E-Catalog > จำหน่าย Hob Cutters and Shaving Cutters > จำหน่าย Hob Cutters and Shaving Cutters

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- จำหน่าย Hob Cutters and Shaving Cutters

- สินค้า, ผลิตภัณฑ์

Product Detail :

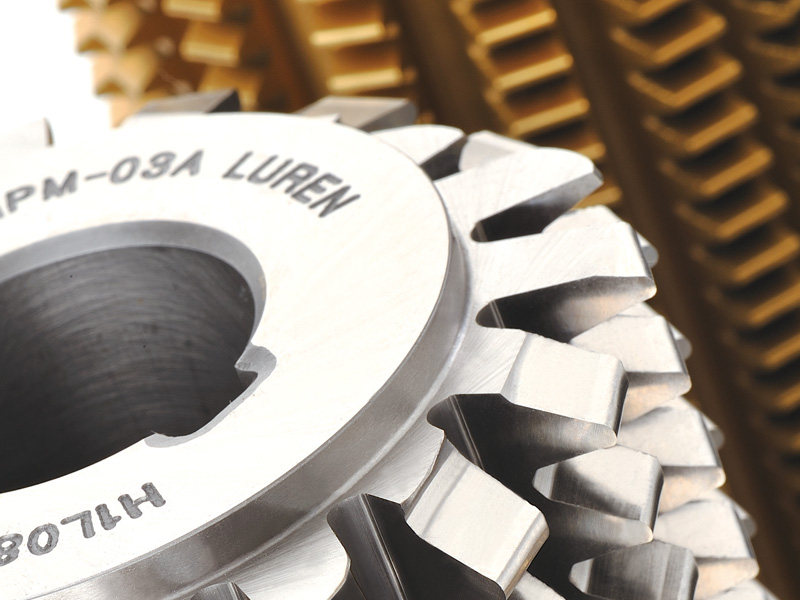

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

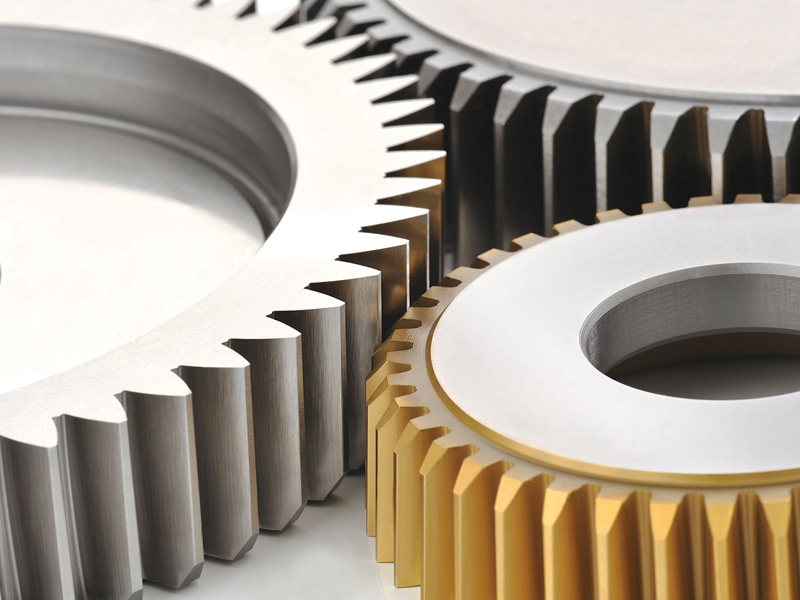

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

Module 0.5-10 (DP 50.8– 2.54 ), single/multi starts, Straight/ helix angle for any kind of hobs, and suitable for dry and wet cutting.

- Hobs: Bore/ shank type

- OD: 25-160mm (0.984 – 6.299 inch), Length: less than 220mm (8.66 inch)

- Benefit of Dry cutting: Green environment Suitable for high speed cutting

- Types: Gear, worm gear, rack, special form.

- Precision: A, AA (DIN3968)

- Patterns: Finishing, Roughing, Pre-shaving, Pre-grinding

- Material: High Speed steel (HSS)- Conventional or powder metallurgy

- Coating: TiN, TiCN, TiAlN, Alcron

Module 0.5~2.5 Triple life time more than conventional HSS cutter 60%~80% time saving per piece for gear manufacture. Supporting high hardness (HRC60), high ductility & toughness gear cutting. Time saving with optimized hobbing process for less needed cutter change. Providing services of recoating & profile grinding. Wide size range for choices.

