Product Detail :

Knife Sharpening

Learn how to sharpen knives like a pro - quick and easy!

- Knowledge

- How to Sharpen Your Tools

- Knife Sharpening

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

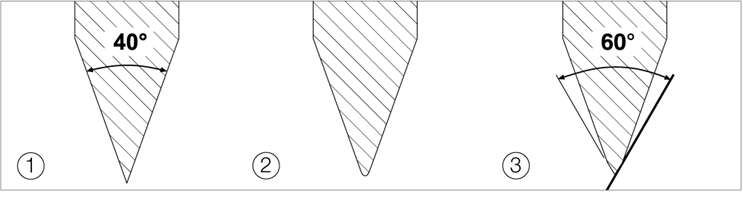

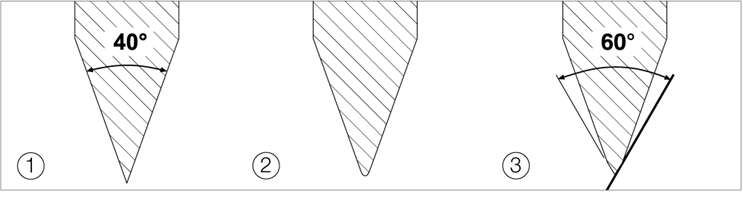

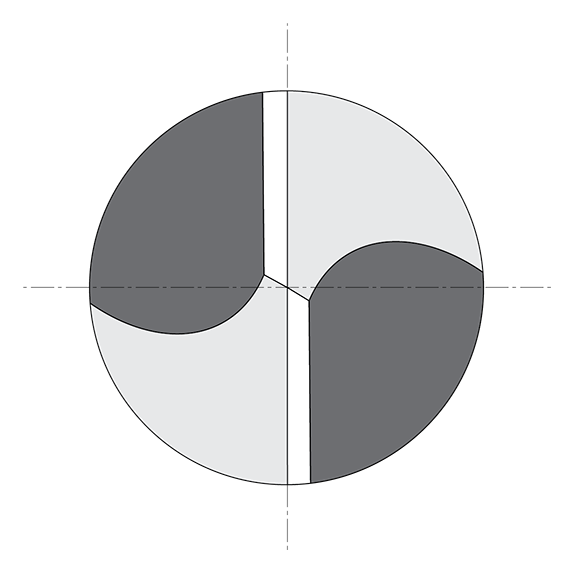

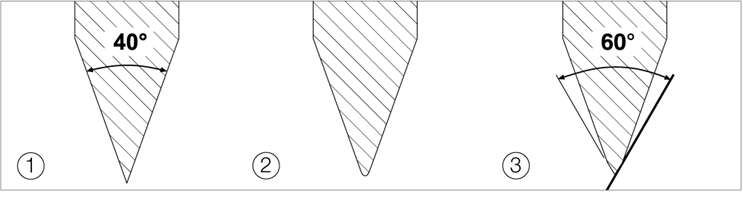

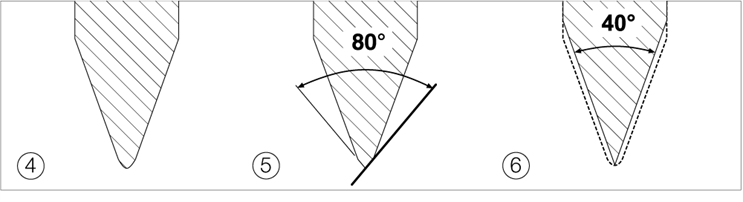

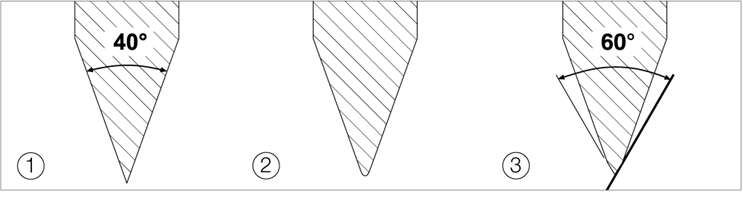

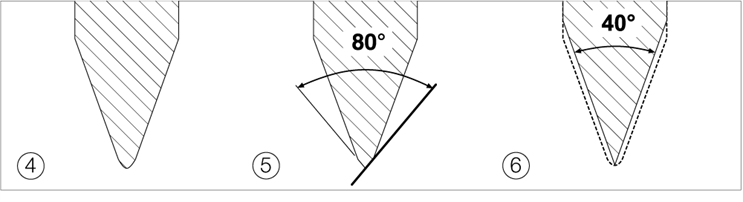

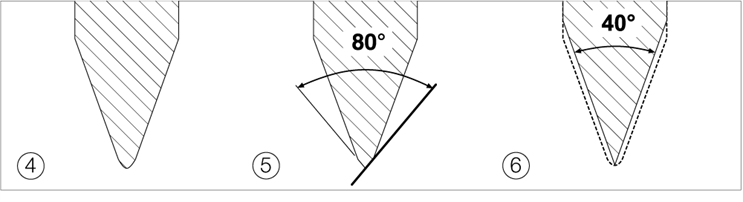

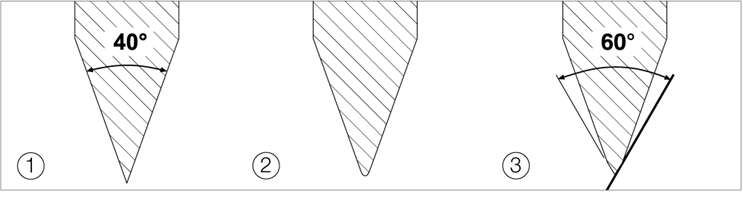

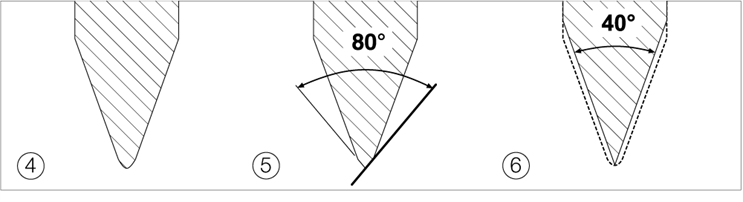

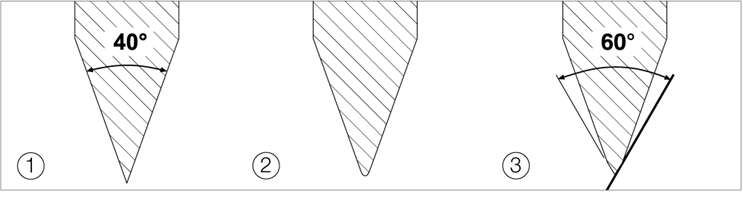

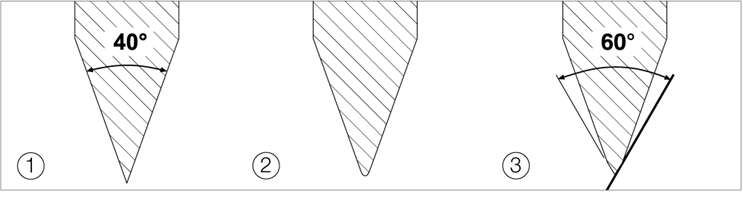

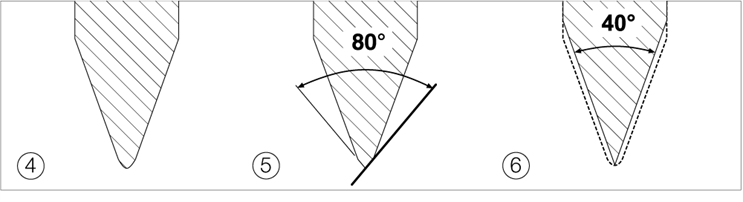

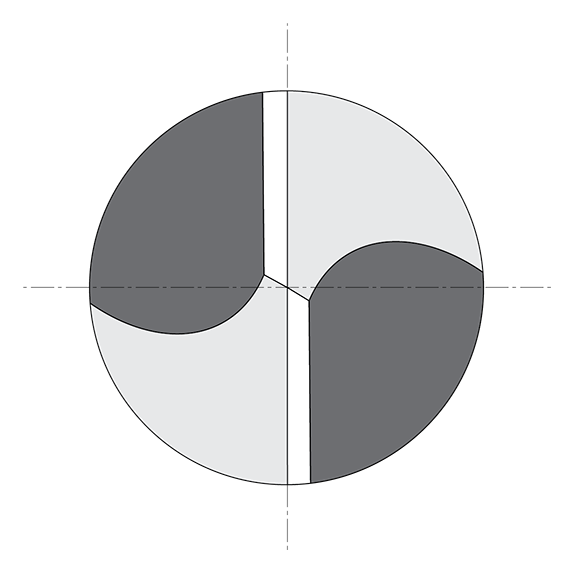

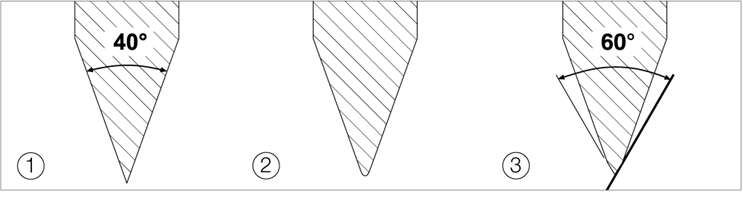

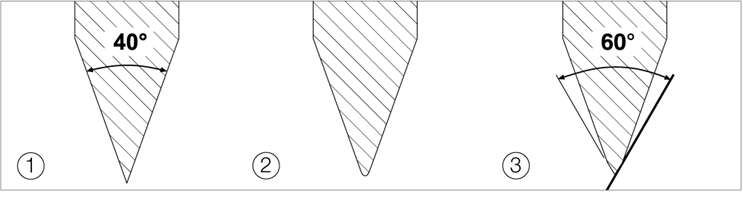

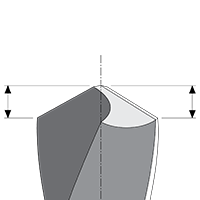

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

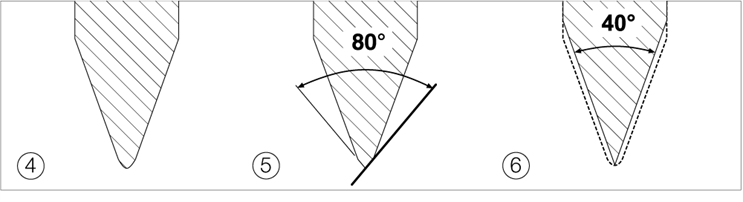

