Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- AIR CHUCK

- สินค้า, ผลิตภัณฑ์

Product Detail :

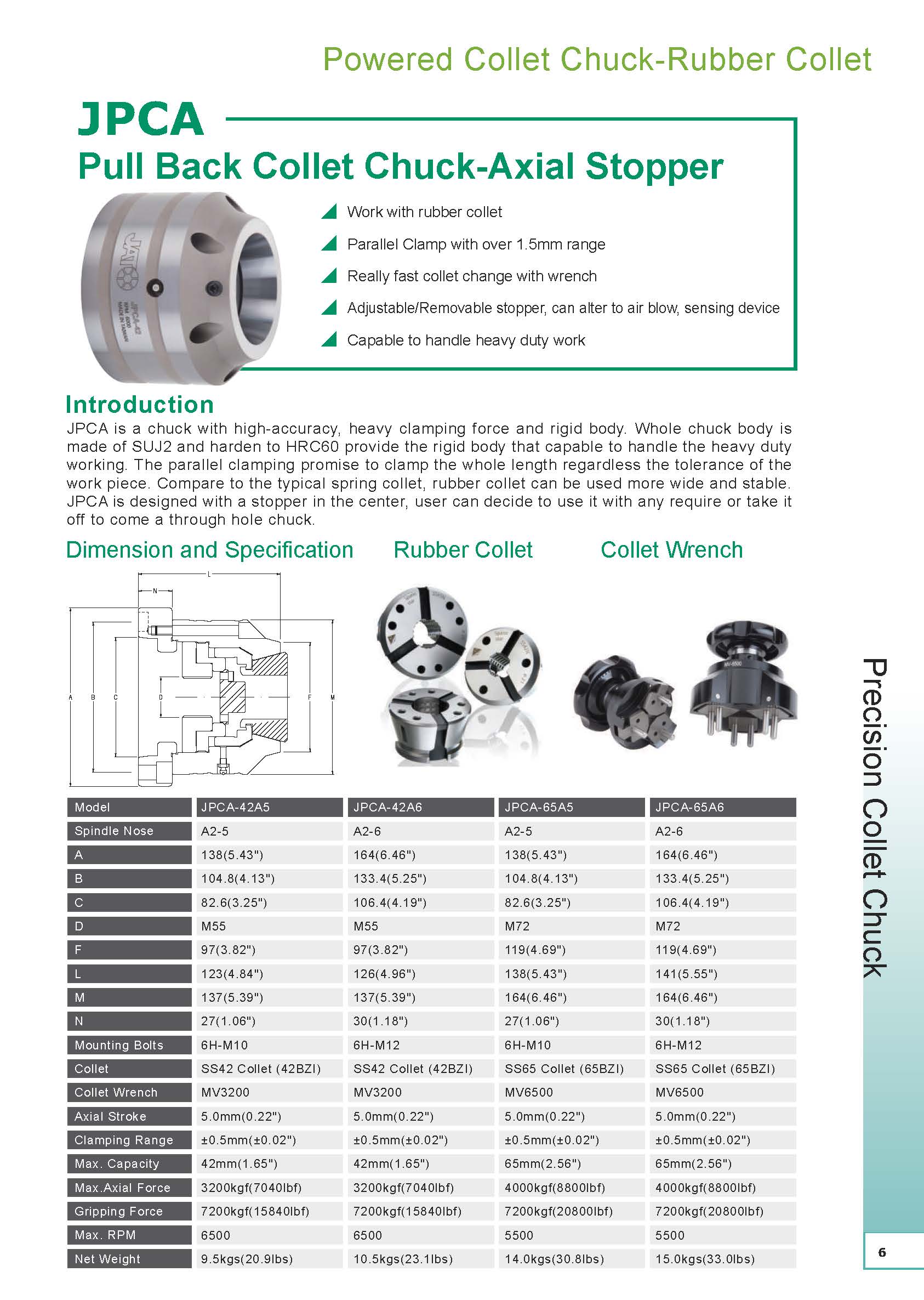

Rotary Power Chuck-C Type Jaw Pad

JA5-25/JH5-25/JA7-40/JH7-40/JA7-70/JH7-70/JH9-90/JH9-120

|

JA/JH Rotary Power Chuck

Intoduction ▲ Built in rotary cylinder ▲ No draw tube,no rotary cylinder required ▲ Extra large piston,provide high clamping force ▲ Center through hole,able to arrange auto feeding ▲ Best budget solution for manual lathe into automation ▲ No fluid direct to the chuck body