- Precision : Class A, AA, AAA (DIN 3968).

- Outside Dia. : 25~75mm.

- Patterns : Skiving, Finishing.

- Coating : TiAlN, Alcrona.

- Type : Conventional, Diagonal, Plunge, Underpass.

- Module : 1~8.

- Outside Dia. : 59~250 mm.

- Width : 18~68 mm.

- Cutter Helix Angle ≦30°.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

We offer customized profile for shaper cutters, such as protuberance and semi-topping.

- Module : 0.5~6.

- Types : DISC, BELL, SHANK.

- Precision : CLASS A, AA (DIN 1829).

- Length : 30~200 mm.

- Precision: A, AA (DIN3968).

- Pattern : Finishing, Pre-shaving, Pre-grinding.

- Material : High Speed Steel (HSS), conventional or powder metallurgy.

- Coating : TiN, TiCN, TiAlN, Alcrona.

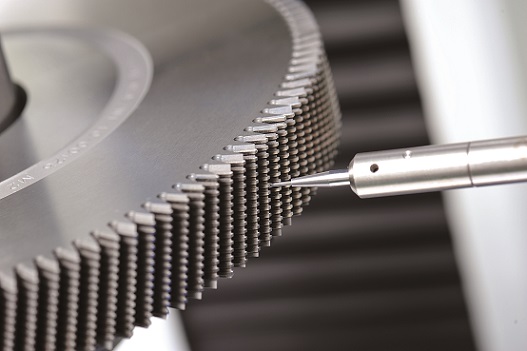

We offer master gears for mesh testing, gear measuring and correction, the result corresponds to DIN 3970, JIS B 1751 or any customer’s requirement. Besides, it is component to use special materials to ensure the quality and tool life. Master gears are used in gear meshing and measuring, based on any index and graph or other instruments to confirm that master gears and gears mesh together. Master gears also apply for aeronautical and automobile industries.

- Module : 0.5~8.

- Outside Dia. : 30~250 mm.

- Helix Angle : ≦35°.

- Precision : DIN 4 or M 0.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

- Coating : TiN.

Matrix (since Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (since Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (since Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

Module 0.5-10 (DP 50.8– 2.54 ), single/multi starts, Straight/ helix angle for any kind of hobs, and suitable for dry and wet cutting.

- Hobs: Bore/ shank type

- OD: 25-160mm (0.984 – 6.299 inch), Length: less than 220mm (8.66 inch)

- Benefit of Dry cutting: Green environment Suitable for high speed cutting

- Types: Gear, worm gear, rack, special form.

- Precision: A, AA (DIN3968)

- Patterns: Finishing, Roughing, Pre-shaving, Pre-grinding

- Material: High Speed steel (HSS)- Conventional or powder metallurgy

- Coating: TiN, TiCN, TiAlN, Alcron

Module 0.5~2.5 Triple life time more than conventional HSS cutter 60%~80% time saving per piece for gear manufacture. Supporting high hardness (HRC60), high ductility & toughness gear cutting. Time saving with optimized hobbing process for less needed cutter change. Providing services of recoating & profile grinding. Wide size range for choices.

- Precision : Class A, AA, AAA (DIN 3968).

- Outside Dia. : 25~75mm.

- Patterns : Skiving, Finishing.

- Coating : TiAlN, Alcrona.

- Type : Conventional, Diagonal, Plunge, Underpass.

- Module : 1~8.

- Outside Dia. : 59~250 mm.

- Width : 18~68 mm.

- Cutter Helix Angle ≦30°.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

We offer customized profile for shaper cutters, such as protuberance and semi-topping.

- Module : 0.5~6.

- Types : DISC, BELL, SHANK.

- Precision : CLASS A, AA (DIN 1829).

- Length : 30~200 mm.

- Precision: A, AA (DIN3968).

- Pattern : Finishing, Pre-shaving, Pre-grinding.

- Material : High Speed Steel (HSS), conventional or powder metallurgy.

- Coating : TiN, TiCN, TiAlN, Alcrona.

We offer master gears for mesh testing, gear measuring and correction, the result corresponds to DIN 3970, JIS B 1751 or any customer’s requirement. Besides, it is component to use special materials to ensure the quality and tool life. Master gears are used in gear meshing and measuring, based on any index and graph or other instruments to confirm that master gears and gears mesh together. Master gears also apply for aeronautical and automobile industries.