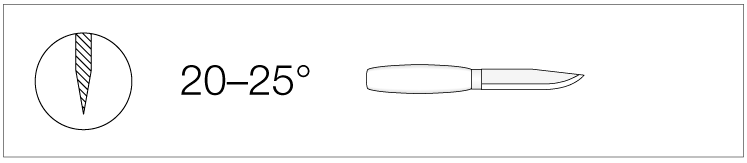

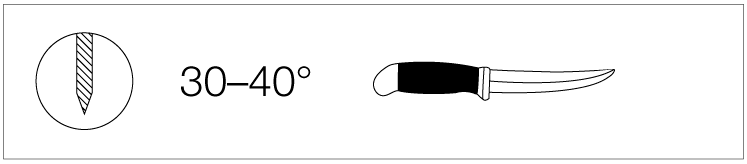

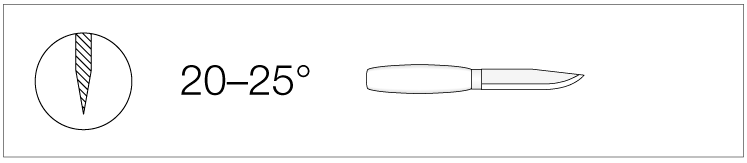

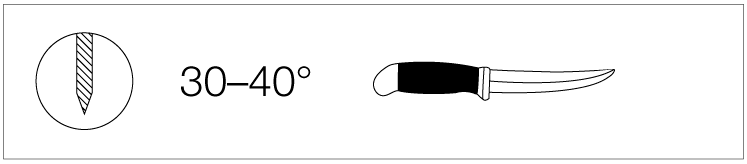

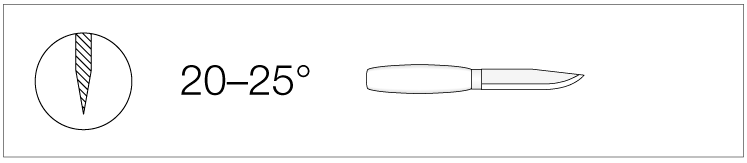

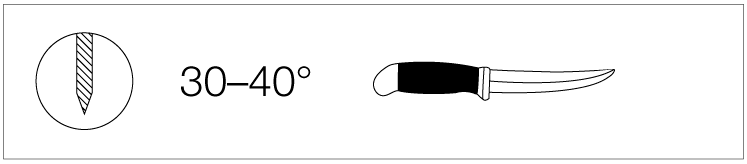

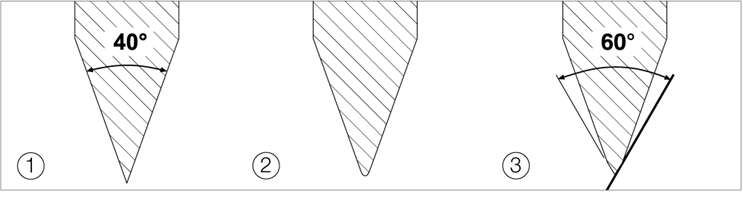

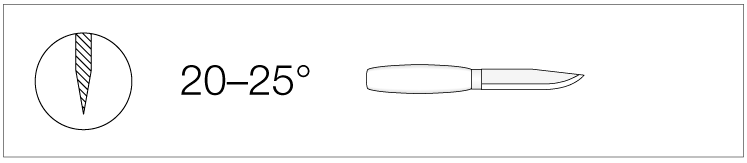

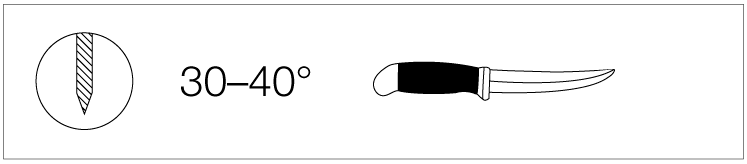

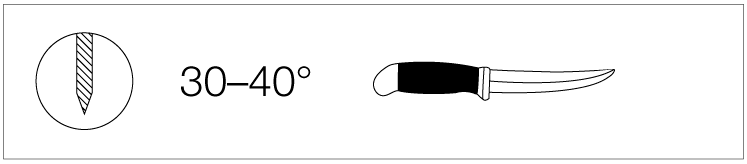

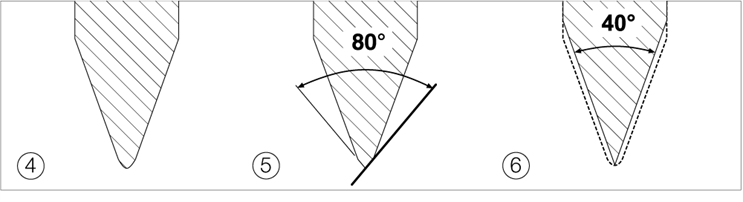

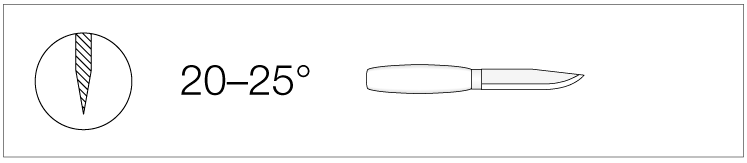

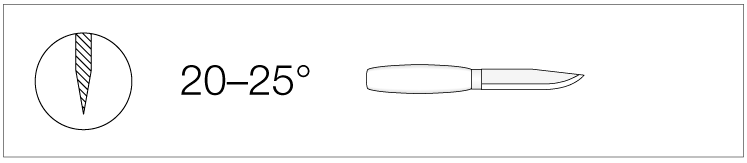

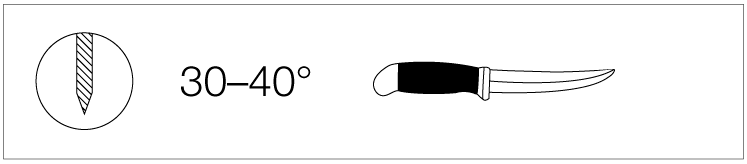

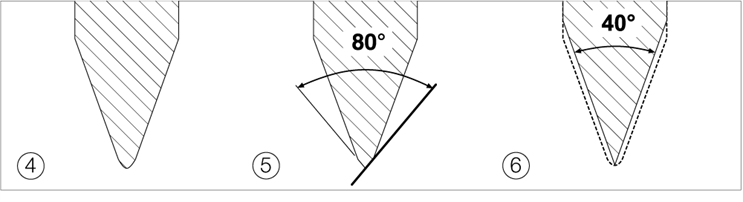

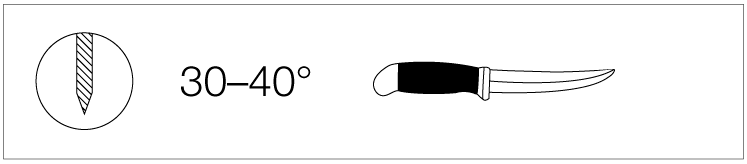

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

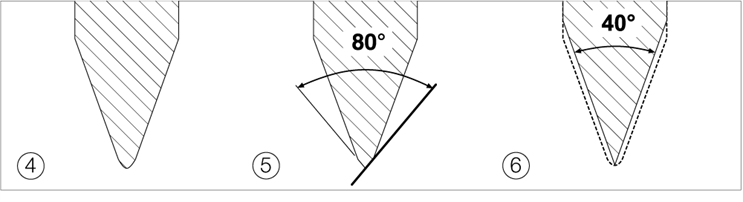

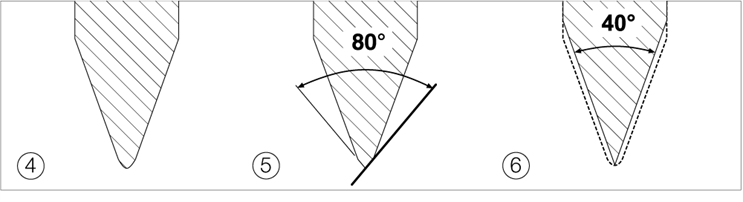

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

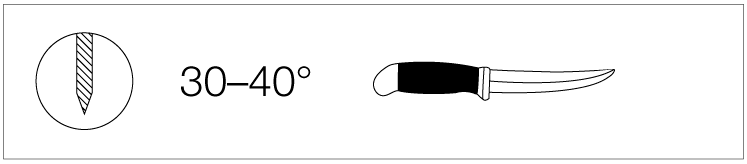

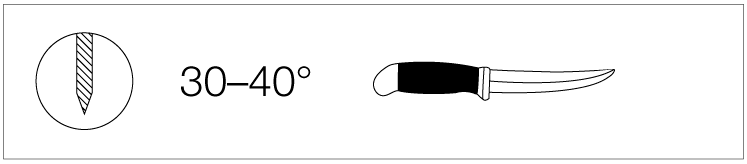

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

How to sharpen your tools

For professional crafts, hobby or culinary use

Sharpen your knives and other tools to a durable and razor-sharp result. Tormek's sharpening machines provides you with the possibility to sharpen different knives and tools for professional and hobby use.

Woodcarving Tools

Sharp tools cuts cleaner

Hunting & Outdoor Tools

Sharpen knives and axes for hunting and outdoor

Knife Sharpening for the Commercial Kitchen

Achieve a more efficient kitchen with sharp knives

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

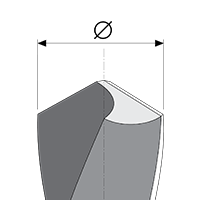

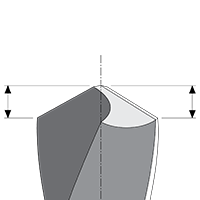

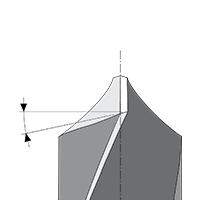

Give New Life to Your Drill Bits

With the patented DBS-22 Drill Bit Sharpening Attachment you can sharpen your drill bits with the highest precision. The optimal point and clearance angles can be set according to each drilling requirement, which depends upon the drill size and material. You can completely restore worn drills as well as broken drills to a perfect shape.