Dimensions and Specifications

Modle Sheet with Jaw Pad

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

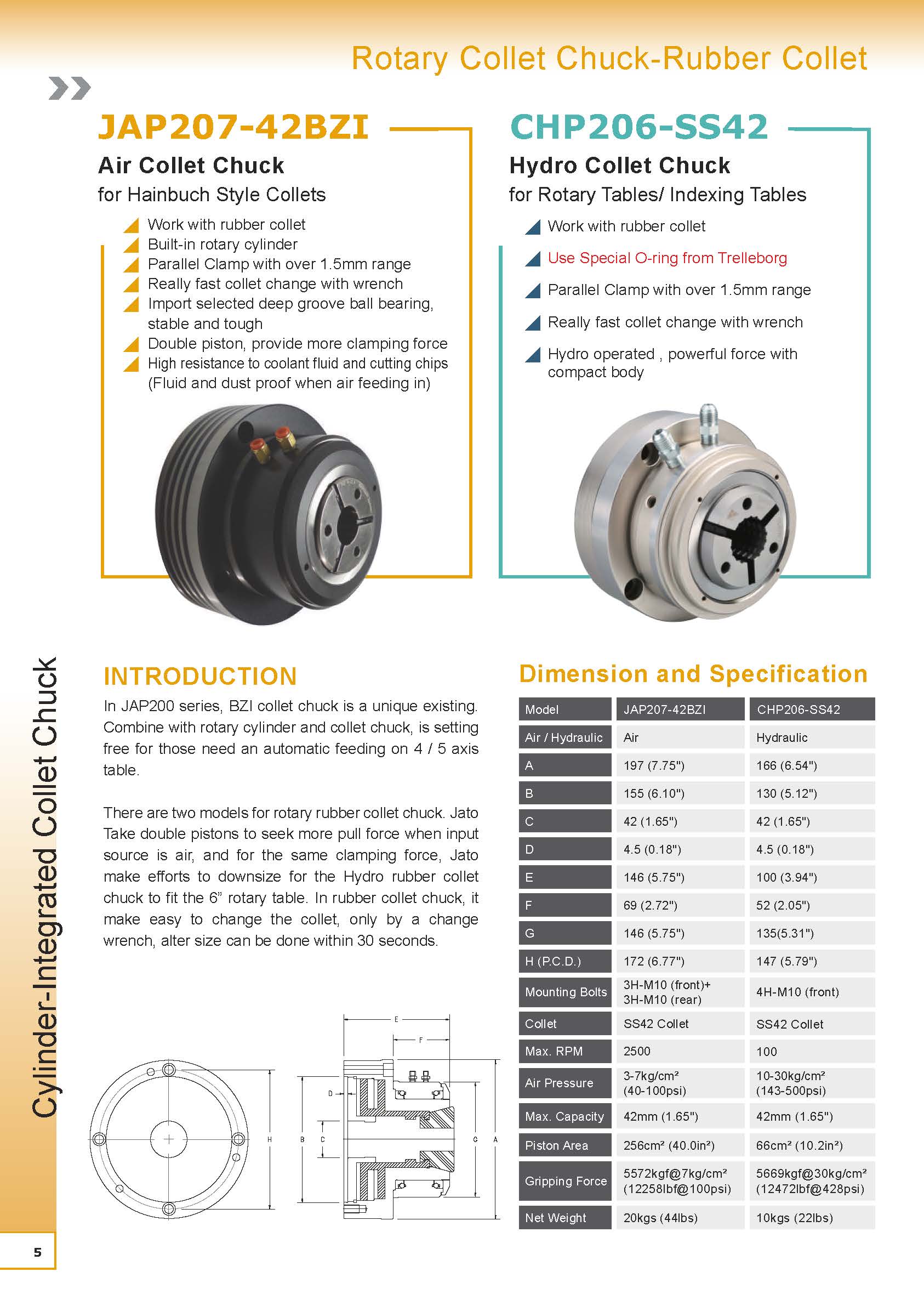

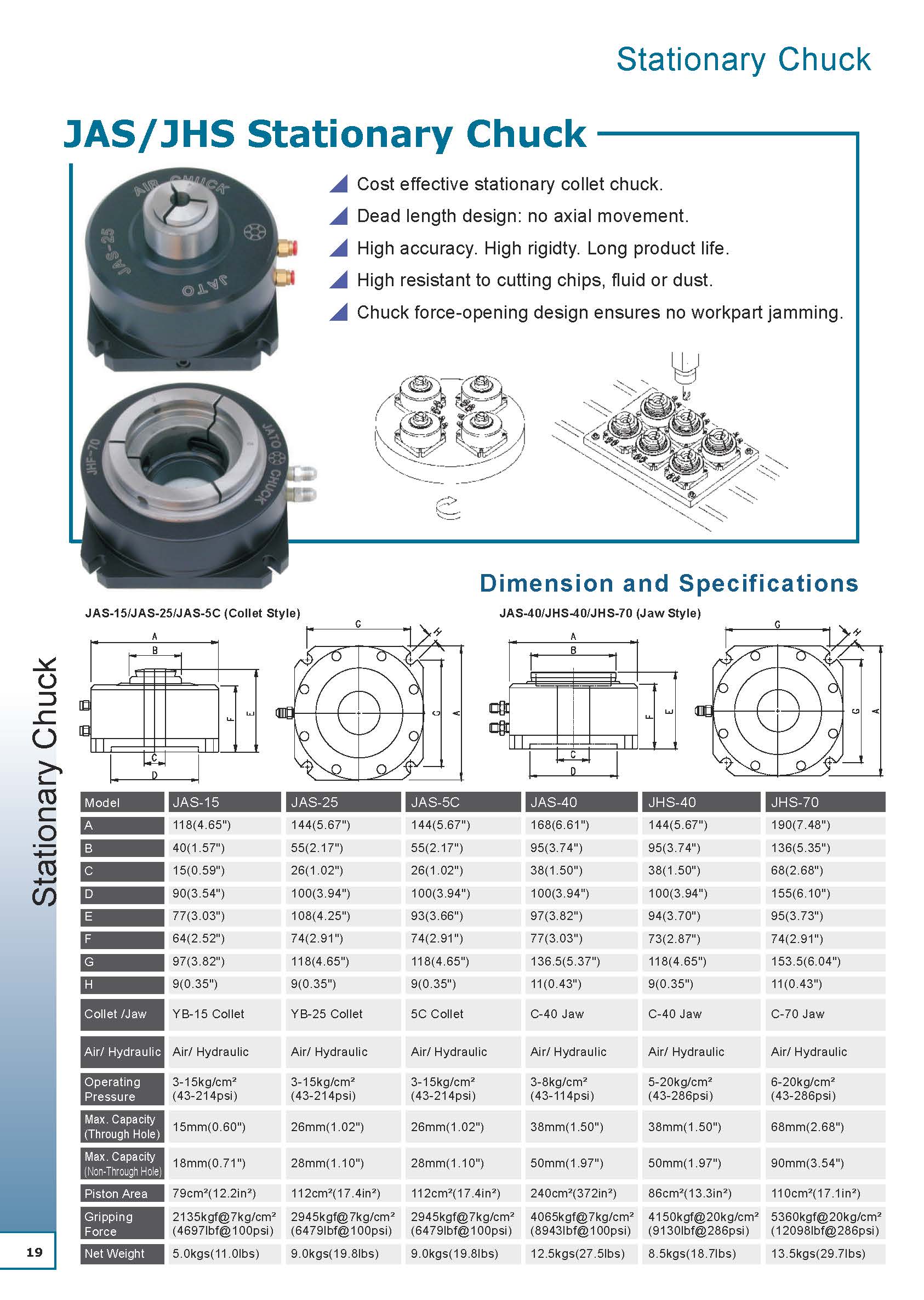

JAS/JHS Stationary Collet Chuck

JAS-15/JAS-25/JAS-5C/JAS-40/JHS-40/JHS-70

JAS/JHS Stationary Chuck

|

Product Features ◢ Cost effective stationary collet chuck. ◢ Dead length design:no axial movement. ◢ High accuracy.High rigidty.Long product life. ◢ High resistant to cutting chips,fluid or dust. |