- Module : 0.5~8.

- Outside Dia. : 30~250 mm.

- Helix Angle : ≦35°.

- Precision : DIN 4 or M 0.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

- Coating : TiN.

Matrix (since Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (since Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (since Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

Module 0.5-10 (DP 50.8– 2.54 ), single/multi starts, Straight/ helix angle for any kind of hobs, and suitable for dry and wet cutting.

- Hobs: Bore/ shank type

- OD: 25-160mm (0.984 – 6.299 inch), Length: less than 220mm (8.66 inch)

- Benefit of Dry cutting: Green environment Suitable for high speed cutting

- Types: Gear, worm gear, rack, special form.

- Precision: A, AA (DIN3968)

- Patterns: Finishing, Roughing, Pre-shaving, Pre-grinding

- Material: High Speed steel (HSS)- Conventional or powder metallurgy

- Coating: TiN, TiCN, TiAlN, Alcron

Module 0.5~2.5 Triple life time more than conventional HSS cutter 60%~80% time saving per piece for gear manufacture. Supporting high hardness (HRC60), high ductility & toughness gear cutting. Time saving with optimized hobbing process for less needed cutter change. Providing services of recoating & profile grinding. Wide size range for choices.

- Precision : Class A, AA, AAA (DIN 3968).

- Outside Dia. : 25~75mm.

- Patterns : Skiving, Finishing.

- Coating : TiAlN, Alcrona.

- Type : Conventional, Diagonal, Plunge, Underpass.

- Module : 1~8.

- Outside Dia. : 59~250 mm.

- Width : 18~68 mm.

- Cutter Helix Angle ≦30°.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

We offer customized profile for shaper cutters, such as protuberance and semi-topping.

- Module : 0.5~6.

- Types : DISC, BELL, SHANK.

- Precision : CLASS A, AA (DIN 1829).

- Length : 30~200 mm.

- Precision: A, AA (DIN3968).

- Pattern : Finishing, Pre-shaving, Pre-grinding.

- Material : High Speed Steel (HSS), conventional or powder metallurgy.

- Coating : TiN, TiCN, TiAlN, Alcrona.

We offer master gears for mesh testing, gear measuring and correction, the result corresponds to DIN 3970, JIS B 1751 or any customer’s requirement. Besides, it is component to use special materials to ensure the quality and tool life. Master gears are used in gear meshing and measuring, based on any index and graph or other instruments to confirm that master gears and gears mesh together. Master gears also apply for aeronautical and automobile industries.

- Module : 0.5~8.

- Outside Dia. : 30~250 mm.

- Helix Angle : ≦35°.

- Precision : DIN 4 or M 0.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

- Coating : TiN.

Matrix (since Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (since Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (since Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

Module 0.5-10 (DP 50.8– 2.54 ), single/multi starts, Straight/ helix angle for any kind of hobs, and suitable for dry and wet cutting.

- Hobs: Bore/ shank type

- OD: 25-160mm (0.984 – 6.299 inch), Length: less than 220mm (8.66 inch)

- Benefit of Dry cutting: Green environment Suitable for high speed cutting

- Types: Gear, worm gear, rack, special form.

- Precision: A, AA (DIN3968)

- Patterns: Finishing, Roughing, Pre-shaving, Pre-grinding

- Material: High Speed steel (HSS)- Conventional or powder metallurgy

- Coating: TiN, TiCN, TiAlN, Alcron

Module 0.5~2.5 Triple life time more than conventional HSS cutter 60%~80% time saving per piece for gear manufacture. Supporting high hardness (HRC60), high ductility & toughness gear cutting. Time saving with optimized hobbing process for less needed cutter change. Providing services of recoating & profile grinding. Wide size range for choices.

- Precision : Class A, AA, AAA (DIN 3968).

- Outside Dia. : 25~75mm.

- Patterns : Skiving, Finishing.

- Coating : TiAlN, Alcrona.

- Type : Conventional, Diagonal, Plunge, Underpass.

- Module : 1~8.

- Outside Dia. : 59~250 mm.

- Width : 18~68 mm.

- Cutter Helix Angle ≦30°.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

We offer customized profile for shaper cutters, such as protuberance and semi-topping.

- Module : 0.5~6.

- Types : DISC, BELL, SHANK.

- Precision : CLASS A, AA (DIN 1829).