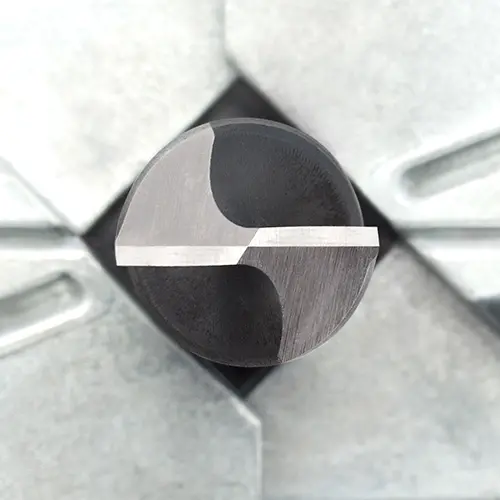

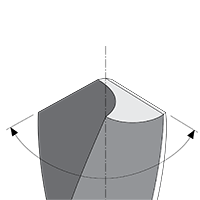

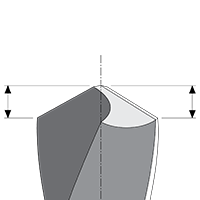

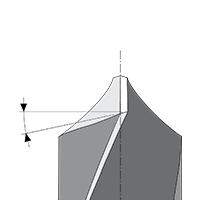

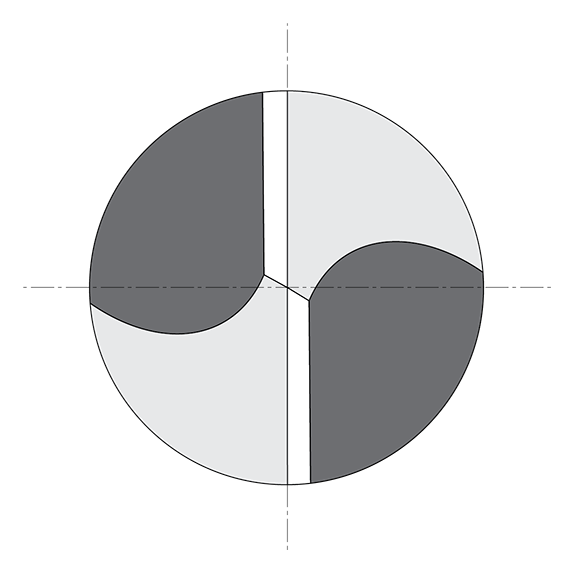

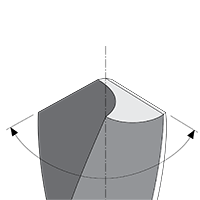

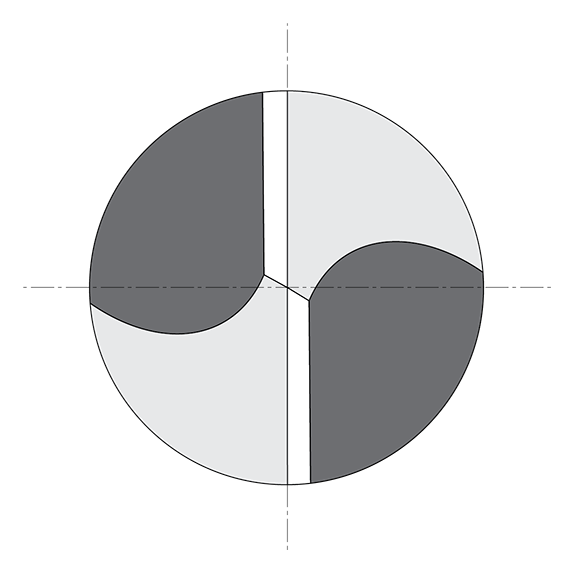

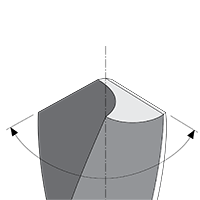

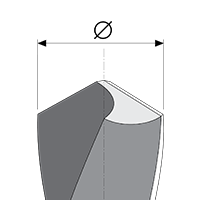

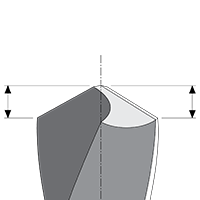

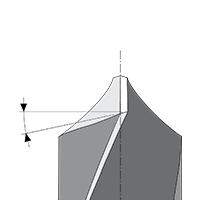

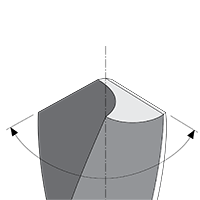

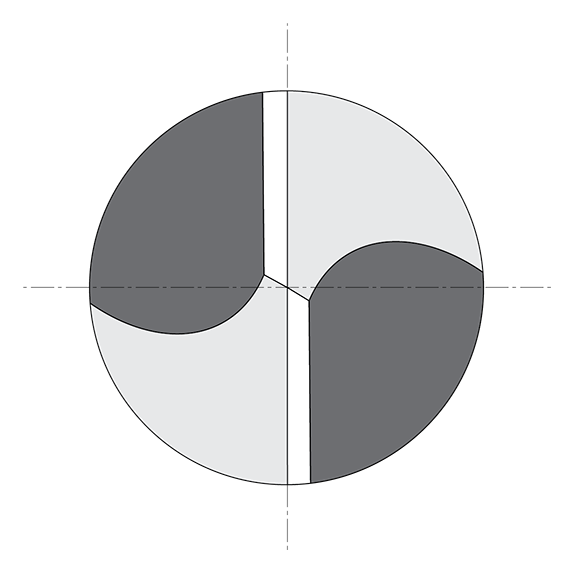

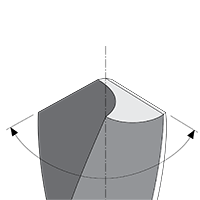

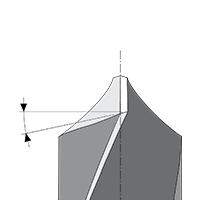

A Better Cutting Geometry

When you sharpen your drill bits with the DBS-22 Drill Bit Sharpening Attachment, you create a four-facet point which gives the ideal cutting performance since the chisel edge gets a point instead of being almost flat as on many drills. A four-facet point will not walk and the thrust force required is considerably reduced compared to a conventional cone point drill.

A precision sharpened four-facet point generates less heat and the life of the drill is therefore also prolonged. Independent tests show that a Tormek sharpened drill lasts up to 4 times longer than a brand new conventional drill bit¹.

¹Uddeholm Tooling AB, 2010. 15 mm deep holes were drilled in toughened steel with 6 mm drills. With rotation speed 1,326 rpm and 0.15 mm feed per rotation, the Tormek sharpened drills lasted on average 327 holes while the new drills with an s-shaped point lasted 72 holes.

The drill bit gets a four-facet point that doesn't walk. Bores a round and straight hole with close tolerances.

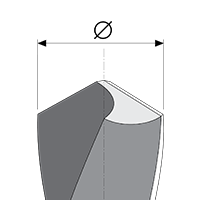

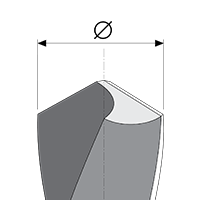

Sharpens all point angles

It can be set at any angle between 90° and 150°.

Sharpens drill bits from 3–22 mm

One and the same drill holder copes with all sizes between 3 mm (⅛") and 22 mm (⅞"). No change of chuck required.

Always equal cutting edges

The two cutting edges are sharpened symmetrically and work in perfect unison which prolongs the life of the drill.

