E-Catalog > PML-PAL Precision Air Chuck > Custom Solution Fixture

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- PML-PAL Precision Air Chuck

- สินค้า, ผลิตภัณฑ์

Product Detail :

Custom Solution Fixture

The following fixture is a complete custom-made solution that was designed for an automotive customer. This state-of-the-art fixture has several important features that PML-PAL offers in order to boost operation cycle efficiency.

The advantage of using a precision air chuck fixture is the ability to work on multiple work pieces simultaneously, hence cutting cycle time substantially (tool changing time saved is roughly 75%). Using our safe and reliable fixture enables easy installation and set-up, quick and easy loads and unloads of the work pieces, and most importantly, a high level of accuracy.

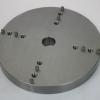

The fixture includes solid aluminum plate base, four (4) PML-PAL 150 dia. stationary precision air chucks, custom hardened top jaws, height stoppers, orientation pins, compact and hidden air tube layout, and a safety stop valve for each chuck. Hosing layout is routed under the plate for the chuck’s jaws actuation.

This page presents some of the PML-PAL engineering, design, and manufacturing capabilities. The PML-PAL team works closely with its customers in order to come up with a tailored fit. This customized fixture consolidates five operations into one for this customer and cuts their cycle time by more than 70%. Please review the photos and the explanation to learn more about the available features.

General view of the fixture

Close up view of the custom air chuck including: orientation pin, custom hardened top jaws, and height reference stoppers.

Above is a view of the chuck with the customer’s work piece. The customer has provided us with samples of a work piece for orientation and height testing purposes, as well as for trial operations of actual milling as part of fixture approval process before shipping.

Each air chuck has its own individual actuation valve. Notice the plastic fitting on each air tube going into the aluminum base. This fitting keeps dirt and metal swarf from penetrating the area between the aluminum base and the machine table.

This is the fixture bottom view. This photo shows the chuck stop valve. The stop valve is a safety feature; it captures the air pressure in the chuck in case of air supply interruption or compressor malfunction. The valve keeps the pressure in clamping position until manual release.

Video of the fixture on a CNC machining center is available @ this page

The above is a demonstration of a custom-made PML-PAL fixture. Our fixtures can be tailored to most unique situations or challenges. Any chuck of any diameter size or number of top jaws can be mounted on a fixture.

Custom Fixture Stationary Air Chucks

Situation

An automotive customer contacted PML-PAL Engineering revealing that he currently manufactures certain part running three milling operations on three machines making one part at the time. Total operating time for each work-piece was around 12 minutes including manual load/unload and manual set up on each machine. The customer asked to help to streamline his production.

Solution

PML-PAL worked closely with the customer to come up with an agreeable solution given a few working environment constraints. We designed an Aluminum fixture to hold four stationary precision air chucks model 150-3-2.5 ST. Each chuck includes three custom jaws, height stoppers, and an orientation pin. Each chuck has its own operating air valve for a quick clamping and release. Each chuck has a safety air valve as well in case of air supply interruption (more information is available @ custom fixture

Results

The customer effortlessly installed the fixture on his CNC machining center. Now the machine runs four work pieces simultaneously. It is easy to load, orient, and unload the parts on each chuck. All operations are done on one machine. Bottom line….the cycle time is now less than 8 minutes for four (4) work pieces down from 48 minutes, savings of over 80%.