||

|

▲CNC tapping centers |

▲Rotary SPMs (Special Purpode Machines) |

|

|

◢ Chuck force-opening design ensures no workpart jamming |

||

Dimension and Specifications

|

( unit : mm ) |

|||||||||||||||

|

Collet Style Stationary Chuck |

|||||||||||||||

|

|

A |

B |

C |

D |

E |

F |

G |

Piston Area |

|||||||

|

JAS-15 |

118 ( 4.65" ) |

40 ( 1.57" ) |

15 ( 0.59" ) |

77 ( 3.03" ) |

64 ( 2.52" ) |

97 ( 3.82" ) |

9 ( 0.35" ) |

79cm2 (12.2in2 ) |

|||||||

|

JAS-25 |

144 ( 5.67" ) |

55 ( 2.17" ) |

26 ( 1.02" ) |

105 ( 4.13" ) |

74 ( 2.91" ) |

118 ( 4.65" ) |

112cm2 (17.4in2 ) |

||||||||

|

JAS-5C |

90 ( 3.54" ) |

||||||||||||||

|

|

Collet |

Air/Hydraulic |

Operating Pressure |

Max. Capacity (Through/ None) |

Gripping Force |

Net Weight |

|

JAS-15 |

YB-15 |

Air/Hydraulic |

3-15kg/cm2 ( 43-214psi ) |

15mm/18mm ( 0.60"/0.71" ) |

2135 kgf@7kg/cm2 ( 4706lbs@100psi ) |

4.7 kgs ( 11.0lbs ) |

|

JAS-25 |

YB-25 |

26mm/28mm ( 1.02"/1.10" ) |

2945 kgf@7kg/cm2 ( 6493lbs@100psi ) |

8.5 kgs ( 19.8lbs ) |

||

|

JAS-5C |

5C |

8.4 kgs ( 17.6lbs ) |

|

( unit : mm ) |

||||||||||||

|

Jaw Style Stationary Chuck |

||||||||||||

|

|

A |

B |

C |

D |

E |

F |

G |

Piston Area |

||||

|

JAS-40 |

168 (6.61") |

95 (3.74") |

38 (1.50") |

97 (3.82") |

77.5 ( 3.05") |

136.5 (5.37") |

11 (0.43") |

240cm2 (37.2in2) |

|

|||

|

JHS-40 |

144 (5.67") |

94.5 ( 3.72") |

73 (2.87") |

118 (4.65") |

9 (0.35") |

86cm2 (13.3in2) |

|

|||||

|

JHS-70 |

190 (7.48") |

136 (5.35") |

68 (2.68") |

74 (2.91") |

153.5 (6.04") |

11 (0.43") |

110cm2 (17.1in2) |

|

||||

|

|

Jaw |

Air/Hydraulic |

Operating Pressure |

Max. Capacity (Through/ None) |

Gripping Force |

Net Weight |

|

JAS-40 |

C-40 |

Air/Hydraulic |

3-8 kg/cm2 ( 43-114psi ) |

38mm/50mm ( 1.50"/1.97" ) |

4065 kgf@7kg/cm2 ( 8962lbs@100psi ) |

12.1 kgs ( 26.7 lbs ) |

|

JHS-40 |

5-20 kg/cm2 ( 71-285psi ) |

4150 kgf@20kg/cm2 ( 9149lbs@285psi ) |

8.2 kgs ( 18.1 lbs ) |

|||

|

JHS-70 |

C-70 |

6-20 kg/cm2 ( 85-285psi ) |

68mm/90mm ( 2.68"/3.54" ) |

5360 kgf@20kg/cm2 ( 11817lbs@285psi ) |

12.7 kgs ( 28.0 lbs ) |

|

( unit : mm ) |

|||||||

|

Draw-back collet |

Max. Capacity |

||||||

|

Model |

d |

D |

L |

M ( Thread ) |

Round |

Square |

Hexagon |

|

YB-15 |

19 ( 0.75" ) |

26 ( 1.02" ) |

76 ( 2.99" ) |

M18xP1.2 |

16.2 ( 0.64" ) |