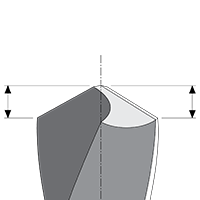

Always the right clearance angle

The optimal clearance angle can be set according to each drilling requirement to 7°, 9°, 11° or 14°.

Drill Bit Sharpening With the DBS-22 Drill Bit Sharpening Attachment

Pontus and Sébastien from Tormek show you how to sharpen drill bits using the DBS-22 Drill Bit Sharpening Attachment. There's probably quite a few of us that has a bunch of dull drill bits laying around in the workshop. You'll be amazed at the incredible difference of a razor sharp, four-facet point drill compared to a conventional one. We show you how to create a four-facet point for ideal cutting performance.

The Four-facet Point

The four-facet point achieved with the DBS-22 Drill Bit Sharpening Attachment is very beneficial compared to a conventional drill bit point. It considerably decreases the force required on the core of the drill, i.e the chisel edge, which reduces the heat development and permits an increased force to the cutting edges. This gives the drill a dramatic improvement in cutting performance.

Both cutting edges are sharpened to an exact equal length and symmetrically. The four-facet geometry and the high precision sharpening makes the drill work efficiently and the life of the drill bit is considerably prolonged. The point geometry and precision sharpening is also crucial to achieve an exact and circular hole.

Choose the right point angle

Drill bits usually have a point angle of 118° or 130°. Hardened steel

and stainless steel require larger point angles. Also aluminium is best

drilled with a larger point angle. When drilling plexiglass, the risk of

cracks when the drill goes through the material is reduced with a

larger point angle. Centering drills usually have a 90° point angle.

Choose the right clearance angle

The choice of clearance angle is crucial to the cutting performance

and duration of the drill. The optimal clearance angle depends both

on the drill diameter and the material to be drilled. A harder material

requires a drill with a smaller clearance angle while a softer material

can have a larger angle. Standard drills have a clearance angle of

11° and a 118° point angle which work well for most drilling work.

How do you know if the steel has become overheated when using a dry grinder?

Overheating of the steel is often not noticeable, but the consequences are that the drill will dull rapidly and may even break. Unlike conventional drill bit sharpeners, Tormek sharpens with water cooling which is gentle on the steel.

Start with sharp tools

If you are a woodturner and have not yet discovered Tormek, there is a big chance you will be surprised to see how big a difference a really well sharpened edge can do to your final result at the lathe. As you know, the sense of control and flow at the lathe starts with sharp tools.

- Sharper woodturning tools gives better results, faster.

- Smart jigs and accessories makes sharpening incredibly fast and easy, even for tools with a complex geometry and unusual profiles.

- Water-cooled sharpening at low rpm never damage your edge.

- Shaping and sharpening on a bench grinder is possible with the extensive Tormek jig system, but heat development risks damaging your tools if you're not careful.

- Sharpening vs shaping: When sharpening a tool you just touch up the edge of an existing shape to renew the sharpness.

- Sharpening vs shaping: When shaping a tool, you remove steel to get your desired shape and edge angle. You can do both shaping and sharpening on your Tormek.

- Simple honing on the inside of arched edges, such as the edge of a bowl gouge

- Unbeatable result, appreciated by professionals worldwide.

Sharpening woodturning tools on your Tormek - instruction video with Glenn Lucas

Glenn Lucas is one of the greatest woodturners in the world. He has been using the Tormek water-cooled sharpening system for many years. He even teaches sharpening during his courses External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

Sharpening Class - Woodturning tools

In this episode, Wolfgang and Sébastien from Tormek demonstrate how you sharpen tools for the woodturner; gouges, skews, parting tools, scrapers, cutters and more. We show you the methods for sharpening all these turning tools and how you achieve repeatable edges every time. This class is based on the jigs and accessories included in the TNT-808 Woodturner's Kit, which includes everything you need to sharpen and shape your woodturning tools.

Sharpen Less – Turn More!

The Tormek way of sharpening differs from other grinding methods like high-speed bench grinders and belt sanders. Tormek makes a clear distinction between shaping and sharpening. Once the tool is shaped to the right shape, you remove only a minimal amount of steel when sharpening – you just touch up the edge. An important benefit of the minimal steel removal is that the sharpening is fast, in addition, your precious tools will last much longer.

With the patented TTS-100 Turning Tool Setter every aspect of the set-up is simple and you can be sure to get the exact same shape of your tool every time you sharpen, regardless if the you have a grindstone that will get a smaller diameter over the years.

The high level of control in the sharpening process combined with a su

Knife Sharpening

Learn how to sharpen knives like a pro - quick and easy!

- Knowledge

- How to Sharpen Your Tools

- Knife Sharpening

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

How to sharpen your tools

For professional crafts, hobby or culinary use

Sharpen your knives and other tools to a durable and razor-sharp result. Tormek's sharpening machines provides you with the possibility to sharpen different knives and tools for professional and hobby use.

Woodcarving Tools

Sharp tools cuts cleaner

Hunting & Outdoor Tools

Sharpen knives and axes for hunting and outdoor

Knife Sharpening for the Commercial Kitchen

Achieve a more efficient kitchen with sharp knives

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

Give New Life to Your Drill Bits

With the patented DBS-22 Drill Bit Sharpening Attachment you can sharpen your drill bits with the highest precision. The optimal point and clearance angles can be set according to each drilling requirement, which depends upon the drill size and material. You can completely restore worn drills as well as broken drills to a perfect shape.

A Better Cutting Geometry

When you sharpen your drill bits with the DBS-22 Drill Bit Sharpening Attachment, you create a four-facet point which gives the ideal cutting performance since the chisel edge gets a point instead of being almost flat as on many drills. A four-facet point will not walk and the thrust force required is considerably reduced compared to a conventional cone point drill.

A precision sharpened four-facet point generates less heat and the life of the drill is therefore also prolonged. Independent tests show that a Tormek sharpened drill lasts up to 4 times longer than a brand new conventional drill bit¹.

¹Uddeholm Tooling AB, 2010. 15 mm deep holes were drilled in toughened steel with 6 mm drills. With rotation speed 1,326 rpm and 0.15 mm feed per rotation, the Tormek sharpened drills lasted on average 327 holes while the new drills with an s-shaped point lasted 72 holes.

The drill bit gets a four-facet point that doesn't walk. Bores a round and straight hole with close tolerances.

Sharpens all point angles

It can be set at any angle between 90° and 150°.

Sharpens drill bits from 3–22 mm

One and the same drill holder copes with all sizes between 3 mm (⅛") and 22 mm (⅞"). No change of chuck required.

Always equal cutting edges

The two cutting edges are sharpened symmetrically and work in perfect unison which prolongs the life of the drill.

Always the right clearance angle

The optimal clearance angle can be set according to each drilling requirement to 7°, 9°, 11° or 14°.

Drill Bit Sharpening With the DBS-22 Drill Bit Sharpening Attachment

Pontus and Sébastien from Tormek show you how to sharpen drill bits using the DBS-22 Drill Bit Sharpening Attachment. There's probably quite a few of us that has a bunch of dull drill bits laying around in the workshop. You'll be amazed at the incredible difference of a razor sharp, four-facet point drill compared to a conventional one. We show you how to create a four-facet point for ideal cutting performance.