- Length : 30~200 mm.

- Precision: A, AA (DIN3968).

- Pattern : Finishing, Pre-shaving, Pre-grinding.

- Material : High Speed Steel (HSS), conventional or powder metallurgy.

- Coating : TiN, TiCN, TiAlN, Alcrona.

We offer master gears for mesh testing, gear measuring and correction, the result corresponds to DIN 3970, JIS B 1751 or any customer’s requirement. Besides, it is component to use special materials to ensure the quality and tool life. Master gears are used in gear meshing and measuring, based on any index and graph or other instruments to confirm that master gears and gears mesh together. Master gears also apply for aeronautical and automobile industries.

- Module : 0.5~8.

- Outside Dia. : 30~250 mm.

- Helix Angle : ≦35°.

- Precision : DIN 4 or M 0.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

- Coating : TiN.

Matrix (since Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (since Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (since Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

Module 0.5-10 (DP 50.8– 2.54 ), single/multi starts, Straight/ helix angle for any kind of hobs, and suitable for dry and wet cutting.

- Hobs: Bore/ shank type

- OD: 25-160mm (0.984 – 6.299 inch), Length: less than 220mm (8.66 inch)

- Benefit of Dry cutting: Green environment Suitable for high speed cutting

- Types: Gear, worm gear, rack, special form.

- Precision: A, AA (DIN3968)

- Patterns: Finishing, Roughing, Pre-shaving, Pre-grinding

- Material: High Speed steel (HSS)- Conventional or powder metallurgy

- Coating: TiN, TiCN, TiAlN, Alcron

Module 0.5~2.5 Triple life time more than conventional HSS cutter 60%~80% time saving per piece for gear manufacture. Supporting high hardness (HRC60), high ductility & toughness gear cutting. Time saving with optimized hobbing process for less needed cutter change. Providing services of recoating & profile grinding. Wide size range for choices.

- Precision : Class A, AA, AAA (DIN 3968).

- Outside Dia. : 25~75mm.

- Patterns : Skiving, Finishing.

- Coating : TiAlN, Alcrona.

- Type : Conventional, Diagonal, Plunge, Underpass.

- Module : 1~8.

- Outside Dia. : 59~250 mm.

- Width : 18~68 mm.

- Cutter Helix Angle ≦30°.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

We offer customized profile for shaper cutters, such as protuberance and semi-topping.

- Module : 0.5~6.

- Types : DISC, BELL, SHANK.

- Precision : CLASS A, AA (DIN 1829).

- Length : 30~200 mm.

- Precision: A, AA (DIN3968).

- Pattern : Finishing, Pre-shaving, Pre-grinding.

- Material : High Speed Steel (HSS), conventional or powder metallurgy.

- Coating : TiN, TiCN, TiAlN, Alcrona.

We offer master gears for mesh testing, gear measuring and correction, the result corresponds to DIN 3970, JIS B 1751 or any customer’s requirement. Besides, it is component to use special materials to ensure the quality and tool life. Master gears are used in gear meshing and measuring, based on any index and graph or other instruments to confirm that master gears and gears mesh together. Master gears also apply for aeronautical and automobile industries.

- Module : 0.5~8.

- Outside Dia. : 30~250 mm.

- Helix Angle : ≦35°.

- Precision : DIN 4 or M 0.

- Material : High Speed Steel(HSS), conventional or powder metallurgy.

- Coating : TiN.

Matrix (since Luren) was established in 1994. In these years, it developed the designing software, machine tools, gear cutters, such as, hobs, carbide hobs and shaving cutters, master gears and maintenance for the cutters.

Matrix (since Luren) has integrated a producing system to provide the high quality products because offer a 100% perfection products is our goal. We are not only strict control the production line, but also every product is inspected tightly. We keep to improve the producing system to face more challenges and various requests from the customers. For instance, Matrix (since Luren) has developed many kinds of grinding and resharpening machines to enhance the producing efficiency.

We always offer the best quality of gear cutters; widespread range of products, and fastest delivery date to satisfied the customer's needs.

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER GEAR HOBS มีดกัดเฟือง HOB CUTTER หรือ Gear hobs

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

HOBS

Gear Hobs

GEAR SHAVING CUTTERS

จำหน่ายมีดกัดเฟือง Gear Hob CUTTER Gear Hobbing

gear hob, skving cutter, shaper cutter gear hobbing tools

Gear Hobbing