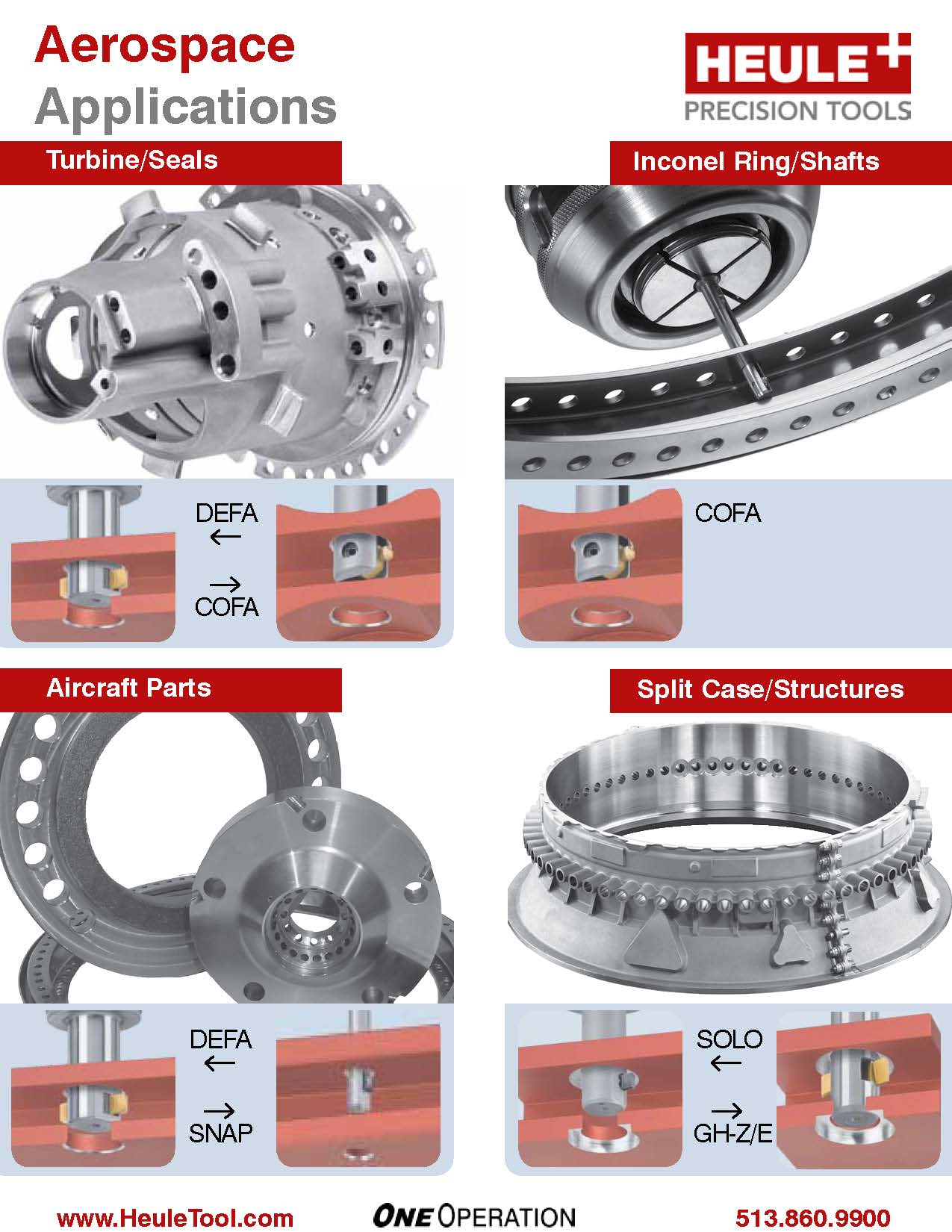

E-Catalog > HEULE PRECISION TOOLS > COFA - Universal Deburring Tool สำหรับลบครีบชิ้นงานทั้งผิวงานที่โค้งและแบบเรียบ

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- HEULE PRECISION TOOLS

- สินค้า, ผลิตภัณฑ์

Product Detail :

The COFA deburring tool removes burrs from the front and back of a drilled through hole without stopping or reversing the spindle. Whether you are deburring a flat surface or an irregular surface, the edge break is always even and consistent.

COFA's patented design uses a completely unique TiN coated carbide blade that allows for faster feeds and speeds and provides exceptionally long tool life. The action of the blade cuts a smooth tapered edge break from 0.010-0.030" based on the tool size.

COFA tools are available from stock for immediate delivery in sizes from 0.080" to 1.614" (2mm to 41mm). A cassette option is available for larger holes.

COFA - Universal Deburring Tool for Elliptical Holes and Irregular Parts

|

||||||||||||

|

The COFA deburring tool removes burrs from the front and back of a drilled through hole without stopping or reversing the spindle. Whether you are deburring a flat surface or an irregular surface, the edge break is always even and consistent. COFA's patented design uses a completely unique TiN coated carbide blade that allows for faster feeds and speeds and provides exceptionally long tool life. The action of the blade cuts a smooth tapered edge break from 0.010-0.030" based on the tool size. COFA tools are available from stock for immediate delivery in sizes from 0.080" to 1.614" (2mm to 41mm). A cassette option is available for larger holes. |

||||||||||||

|

||||||||||||

|

Description

|

||||||||||||

|

||||||||||||

|

1. Tool body 2. Roll Pin 3. Bending spring

4. Fixing strip 5. Cap screw 6. COFA blade |

||||||||||||

|

||||||||||||

| Application Examples | ||||||||||||

|

|

|

|

||||||||||

COFA and MicroCOFA

|

|

||||||||||||||||||||||||||||||||

SNAP and MicroSNAP

|

|

|

SNAP and MICROSNAP • Production front and back deburring and chamfering. |

|

||

|

High Quality Consistent Chamfers: The SNAP blades are ground with a patented geometry developed by Heule toproduce quality chamfers and eliminate secondary burrs. Different chamfer sizes can be achieved by selecting a different blade. There is no need for adjustments or operator intervention. |

|

|

How Does the SNAP Tool Work? |

||

|

|

||

COFA in Cast Iron:

This cast iron valve body is being deburred with the COFA deburring tool. The manufacturer is running the tool at 1400 rpm with a feed rate of 0.010ipr. The reported insert life is 17,000+ parts

COFA in Steel

This steel clevice is being deburred with the COFA deburring tool. The manufacturer is running the tool at 180SFM and 0.010ipr. Blade life is approximately 3,000-4,000 holes.