The Four-facet Point

The four-facet point achieved with the DBS-22 Drill Bit Sharpening Attachment is very beneficial compared to a conventional drill bit point. It considerably decreases the force required on the core of the drill, i.e the chisel edge, which reduces the heat development and permits an increased force to the cutting edges. This gives the drill a dramatic improvement in cutting performance.

Both cutting edges are sharpened to an exact equal length and symmetrically. The four-facet geometry and the high precision sharpening makes the drill work efficiently and the life of the drill bit is considerably prolonged. The point geometry and precision sharpening is also crucial to achieve an exact and circular hole.

Choose the right point angle

Drill bits usually have a point angle of 118° or 130°. Hardened steel

and stainless steel require larger point angles. Also aluminium is best

drilled with a larger point angle. When drilling plexiglass, the risk of

cracks when the drill goes through the material is reduced with a

larger point angle. Centering drills usually have a 90° point angle.

Choose the right clearance angle

The choice of clearance angle is crucial to the cutting performance

and duration of the drill. The optimal clearance angle depends both

on the drill diameter and the material to be drilled. A harder material

requires a drill with a smaller clearance angle while a softer material

can have a larger angle. Standard drills have a clearance angle of

11° and a 118° point angle which work well for most drilling work.

How do you know if the steel has become overheated when using a dry grinder?

Overheating of the steel is often not noticeable, but the consequences are that the drill will dull rapidly and may even break. Unlike conventional drill bit sharpeners, Tormek sharpens with water cooling which is gentle on the steel.

Start with sharp tools

If you are a woodturner and have not yet discovered Tormek, there is a big chance you will be surprised to see how big a difference a really well sharpened edge can do to your final result at the lathe. As you know, the sense of control and flow at the lathe starts with sharp tools.

- Sharper woodturning tools gives better results, faster.

- Smart jigs and accessories makes sharpening incredibly fast and easy, even for tools with a complex geometry and unusual profiles.

- Water-cooled sharpening at low rpm never damage your edge.

- Shaping and sharpening on a bench grinder is possible with the extensive Tormek jig system, but heat development risks damaging your tools if you're not careful.

- Sharpening vs shaping: When sharpening a tool you just touch up the edge of an existing shape to renew the sharpness.

- Sharpening vs shaping: When shaping a tool, you remove steel to get your desired shape and edge angle. You can do both shaping and sharpening on your Tormek.

- Simple honing on the inside of arched edges, such as the edge of a bowl gouge

- Unbeatable result, appreciated by professionals worldwide.

Sharpening woodturning tools on your Tormek - instruction video with Glenn Lucas

Glenn Lucas is one of the greatest woodturners in the world. He has been using the Tormek water-cooled sharpening system for many years. He even teaches sharpening during his courses External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

Sharpening Class - Woodturning tools

In this episode, Wolfgang and Sébastien from Tormek demonstrate how you sharpen tools for the woodturner; gouges, skews, parting tools, scrapers, cutters and more. We show you the methods for sharpening all these turning tools and how you achieve repeatable edges every time. This class is based on the jigs and accessories included in the TNT-808 Woodturner's Kit, which includes everything you need to sharpen and shape your woodturning tools.

Sharpen Less – Turn More!

The Tormek way of sharpening differs from other grinding methods like high-speed bench grinders and belt sanders. Tormek makes a clear distinction between shaping and sharpening. Once the tool is shaped to the right shape, you remove only a minimal amount of steel when sharpening – you just touch up the edge. An important benefit of the minimal steel removal is that the sharpening is fast, in addition, your precious tools will last much longer.

With the patented TTS-100 Turning Tool Setter every aspect of the set-up is simple and you can be sure to get the exact same shape of your tool every time you sharpen, regardless if the you have a grindstone that will get a smaller diameter over the years.

The high level

Knife Sharpening

Learn how to sharpen knives like a pro - quick and easy!

- Knowledge

- How to Sharpen Your Tools

- Knife Sharpening

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

How to sharpen your tools

For professional crafts, hobby or culinary use

Sharpen your knives and other tools to a durable and razor-sharp result. Tormek's sharpening machines provides you with the possibility to sharpen different knives and tools for professional and hobby use.

Woodcarving Tools

Sharp tools cuts cleaner

Hunting & Outdoor Tools

Sharpen knives and axes for hunting and outdoor

Knife Sharpening for the Commercial Kitchen

Achieve a more efficient kitchen with sharp knives

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

Give New Life to Your Drill Bits

With the patented DBS-22 Drill Bit Sharpening Attachment you can sharpen your drill bits with the highest precision. The optimal point and clearance angles can be set according to each drilling requirement, which depends upon the drill size and material. You can completely restore worn drills as well as broken drills to a perfect shape.

A Better Cutting Geometry

When you sharpen your drill bits with the DBS-22 Drill Bit Sharpening Attachment, you create a four-facet point which gives the ideal cutting performance since the chisel edge gets a point instead of being almost flat as on many drills. A four-facet point will not walk and the thrust force required is considerably reduced compared to a conventional cone point drill.

A precision sharpened four-facet point generates less heat and the life of the drill is therefore also prolonged. Independent tests show that a Tormek sharpened drill lasts up to 4 times longer than a brand new conventional drill bit¹.

¹Uddeholm Tooling AB, 2010. 15 mm deep holes were drilled in toughened steel with 6 mm drills. With rotation speed 1,326 rpm and 0.15 mm feed per rotation, the Tormek sharpened drills lasted on average 327 holes while the new drills with an s-shaped point lasted 72 holes.

The drill bit gets a four-facet point that doesn't walk. Bores a round and straight hole with close tolerances.

Sharpens all point angles

It can be set at any angle between 90° and 150°.

Sharpens drill bits from 3–22 mm

One and the same drill holder copes with all sizes between 3 mm (⅛") and 22 mm (⅞"). No change of chuck required.

Always equal cutting edges

The two cutting edges are sharpened symmetrically and work in perfect unison which prolongs the life of the drill.

Always the right clearance angle

The optimal clearance angle can be set according to each drilling requirement to 7°, 9°, 11° or 14°.

Drill Bit Sharpening With the DBS-22 Drill Bit Sharpening Attachment

Pontus and Sébastien from Tormek show you how to sharpen drill bits using the DBS-22 Drill Bit Sharpening Attachment. There's probably quite a few of us that has a bunch of dull drill bits laying around in the workshop. You'll be amazed at the incredible difference of a razor sharp, four-facet point drill compared to a conventional one. We show you how to create a four-facet point for ideal cutting performance.

The Four-facet Point

The four-facet point achieved with the DBS-22 Drill Bit Sharpening Attachment is very beneficial compared to a conventional drill bit point. It considerably decreases the force required on the core of the drill, i.e the chisel edge, which reduces the heat development and permits an increased force to the cutting edges. This gives the drill a dramatic improvement in cutting performance.

Both cutting edges are sharpened to an exact equal length and symmetrically. The four-facet geometry and the high precision sharpening makes the drill work efficiently and the life of the drill bit is considerably prolonged. The point geometry and precision sharpening is also crucial to achieve an exact and circular hole.