10.6 ( 0.42" ) |

13 ( 0.51" ) |

|

YB-25 |

32 ( 1.26" ) |

39.5 ( 1.56" ) |

102 ( 1.02" ) |

M31.5x20T |

27 ( 1.06" ) |

19 ( 0.75" ) |

23 |

|

5C |

31.75 ( 1.25" ) |

37.5 ( 1.48" ) |

87 ( 3.43" ) |

M31.5x20T |

26 ( 1.02" ) |

19 ( 0.75" ) |

23 |

|

16C |

48 ( 1.89" ) |

58 ( 0.28" ) |

114 ( 4.49" ) |

M47.5xP1.75 |

40 ( 1.57" ) |

28.2 ( 1.11" ) |

34.6 ( 1.36" ) |

|

( unit : mm ) |

|||||||||

|

Model |

A |

B |

C |

D |

Bolts |

||||

|

C-25 |

47.5mm ( 1.87" ) |

45mm ( 1.77" ) |

3.5mm ( 0.13" ) |

7mm ( 0.28" ) |

M5x10 |

||||

|

C-40 |

67.5mm ( 2.66" ) |

65mm ( 2.56" ) |

6.0mm ( 0.24" ) |

9mm ( 0.35" ) |

M6x12 |

||||

|

C-70 |

107.5mm ( 4.23" ) |

105mm ( 4.13" ) |

6.0mm ( 0.24" ) |

9mm ( 0.35" ) |

M6x12 |

||||

|

C-120 |

143.5mm ( 5.65" ) |

140mm ( 5.51" ) |

6.0mm ( 0.24" ) |

9mm ( 0.35" ) |

M6x14 |

||||

|

|

|||||||||

|

Varies Type of Jaw Pad |

|||||||||

|

Through Hole |

Step |

Serrated |

Square,Hexagon |

Extra Iength |

|||||

JAS Stationary Collet Chuck-Pull back

JAS-5C-PL / JAS-16C-PL

|

|

JAS-5C-PL/JAS-16C-PL Stationary Collet Chuck-Pull Back

Dimension and Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

( unit : mm ) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Draw-back collet |

Max. Capacity |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Model |

d |

Slope |

L |

M(Thread) |

D |

Round |

Square |

Hexagon |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5C |

31.75 ( 1.25" ) |

10° |

87 ( 3.43" ) |

M31.5x20T |

37.5 ( 1.48" ) |

26 ( 1.02" ) |

19 ( 0.75" ) |

23 ( 0.91" ) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16C |

48 ( 1.89" ) |

10° |

114.0 ( 4.49" ) |

M47.5xP1.75 |

58 ( 2.28" ) |

40 ( 1.57" ) |

28.2 ( 1.11" ) |

34.6 ( 1.36" ) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

JAP100 Pneumatic Diaphragm Chuck

JAP104/JAP105/JAP106

JAP100 Air Diaphragm Chuck

|

Product Features ◢ Center through hole design,allow to set air blow or stopper in axis way ◢ Highly-sealed chuck body,helps protect cutting chips,dust or coolant fluid from entering ◢ Air cylinder intergrated,no rotary cylinder and draw bar required ◢ Gentle and Precise clamping,best for fragile and thin-wall work piece |

||

|

◢ Repeatability within 5 um ◢ Front-mount design make installation easy ◢ O.D / I.D clamping applies by only switch the jaw pad ◢ Please use 5um filter in F.R.L units |

