OTT-JAKOB Power Check II Checking the tool pull force

OTT-JAKOB HSK Gripper Pull Force Test Using Power Check 2

POWER-CHECK

OTT-JAKOB Power Check II for OTT-JAKOB Spindle Drawbars BT30 BT40 BT50 HSKA-53 HSKA-63 HSKA-100 Checking the tool pull force with the Power-Check 2 OTT-JAKOB HSK Gripper Pull Force Test Using Power Check 2

OTT-JAKOB Power Check II for OTT-JAKOB Spindle Drawbars BT30 BT40 BT50 HSKA-53 HSKA-63 HSKA-100 Checking the tool pull force with the Power-Check 2 OTT-JAKOB HSK Gripper Pull Force Test Using Power Check 2

OTT-JAKOB Power Check II for OTT-JAKOB Spindle Drawbars BT30 BT40 BT50 HSKA-53 HSKA-63 HSKA-100 Checking the tool pull force with the Power-Check 2 OTT-JAKOB HSK Gripper Pull Force Test Using Power Check 2

OTT-JAKOB Power Check II for OTT-JAKOB Spindle Drawbars BT30 BT40 BT50 HSKA-53 HSKA-63 HSKA-100 Checking the tool pull force with the Power-Check 2 OTT-JAKOB HSK Gripper Pull Force Test Using Power Check 2

POWER-CHECK

TRUST IS GOOD. MEASURING IS BETTER.

In machine tool technology, monitoring pull-in force as part of quality assurance is essential in order to guarantee consistently precise machining results. Too low clamping force can have a long-term impact:

- Poor surface quality due to vibrations

- Increased tool wear and shorter tool life spans

- Spindle taper corrosion caused by micro-movements

- Tool breakage

- Machine downtime

- Risk of injury to the machine operator

POWER-CHECK 2

POWER-CHECKMAGAZINE

RECEIVERS

POWER-CHECK 2

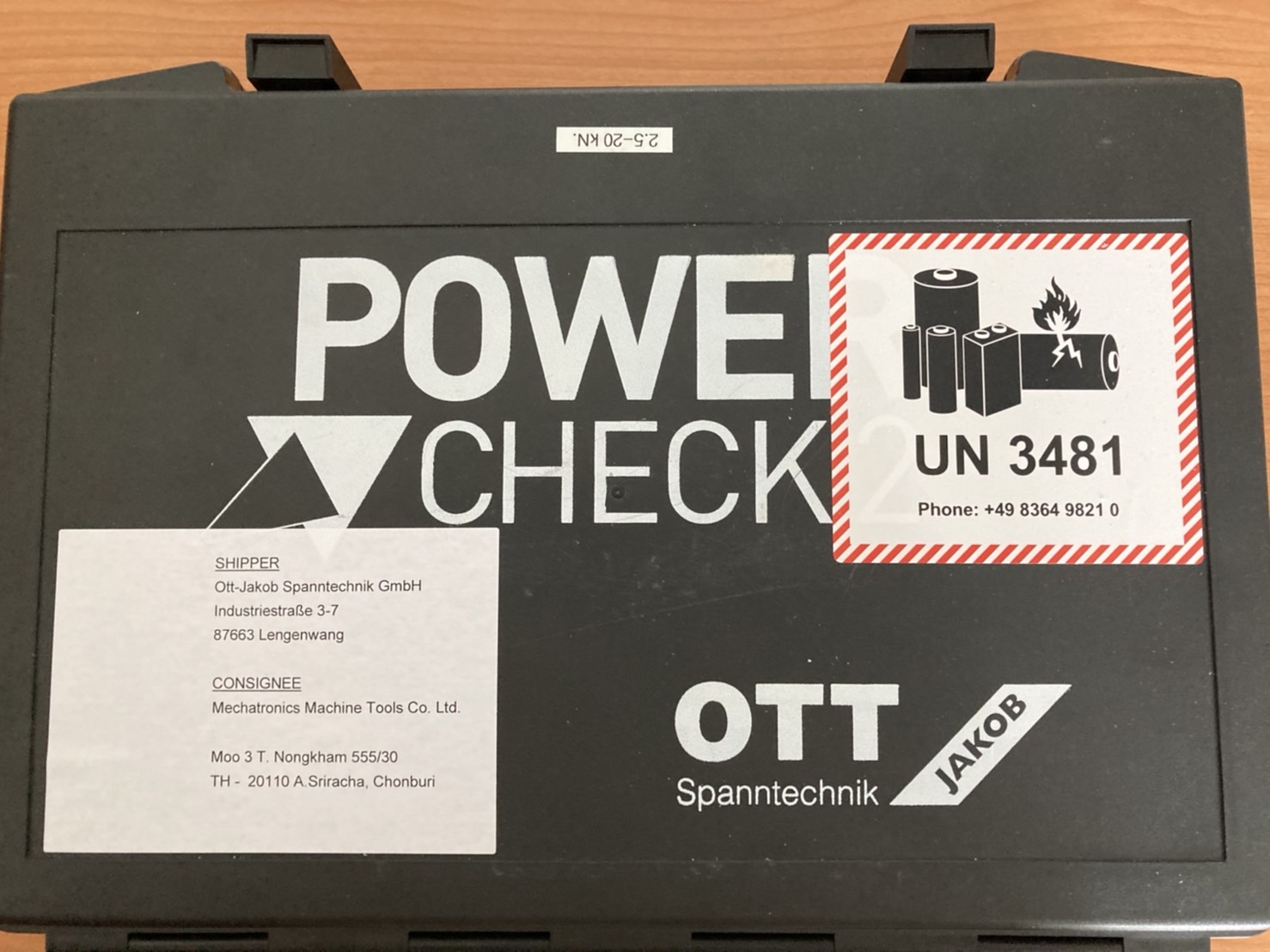

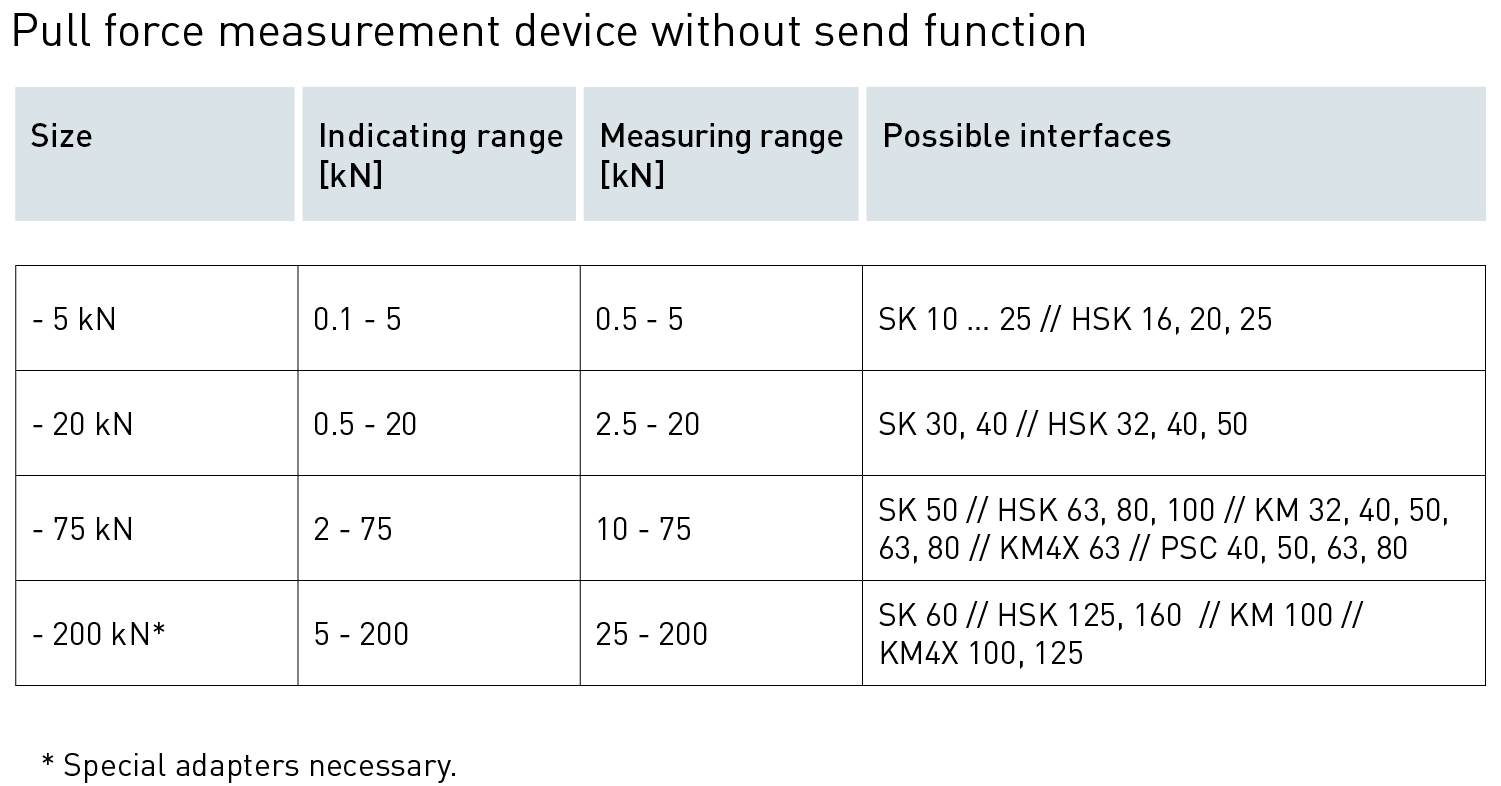

OTT-JAKOB Power-Check 2 is a testing device which measures the pull force of clamping systems. Four basic versions of the device are available, ensuring optimal measurement precision for every interface.