Choose the right point angle

Drill bits usually have a point angle of 118° or 130°. Hardened steel

and stainless steel require larger point angles. Also aluminium is best

drilled with a larger point angle. When drilling plexiglass, the risk of

cracks when the drill goes through the material is reduced with a

larger point angle. Centering drills usually have a 90° point angle.

Choose the right clearance angle

The choice of clearance angle is crucial to the cutting performance

and duration of the drill. The optimal clearance angle depends both

on the drill diameter and the material to be drilled. A harder material

requires a drill with a smaller clearance angle while a softer material

can have a larger angle. Standard drills have a clearance angle of

11° and a 118° point angle which work well for most drilling work.

How do you know if the steel has become overheated when using a dry grinder?

Overheating of the steel is often not noticeable, but the consequences are that the drill will dull rapidly and may even break. Unlike conventional drill bit sharpeners, Tormek sharpens with water cooling which is gentle on the steel.

Start with sharp tools

If you are a woodturner and have not yet discovered Tormek, there is a big chance you will be surprised to see how big a difference a really well sharpened edge can do to your final result at the lathe. As you know, the sense of control and flow at the lathe starts with sharp tools.

- Sharper woodturning tools gives better results, faster.

- Smart jigs and accessories makes sharpening incredibly fast and easy, even for tools with a complex geometry and unusual profiles.

- Water-cooled sharpening at low rpm never damage your edge.

- Shaping and sharpening on a bench grinder is possible with the extensive Tormek jig system, but heat development risks damaging your tools if you're not careful.

- Sharpening vs shaping: When sharpening a tool you just touch up the edge of an existing shape to renew the sharpness.

- Sharpening vs shaping: When shaping a tool, you remove steel to get your desired shape and edge angle. You can do both shaping and sharpening on your Tormek.

- Simple honing on the inside of arched edges, such as the edge of a bowl gouge

- Unbeatable result, appreciated by professionals worldwide.

Sharpening woodturning tools on your Tormek - instruction video with Glenn Lucas

Glenn Lucas is one of the greatest woodturners in the world. He has been using the Tormek water-cooled sharpening system for many years. He even teaches sharpening during his courses External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

Sharpening Class - Woodturning tools

In this episode, Wolfgang and Sébastien from Tormek demonstrate how you sharpen tools for the woodturner; gouges, skews, parting tools, scrapers, cutters and more. We show you the methods for sharpening all these turning tools and how you achieve repeatable edges every time. This class is based on the jigs and accessories included in the TNT-808 Woodturner's Kit, which includes everything you need to sharpen and shape your woodturning tools.

Sharpen Less – Turn More!

The Tormek way of sharpening differs from other grinding methods like high-speed bench grinders and belt sanders. Tormek makes a clear distinction between shaping and sharpening. Once the tool is shaped to the right shape, you remove only a minimal amount of steel when sharpening – you just touch up the edge. An important benefit of the minimal steel removal is that the sharpening is fast, in addition, your precious tools will last much longer.

With the patented TTS-100 Turning Tool Setter every aspect of the set-up is simple and you can be sure to get the exact same shape of your tool every time you sharpen, regardless if the you have a grindstone that will get a smaller diameter over the years.

The high level

Knife Sharpening

Learn how to sharpen knives like a pro - quick and easy!

- Knowledge

- How to Sharpen Your Tools

- Knife Sharpening

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

How to sharpen your tools

For professional crafts, hobby or culinary use

Sharpen your knives and other tools to a durable and razor-sharp result. Tormek's sharpening machines provides you with the possibility to sharpen different knives and tools for professional and hobby use.

Woodcarving Tools

Sharp tools cuts cleaner

Hunting & Outdoor Tools

Sharpen knives and axes for hunting and outdoor

Knife Sharpening for the Commercial Kitchen

Achieve a more efficient kitchen with sharp knives

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

Give New Life to Your Drill Bits

With the patented DBS-22 Drill Bit Sharpening Attachment you can sharpen your drill bits with the highest precision. The optimal point and clearance angles can be set according to each drilling requirement, which depends upon the drill size and material. You can completely restore worn drills as well as broken drills to a perfect shape.

A Better Cutting Geometry

When you sharpen your drill bits with the DBS-22 Drill Bit Sharpening Attachment, you create a four-facet point which gives the ideal cutting performance since the chisel edge gets a point instead of being almost flat as on many drills. A four-facet point will not walk and the thrust force required is considerably reduced compared to a conventional cone point drill.

A precision sharpened four-facet point generates less heat and the life of the drill is therefore also prolonged. Independent tests show that a Tormek sharpened drill lasts up to 4 times longer than a brand new conventional drill bit¹.

¹Uddeholm Tooling AB, 2010. 15 mm deep holes were drilled in toughened steel with 6 mm drills. With rotation speed 1,326 rpm and 0.15 mm feed per rotation, the Tormek sharpened drills lasted on average 327 holes while the new drills with an s-shaped point lasted 72 holes.

The drill bit gets a four-facet point that doesn't walk. Bores a round and straight hole with close tolerances.

Sharpens all point angles

It can be set at any angle between 90° and 150°.

Sharpens drill bits from 3–22 mm

One and the same drill holder copes with all sizes between 3 mm (⅛") and 22 mm (⅞"). No change of chuck required.

Always equal cutting edges

The two cutting edges are sharpened symmetrically and work in perfect unison which prolongs the life of the drill.

Always the right clearance angle

The optimal clearance angle can be set according to each drilling requirement to 7°, 9°, 11° or 14°.

Drill Bit Sharpening With the DBS-22 Drill Bit Sharpening Attachment

Pontus and Sébastien from Tormek show you how to sharpen drill bits using the DBS-22 Drill Bit Sharpening Attachment. There's probably quite a few of us that has a bunch of dull drill bits laying around in the workshop. You'll be amazed at the incredible difference of a razor sharp, four-facet point drill compared to a conventional one. We show you how to create a four-facet point for ideal cutting performance.

The Four-facet Point

The four-facet point achieved with the DBS-22 Drill Bit Sharpening Attachment is very beneficial compared to a conventional drill bit point. It considerably decreases the force required on the core of the drill, i.e the chisel edge, which reduces the heat development and permits an increased force to the cutting edges. This gives the drill a dramatic improvement in cutting performance.

Both cutting edges are sharpened to an exact equal length and symmetrically. The four-facet geometry and the high precision sharpening makes the drill work efficiently and the life of the drill bit is considerably prolonged. The point geometry and precision sharpening is also crucial to achieve an exact and circular hole.

Choose the right point angle

Drill bits usually have a point angle of 118° or 130°. Hardened steel

and stainless steel require larger point angles. Also aluminium is best

drilled with a larger point angle. When drilling plexiglass, the risk of

cracks when the drill goes through the material is reduced with a

larger point angle. Centering drills usually have a 90° point angle.

Choose the right clearance angle

The choice of clearance angle is crucial to the cutting performance

and duration of the drill. The optimal clearance angle depends both

on the drill diameter and the material to be drilled. A harder material

requires a drill with a smaller clearance angle while a softer material

can have a larger angle. Standard drills have a clearance angle of

11° and a 118° point angle which work well for most drilling work.