▲5μm Filter Applies in all series of JAP100/JAP200, a set go along with packing |

|

Applications

◢ Spindle Grinding of DC Micro Motors

◢ Precise Bush

◢ Lens of Electronic Equipment

◢ Lens Frame of Smartphone

◢ Precision Sleeve

◢ Ceramics Grinding

◢ Cardiovascular stent

◢ Laser Carving, Laser Cutting, Laser W ielding

◢ Case of Stylus

JAP100 Dimension and Specification

|

|

|||||||||

|

( unit : mm ) |

|

||||||||

|

|

A |

B |

C |

D |

E |

F(P.C.D.) |

G |

H |

|

|

JAP-104 |

100 ( 3.94" ) |

65 ( 2.56" ) |

4.5 ( 0.18" ) |

M21xP1.5 |

70 ( 2.76" ) |

82 ( 3.22" ) |

97 ( 3.82" ) |

73 ( 2.87" ) |

|

|

JAP-105 |

137 ( 5.39" ) |

70 ( 2.76" ) |

4 ( 0.16" ) |

M35xP1.5 |

100 ( 3.94" ) |

115 ( 4.53" ) |

135 ( 5.31" ) |

90 ( 3.54" ) |

|

|

JAP-106 |

164.5 ( 6.48" ) |

100 ( 3.94" ) |

6 ( 0.24" ) |

M60xP1.5 |

130 ( 5.12" ) |

147 ( 5.79" ) |

167 ( 6.57" ) |

107 ( 4.21" ) |

|

|

|

Mounting Blots |

Max. RPM |

Air Pressure |

Jaw Opening |

Through Hole |

Net Weight |

|

JAP-104 |

4H-M6 ( front ) |

4000 |

0.5-7kg/cm2 ( 7-100psi ) |

0.20mm ( 0.008" ) |

10mm ( 0.39" ) |

2.6kgs ( 6.2lbs ) |

|

JAP-105 |

3H-M8 ( front )+ |

3400 |

14mm ( 0.57" ) |

6.0kgs ( 13.2lbs ) |

||

|

JAP-106 |

3H-M10 ( front )+ 3H-M10 ( rear ) |

2400 |

42mm ( 1.65" ) |

10.5kgs ( 20.9lbs ) |

|

( unit : mm ) |

||||||||

|

|

A |

B |

C |

D |

E |

F |

G |

Jaw Split |

|

JD-60 |

65 ( 2.56" ) |

45 ( 1.77" ) |

32 ( 1.26" ) |

5 ( 0.20" ) |

4 ( 0.16" ) |

12 ( 0.47" ) |

Ø52-M5 |

6 |

|

JD-70 |

75 ( 2.95" ) |

50 ( 1.97" ) |

37 ( 1.46" ) |

5.5 ( 0.22" ) |

4.5 ( 0.18" ) |

13.5 ( 0.53" ) |

Ø60-M5 |

6 |

|

JD-100 |

105 ( 4.13" ) |

80.2 ( 3.16" ) |

65 ( 2.56" ) |

6 ( 0.24" ) |

5.5 ( 0.22" ) |

14 ( 0.55" ) |

Ø90-M5 |

8 |

Customize Make Jaw Pad for JAP100 Series

3-Jaws Diaphragm Chuck

JP-05/06/08/10

|

JP Series High Speed Diaphragm Chuck ◢ 0.005mm repeatability ◢ Anti centrifugal force design. Clamping force remains high in high R.P.M. ◢ Integrated dynamic-balancing-weights for fine balance adjustment ◢ No sliding parts to wear out.Clamping force/stroke is proportional to actuating force. ◢ Ideal for fragile parts, or thin-wall parts clamping. |

JPL Series Diaphragm Chuck for Grinders ◢ 0.005mm repeatability ◢ Compact size. Light weighted. ◢ Special for precision grinders ◢ No sliding parts to wear out. ◢ Clamping force/stroke is proportional to actuating force. ◢ Ideal for fragile parts, or thin-wall parts clamping. |