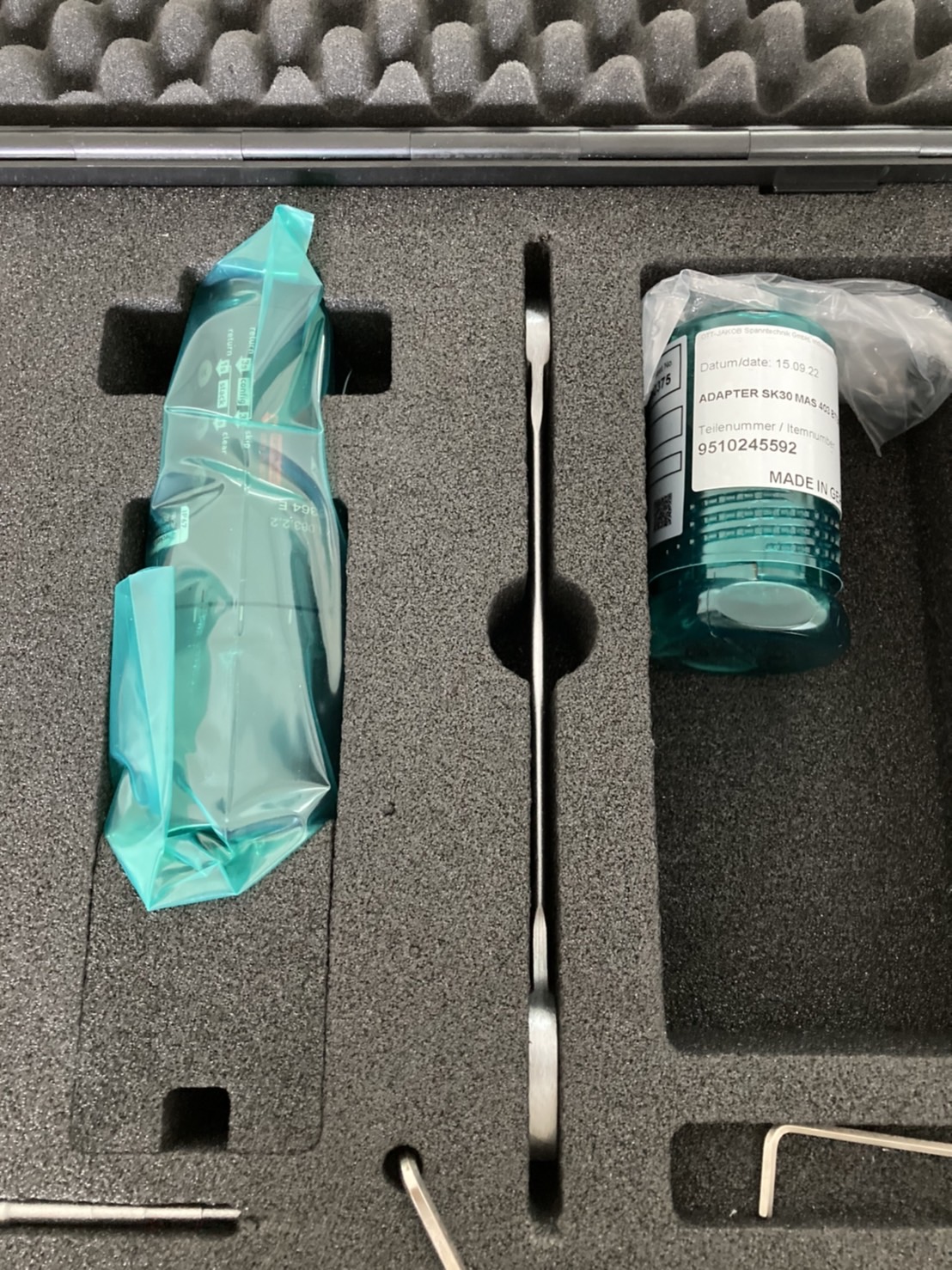

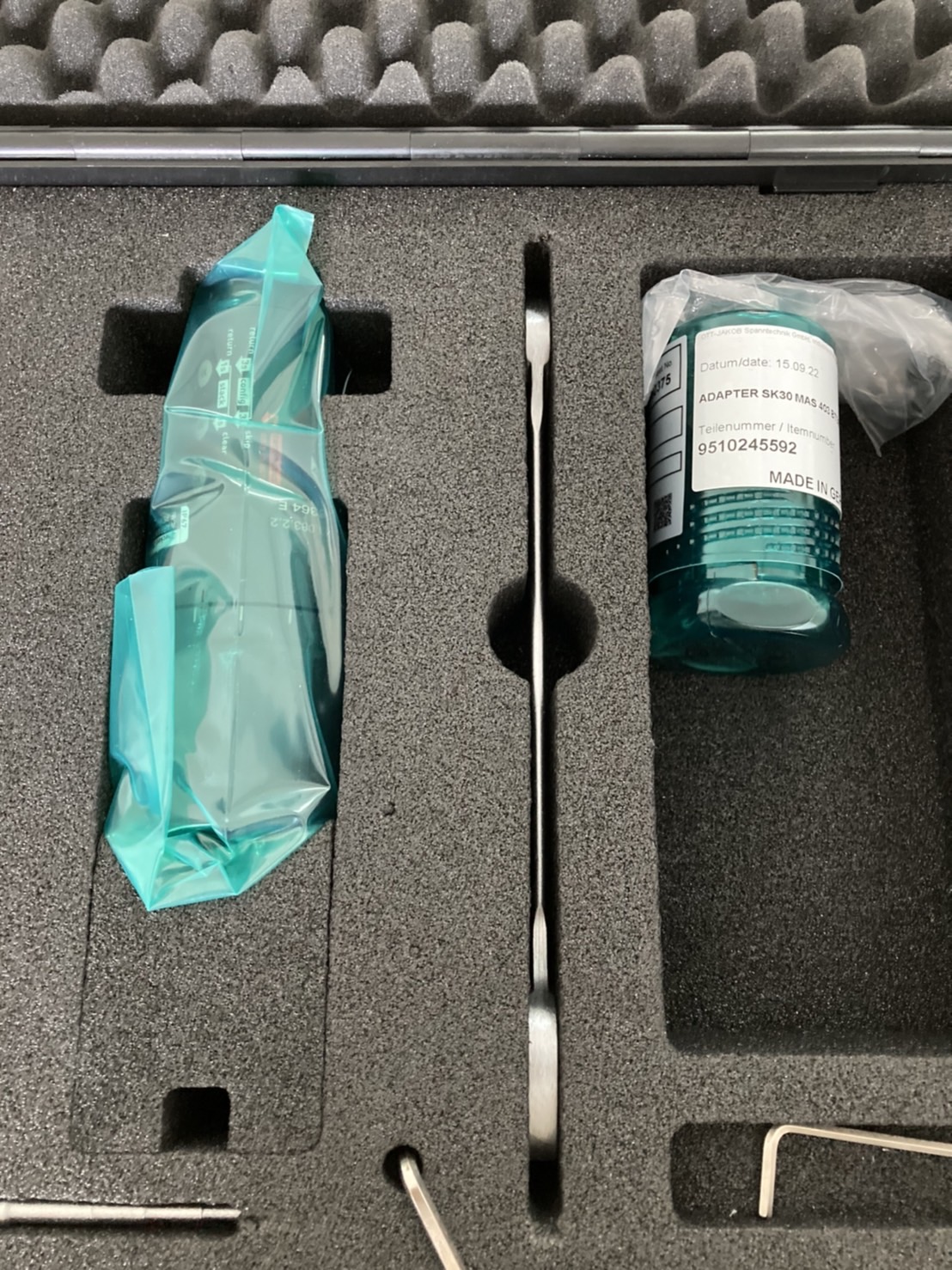

OTT-JAKOB has the right exchangeable adapter for all common tool interfaces. The product range also includes adapters with gripper grooves which make it possible to automatically switch in the tool from the magazine position. The Power-Check 2 can store up to 4,000 data sets which can easily be read out over a USB interface using the software supplied with the system. The built-in adjustable sleeve allows the user to account for tool tolerances during the measurement process. At the same time, this function can also be used to simulate the minimum and maximum tolerances of tools required to program the clamping system position monitor.

Here you can find more detailed information and documents abou