How do you know if the steel has become overheated when using a dry grinder?

Overheating of the steel is often not noticeable, but the consequences are that the drill will dull rapidly and may even break. Unlike conventional drill bit sharpeners, Tormek sharpens with water cooling which is gentle on the steel.

Start with sharp tools

If you are a woodturner and have not yet discovered Tormek, there is a big chance you will be surprised to see how big a difference a really well sharpened edge can do to your final result at the lathe. As you know, the sense of control and flow at the lathe starts with sharp tools.

- Sharper woodturning tools gives better results, faster.

- Smart jigs and accessories makes sharpening incredibly fast and easy, even for tools with a complex geometry and unusual profiles.

- Water-cooled sharpening at low rpm never damage your edge.

- Shaping and sharpening on a bench grinder is possible with the extensive Tormek jig system, but heat development risks damaging your tools if you're not careful.

- Sharpening vs shaping: When sharpening a tool you just touch up the edge of an existing shape to renew the sharpness.

- Sharpening vs shaping: When shaping a tool, you remove steel to get your desired shape and edge angle. You can do both shaping and sharpening on your Tormek.

- Simple honing on the inside of arched edges, such as the edge of a bowl gouge

- Unbeatable result, appreciated by professionals worldwide.

Sharpening woodturning tools on your Tormek - instruction video with Glenn Lucas

Glenn Lucas is one of the greatest woodturners in the world. He has been using the Tormek water-cooled sharpening system for many years. He even teaches sharpening during his courses External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

External link, opens in new window. at his study centre in Carlow, Ireland. In this instructional video he demonstrate how you sharpen your woodturning tools on your Tormek.

Sharpening Class - Woodturning tools

In this episode, Wolfgang and Sébastien from Tormek demonstrate how you sharpen tools for the woodturner; gouges, skews, parting tools, scrapers, cutters and more. We show you the methods for sharpening all these turning tools and how you achieve repeatable edges every time. This class is based on the jigs and accessories included in the TNT-808 Woodturner's Kit, which includes everything you need to sharpen and shape your woodturning tools.

Sharpen Less – Turn More!

The Tormek way of sharpening differs from other grinding methods like high-speed bench grinders and belt sanders. Tormek makes a clear distinction between shaping and sharpening. Once the tool is shaped to the right shape, you remove only a minimal amount of steel when sharpening – you just touch up the edge. An important benefit of the minimal steel removal is that the sharpening is fast, in addition, your precious tools will last much longer.

With the patented TTS-100 Turning Tool Setter every aspect of the set-up is simple and you can be sure to get the exact same shape of your tool every time you sharpen, regardless if the you have a grindstone that will get a smaller diameter over the years.

The high level

Knife Sharpening

Learn how to sharpen knives like a pro - quick and easy!

- Knowledge

- How to Sharpen Your Tools

- Knife Sharpening

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

How to sharpen your tools

For professional crafts, hobby or culinary use

Sharpen your knives and other tools to a durable and razor-sharp result. Tormek's sharpening machines provides you with the possibility to sharpen different knives and tools for professional and hobby use.

Woodcarving Tools

Sharp tools cuts cleaner

Hunting & Outdoor Tools

Sharpen knives and axes for hunting and outdoor

Knife Sharpening for the Commercial Kitchen

Achieve a more efficient kitchen with sharp knives

Quick, easy, and precise sharpening

The Tormek knife jigs and angle guides enable you to restore your knife blade to its original and optimal edge angle - and sharper than when you got them! You'll get symmetrical, even, and clean bevels that meet up in a razor sharp apex. When you no longer get the sharpness you need by realigning the apex with a sharpening steel or honing rod, you can resharpen and reestablish the bevels to the intended angle for your knife with your Tormek machine.

A durable edge

With the Tormek knife jigs and angle guides, you are in full control and get a consistent bevel and angle along the entire knife blade. If you resharpen the knife to its original edge angle, you avoid removing an unnecessary amount of steel, making the sharpening very efficient. It also minimize wear on your knives and you will love the feeling of always working with a really sharp knife with the ideal edge angle.

You don't always have to resharpen your knife. Often it's enough just touching up the edge with your Tormek honing wheel, a sharpening steel, a honing rod, or manual whetstones. Just keep in mind that the edge angle will unintentionally increase a bit each time. After a few touch ups you need to restore and resharpen both the entire bevels to the intended edge angle.

From sharp to dull, to sharp again

- A sharp edge.

- The edge is worn and blunt.

- After honing on your Tormek honing wheel, a whetstone, or with a sharpening steel, the edge is sharp again, but with an increased edge angle.

4. After another period of use the edge is blunt again.

5. Another honing sharpens the edge to a still larger angle.

6. The edge is now re-ground with Tormek to its original shape and edge angle.

Knife sharpening angles - Manufacturer's recommendations

The recommended edge angle of your knife is often written on the knife's packaging. If you don’t find it there you can often find it on the manufacturer’s website. We have created a list where you find the angle recommendations from some “well-known” knife manufacturers.

Which Tormek for knife sharpening?

Are you curious as to which Tormek machine is best for your knife sharpening needs? Check out this buyer's guide where we let you know which Tormek is right for you!

Getting started with kitchen knives

Do you want to have razor sharp kitchen knives quick and easy, and nothing else? Check out this getting started-video for the Tormek T-1 Kitchen Knife Sharpener - the first real knife sharpener for the home chef!

Gentle on the steel

Due to the ability to set an exact sharpening angle, and the low rpm, Tormek machines remove a minimum amount of steel. This also ensures you never overheat and detemper the steel in your precious knives. On the Tormek water-cooled systems, the edge is also continuously cooled with water during sharpening. This is required when sharpening with grindstones and acts as a lubricant.

Superior sharpness

When resharpening a knife, something called a "burr" is created. It is residues of the metal you have ground away that collects at the new apex of your knife on the opposite side you last sharpened. To get a truly sharp knife with a durable edge you need to remove the burr, or "deburr" your knife, and polish your new bevels. Both deburring and polishing is easily done on the honing wheel, which provide the real razor sharpness if the previous step of sharpening has been done correctly. You'll get a very nice edge that will last longer.

Edge angles for different types of knives

The ideal edge angle is depending on the type of knife and the area of use. A knife for cutting meat should have a larger edge angle than a knife for cutting vegetables. A small edge angle of 24° will cut easily but it will also be more sensitive to wear and damage. A larger edge angle of 40° will give a stronger and more durable edge. Down below we suggest some edge angles for different types of knives.

Woodcarving Knives

Slicing, Filleting and Paring Knives

Knives for Butchers, Chefs and Kitchens

Hunting and Sporting Knives

Sharpening long knives and cleavers

Sometimes your regular Universal Support just doesn't cut it. It might bee too short lengthwise or hightwise. With the US-430 Extended Universal Support you can sharpen both longer and taller blades, such as long knives, cleavers and machetes. Like our other Universal Supports, it has the Micro Adjust with a scale for precise setting of the angle.

Give New Life to Your Drill Bits