||||||||||

|

|

|||||||||||

|

( unit : mm ) |

|||||||||||

|

JP Series |

|||||||||||

|

|

A |

B |

C |

E |

D |

||||||

|

JP-05 |

147 ( 5.79" ) |

68 ( 2.68" ) |

110 ( 4.33" ) |

M40xP1.5 |

4 ( 0.16" ) |

||||||

|

JP-06 |

182 ( 7.17" ) |

87.5 ( 3.44" ) |

140 ( 5.51" ) |

M55xP2.0 |

5 ( 0.2" ) |

||||||

|

JP-08 |

232 ( 9.13" ) |

98 ( 3.86" ) |

170 ( 6.69" ) |

M60xP2.0 |

|||||||

|

JP-10 |

267 ( 10.51" ) |

105 ( 4.13" ) |

220 ( 8.66" ) |

M85xP2.0 |

|||||||

|

|

F |

G(P.C.D.) |

H |

I |

M |

N |

|||||

|

JP-05 |

33 ( 1.30" ) |

82.6 ( 3.25" ) |

14 ( 0.55" ) |

13 ( 0.51" ) |

M10x3 |

136 ( 5.35" ) |

|||||

|

JP-06 |

44 ( 1.73" ) |

104.8 ( 4.13" ) |

20 ( 0.79" ) |

15.5 ( 0.61" ) |

M10x6 |

170.5 ( 6.71" ) |

|||||

|

JP-08 |

50 ( 1.97" ) |

133.4 ( 5.25" ) |

25 ( 0.98" ) |

17 ( 0.67" ) |

M12x6 |

217 ( 8.54" ) |

|||||

|

JP-10 |

75 ( 2.95" ) |

171.4 ( 6.75" ) |

30 ( 1.18" ) |

M16x6 |

256 ( 10.08" ) |

||||||

|

|

|||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

( unit:mm ) |

|

|||||||||||||||||||||||||||||||||||

|

JPL Series |

|

|||||||||||||||||||||||||||||||||||

|

|

A |

B |

C |

D |

E |

F |

|

|||||||||||||||||||||||||||||

|

JP-06L |

182 ( 7.17" ) |

87.5 ( 3.44" ) |

140 ( 5.51" ) |

5 ( 0.20" ) |

M55xP2.0 |

44 ( 1.73" ) |

|

|||||||||||||||||||||||||||||

|

JP-08L |

217 ( 8.54" ) |

68.5 ( 2.70" ) |

170 ( 6.69" ) |

M60xP2.0 |

50 ( 1.97" ) |

|

||||||||||||||||||||||||||||||

|

|

G(P.C.D.) |

H |

I |

M |

N |

|||||||||||||||||||||||||||||||

|

JP-06L |

104.8 ( 4.13" ) |

20 ( 0.79" ) |

15.5 ( 0.61" ) |

M10x6 |

170.5 ( 6.71" ) |

|||||||||||||||||||||||||||||||

|

JP-08L |

133.4 ( 5.25" ) |

25 ( 0.98" ) |

17 ( 0.67" ) |

M12x6 |

220 ( 8.66" ) |

|||||||||||||||||||||||||||||||

|

|

Max RPM |

Max Axial Force |

Adaptor size |

Net Weight |

|

JP-06L |

600 |

2250 kgf ( 4960 lbf ) |

Flat 140mm A2-5/A2-6 |

5.5 kgs |

|

JP-08L |

600 |

3500 kgf ( 7716 lbf ) |

Flat 170mm A2-5/A2-6/A2-8 |

8.0kgs |

|

Applications ◢ Spindle Grinding of DC Micro Motors ◢ Precise Bush ◢ Lens of Electronic Equipment ◢ Lens Frame of Smartphone ◢ Ceramics Grinding ◢ Cardiovascular stent ◢ Laser Carving, Laser Cutting, Laser Wielding ◢ Case of Stylus ◢ Wafer Board |

Example of Axial Stopper

|

CPC Power Collet Chuck (DIN6343 Collet)

CPC42/CPC-44/CPC-60/CPC-80

|

CPC power Collet Chuck

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CPD Precision Collet Chuck

CPD-5C/CPD-16C

CPD Dead-Length Collet Chuck

|

Product Features ◢ Adops 5C/16C collet ◢ 5C Collet:max. capacity 26mm ◢ 16C Collet:max. capacity 40mm |

JATO offers a blank drawnut when shipping the chuck.

