E-Catalog > SMW AUTOBLOK > OML STATIONARY WORKHOLDING

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- SMW AUTOBLOK

- สินค้า, ผลิตภัณฑ์

Product Detail :

OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING OML STATIONARY WORKHOLDING

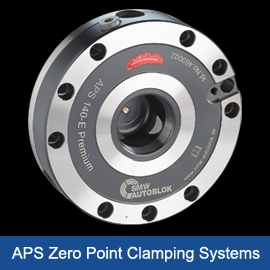

Large entry radii of the clamping pins ensure easy and safe loading.

Large entry radii of the clamping pins ensure easy and safe loading.