E-Catalog > WTO-DRIVEN TOOL > WTO-DRIVEN TOOL

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- WTO-DRIVEN TOOL

- สินค้า, ผลิตภัณฑ์

Product Detail :

Products

Our current product range covers a large amount of innovative and technically well-engineered solutions of static and driven precision toolholders.

Those are available for all current Turning Centers, Swiss Type Turning Centers, Multiple Spindle Turning Centers and Cycle Controlled Lathes.

Individual customer specific engineered solutions complete our wide standard program.

Our products are made with highest precision and quality without compromises.

|

|

|

||

Turning Centers |

Swiss Type Turning Centers |

Multiple Spindle Turning Centers |

||

| more | more | more | ||

|

|

|

||

Cycle Controlled Lathes |

Gear Hobbing |

Thread Whirling |

||

| more | more |

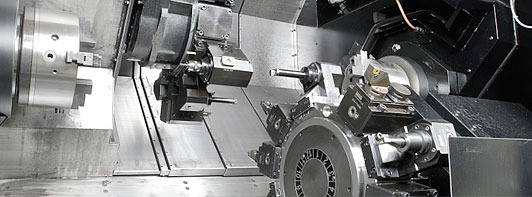

Turning Centers

Modern Turning Centers are using powerful turret drive motors to achieve high cutting performance for drilling and milling operations. With a WTO driven precision tool you are able to use the full power range of your machine. We offer solutions which are optimized for your machine type.

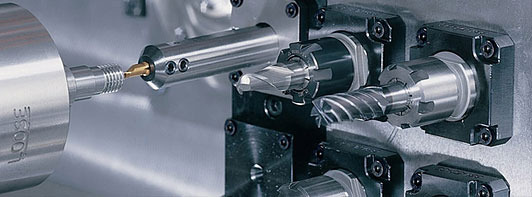

Swiss Type Turning Centers

WTO has developed a large product range of static and driven toolholders for Swiss Type Turning Centers.

Our toolholders are optimal designed for each machine that you can achieve higher productivity.

We are designing and manufacturing complete sliding units and tool holding systems for machine tool manufacturers.

Besides the standard versions for axial and radial operations we are offering application specific driven toolholders to increase your productivity:

- Thread whirling units

- Gear hobbing units

- Adjustable angle drill/milling units

- High speed drill/milling units

- Deep hole drilling units up to 200 bar coolant pressure

- Slitting saw units

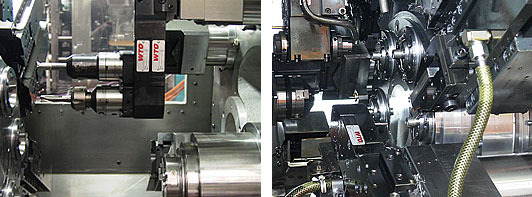

Multiple Spindle Turning Centers

Multiple Spindle Turning Centers are high productive machines we are offering a wide product range for as well customized solutions. With WTO toolholders you are able to manufacture complex work pieces with high productivity.

Our large program contains:

Static toolholders for turning operations

- Modular and monoblock toolholders for axial and radial operations

Driven toolholders

- Drill-/Milling units for axial and radial operations

- Adjustable angle drill/milling units

- Drill-/Milling units with speed increase or torque increase

- Deep hole drilling units up to 200 bar coolant pressure

- Gear hobbing units

Aggregates

- Stroke increaser

- Linear slide turret

- Cross slide turret

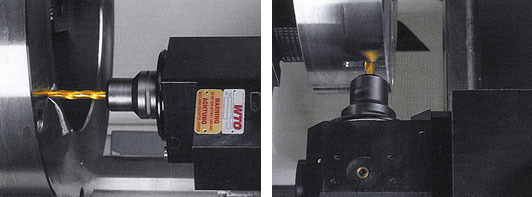

Cycle Controlled Lathes

You don't need to miss complete manufacturing of your part when using cycle controlled lathes. WTO has developed a flexible tool holding system for these machines which enables using driven toolholders for drilling and milling besides the classic turning operation.

The flexible tool holding system uses a basic toolholder block with quick change system which will be installed on the cross slide of the lathe by the machine tool manufacturer.

The basic toolholder block is equipped with an external drive motor for the driven toolholders. Toolholders for turning operations as well driven toolholders can be manually clamped in the same quick chance system

Advantages of the WTO tool holding system:

- Drilling, milling and tapping also out off the work piece center

- High flexibility and fast tool change using quick change systems

- Standard Basic toolholder blocks for VDI or Coromant Capto®

- Different tooling systems for most Cycle Controlled Lathes available