Customers could thread the drawnut according to the drawtube of the machine.

CPD Collet Chuck Dimension

|

*The grey part shows in the drawing is a semi-ready draw-nut,the blank part is for user end to rework according to their thread size of draw tube* |

|||||||

|

( unit : mm ) |

|||||||

|

Model |

A |

B |

C |

D |

E |

F |

G |

|

CPD-5C |

138 ( 5.43" ) |

100 ( 3.94" ) |

M73xP1.5 |

72 ( 2.83" ) |

96 ( 3.78" ) |

100 ( 3.94" ) |

118 ( 4.65" ) |

|

CPD-16C |

M91xP1.5 |

80 ( 3.15" ) |

118.5 ( 4.67" ) |

90 ( 3.54" ) |

|||

|

Model |

Mounting Bolts |

Collet |

Ref. Cylinder |

Max. Pull Force |

Max. RPM |

Net Weight |

|

CPD-5C |

6H-M10 |

5C Collet |

JAL-636 |

1800 kgf ( 3968 lbf ) |

6000 |

5.4kgs ( 17.6 lbs ) |

|

CPD-16C |

6H-M10 |

16C Collet |

JAL-362 |

2300 kgf ( 5070 lbf ) |

5000 |

7.0 kgs ( 22.0 lbs ) |

|

fig.1 fig.2 fig.3 ( unit : mm ) |

|||||||||

|

Model |

Fig |

Spindle Nose |

A |

B |

C |

D |

E |

H |

I |

|

CPD-5C |

fig.3 |

A2-4 |

100 |

118 |

63.5 |

82.6 |

25 |

M10 |

M8 |

|

fig.3 |

A2-5 |

100 |

118 |

82.5 |

104.8 |

31 |

M10 |

M8 |

|

|

fig.3 |

A2-6 |

100 |

118 |

106.3 |

133.4 |

34 |

M12 |

M8 |

|

|

CPD-16C |

fig.3 |

A2-5 |

100 |

118 |

82.5 |

104.8 |

31 |

M10 |

M8 |

|

fig.3 |

A2-6 |

100 |

118 |

106.3 |

133.4 |

34 |

M12 |

M8 |

|

|

( unit : mm ) |

|||||||

|

Draw-back collet |

Max. Capacity |

||||||

|

Model |

d |

D |

L |

M ( Thread ) |

Round |

Square |

Hexagon |

|

5C |

31.75 ( 1.25" ) |

37.5 ( 1.48" ) |

87 ( 3.43" ) |

M31.5x20T |

26 ( 1.02" ) |

19 ( 0.75" ) |

23 |

|

16C |

48 ( 1.89" ) |

58 ( 0.28" ) |

114 ( 4.49" ) |

M47.5xP1.75 |

40 ( 1.57" ) |

28.2 ( 1.11" ) |

34.6 ( 1.36" ) |

5C Manual chuck

JMT-5C

|

Product Features ◢ They can be used for all turning, facing, boring, grinding, and milling operations on center lathes and grinding machines. ◢ The simple key operated scroll provides a uniform, distortion free clamping of the workpiece and low collet exchange time. |

|

Dimensions and Specifications

|

( unit : mm ) |

|||||||||

|

A |

B |

C |

D |

E |

F |

G |

H |

Mounting |

Net Weight |

|

126 ( 4.96" ) |

95 ( 3.74" ) |

26 ( 1.02" ) |

5 (0.2" ) |

107.5 ( 4.23" ) |

64 ( 2.52" ) |

87.9 ( 3.46" ) |

108 ( 4.25" ) |

3H-M8 |

4.1 kgs ( 9.0 lbs ) |

|

( unit : mm ) |

|||||||

|

Draw-back collet |

Max. Capacity |

||||||

|

Model |

d |

D |

L |

M ( Thread ) |

Round |

Square |

Hexagon |

|

5C |

31.75 ( 1.25" ) |

37.5 ( 1.48" ) |

87 ( 3.43" ) |

M31.5x20T |

26 ( 1.02" ) |

19 ( 0.75" ) |

23 |

|

5C Expanding Collet |