully: no grooves, no irregularities or any traces are permitted. The back edges of the bores undergo a 100 % quality check.

HEULE was confronted with the following application parameters:

|

Bore |

Ø2.4 ±0.05 mm |

|

Main bore |

Ø9.0 mm |

|

Unevenness |

0.22 mm |

|

Deburring backward only |

approx. Ø2.8 mm |

|

Material |

20MnCr5, forged part |

|

Machine |

2 Axis-horizontal machining centres |

This application represented a challenge to HEULE Werkzeug AG because of the relatively small bore as well as the height of the uneveness. The use of the standard blade with a countersink angle of 90° was not sufficient for this special application in order to make all of the contour of the bore edge absolutely free of burrs. A special blade with a 60° countersink angle has been developed for this reason. This blade enabled a deeper deburring with the same deburr diameter. Hence, a constantly even broken edge breaking and a clean surface became reproduceable.

The customer is satisfied by the result and the achieved process capability. Having passed the approval procedure successfully, the tool has been released for serial production and is operated on two production line during 24 hours per day. The customer is excited about the reliability and the simple handling of the SNAP2 tool system.

The HEULE special tools are renowned for their simplicity and their process capability. Furthermore, all tools are designed consistently that no turning of the workpiece is required. The tools machine the front of the workpiece just as well as the back. The blades of the designed tool start to cut only when they touch the work piece. Tool repair and blade change are carried out easily and without any readjusting. These typical HEULE features guarantee extremely short machine down times.

Tool body: SNAP2/2.4/30

Blade: Special blade backward cutting only, GS cutting geometry, HM TiAlN coated

|

Cutting values deburring backward |

|

|

Speed |

3300 rpm |

|

Feed |

0.045 mm/rev. |

Cylinder head / Back Spot Facing Tool

HEULE has been reducing cycle times in the automotive industry successfully for over 30 years now. Today, car manufacturers ask for simple and process capable tool system. Terms like "time saving activities", "labor costs saving“ and "CIP continuous improvement process“ are common practice in the automotive industry.

The manufacture of countersinks, in particular screw head countersinks, are carried out mostly by back machining and are very time consuming. Either the workpiece is machined on the front surface which entails a turning of the workpiece. After the turning, it is evident that readjusting is inevitable and the time needed has tripled - or the machining is done backward. Most commonly a screw-on-type countersink or counterbore tool is used. The issue here is that - having to machine serveral hundreds of bores - all bores have to be approached individually because the countersink cap has to be fixed first every single time. Needless to mention that this takes a lot of time.

The high amount of time invested in each bore and the lacking process capability have led to rethinking this process.

| Through-hole |

Ø12.6 mm |

| Back Spot Facing backward |

Ø22.0 mm

|

| Material |

Aluminium Cast

|

The solution from HEULE reduces the processing time and improves the process capability. The workpiece is not to be moved in any case in order to keep the tolerance simply and safely.

By using the HEULE back spot facing tool the workpiece can be machined fully in one setup without the need for reclamping it or by adding an additional process step.

To operate the BSF tool an internal coolant with 20 bar pressure minimum is required.

| Working speed |

2000 rpm |

| Cutting speed |

140 m/min |

| Working feed |

0.05 mm/rev. |

The customer is very satisfied by the result and the achieved time savings. The high spindle speed reduces the fluttering of the blade due to the interrupted cut considerably.

Automotive Industry / Connecting Rod

HEULE has been reducing cycle times in the automotive industry successfully for over 30 years now. Today, car manufacturers ask for simple and process capable tool system. Terms like "time saving activities", "labor costs saving“ and "CIP continuous improvement process“ are common practice in the automotive industry

Our customer has been machining the connecting rods manually for years.

| Bore | Ø62.5 mm |

| Deburring size | Ø63.5 mm |

| Unevenness | 20° |

| Material | Forged steel |

The HEULE proposal stipulates a cassette solution with the COFA tool. The standard COFA cassette can be adapted easily to large bore diameters by using a customized tool holder. This method gives the freedom to use the standard cassette also for other deburring applications.

The burrs will be removed at the front and at the back without any problems. Due to the unevenness of the bore edge, the radial deburring will be slightly irregular.

The connecting rod is clamped on a undefined surface. As a result, the deburring surface is also undefined which is asking necessarily for a spring-guided deburring system that compensates for the variance.

The COFA blade does not hurt the already finished bore surface when traversing the hole. It is recommendable to apply low cutting values in order to allow the COFA blade to adapt to the contour.

Connecting rod / Main bore

| Working speed |

300 rpm |

| Working feed |

0.15 mm/rev. |

| Coolant |

External cooling |

Alloy wheels / valve hole

HEULE has been reducing cycle times in the automotive industry successfully for over 30 years now. Today, car manufacturers ask for simple and process capable tool system. Terms like "time saving activities", "labor costs saving“ and "CIP continuous improvement process“ are common practice in the automotive industry.

The production of bores and counterbores in the aluminium wheel is requiring 4 different tools. In addition, the production sequence includes a turning of the workpiece. Time and effort invested into the maintenance and the down time for the readjustment of the repaired tools are considerable. The high tool costs for the existing tools and the not assured process capablity were the reasons why the present production method has been questioned.

The new approach by HEULE proposes to unify all four existing tools into a single one. To do that HEULE combines two tool systems and their advantages in an ideal way. The new tool eliminates the time-consuming turning of the workpiece.

The customer is very pleased by the result and the achieved time savings. When combining different processes in one tool, it is important to adjust the working feed and also the speed of the countersinking and the chamfering. An internal cooling system is absolutely necessary to flush the chips away. HEULE is opting for an utmost sturdy tool design in order to avoid vibrations. Herefore, the given space sets out the framework for the dimensioning of this special combination tool.

The HEULE special tools are renowned for their simplicity and their process capability. Furthermore, all tools are designed consistently that no turning of the workpiece is required. The tools machine the front of the workpiece just as well as the back. The blades of the designed tool start to cut only when they touch the work piece. Tool repair and blade change are carried out easily and without any readjusting. These typical HEULE features guarantee extremely short machine down times.

Alloy wheel / Valve hole bore (forward and backward machining of the wheel)

Tool body: SNAP5 VEX-P Special tool

Blade: SNAP5 Ø11.6 DLC / GH-Q-M-15547 backward cutting only

WSP: Platte 30° aus Hartmetall beschichtet

| Drilling VEX-S | Chamfering SNAP |

| Speed: S = 2‘750 U/miN | Speed: S = 2‘750 U/min |

| Feed: F = 550mm/min | Feed: F = 450mm/min |