E-Catalog > WTO-DRIVEN TOOL > Turning Centers

Product Detail :

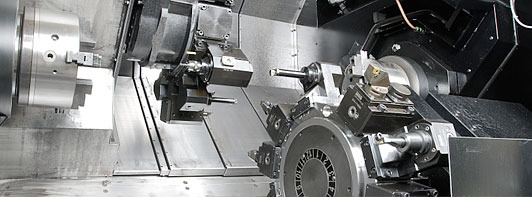

Turning Centers

Modern Turning Centers are using powerful turret drive motors to achieve high cutting performance for drilling and milling operations. With a WTO driven precision tool you are able to use the full power range of your machine. We offer solutions which are optimized for your machine type.

Static Toolholders

WTO offers a wide range of precision static toolholders. Our static toolholders are individually designed for each turning center and manufactured in highest precision that you are able using the full capacity of your machine.

Our static toolholders are manufactured according to the new ISO 10889 with highest care and accuracy. Each toolholder is made from high tensile strength steel, hardened, blacked and precision grounded.

Coromant Capto®

Coromant Capto® is a modular quick change system for turning centers certified according to ISO 26623. It combines highest stability and rigidity, at the same time highest flexibility in one system. Thanks to the short extension from the front of the spindle bearings and the long active distance between the spindle bearings you are able to reach higher cutting performance and better surface finish.

|

Why using Coromant Capto® toolholders?

|

|

QuickFlex® List of machines with QuickFlex® program

The perfect combination: ER collet chuck and quick change system in one toolholder.

|

|

1 - Toolholder

2 - QuickFlex® chuck 3 - Collet 4 - Collet nut 5 - QuickFlex® adapter 6 - One-hand wrench (patent registered) 7 - Thread for QuickFlex® adapter and collet nut 8 - Short taper for radial centering and axial support of the QuickFlex® adapter

9 - Taper of the ER collet chuck

10 - Polygonal torque transmission for QuickFlex® adapter 11 - Radial bending support of the QuickFlex® adapter for high stiffness

under load

|

|

|

Permanent accuracy of the run-out is guaranteed

by two independent taper connections. |

|

|

|

| With ER collet | With QuickFlex® mill arbor adapter |

|

|

|

Quick and safe tool change with the one-hand wrench (patent registered).

|

|

|

What are the benefits relating QuickFlex®?

You start with what you need first and you buy later the quick change adapters when you like to add the quick change function.

You can start with a basic system at low costs and later you add the quick change adapters.

The time for tool change can be significatly reduced.

Quick and safe tool change with the one-hand wrench (patent registered).

QuickFlex® - Superior handling/Quick change

Information

QuickFlex® is now available for DMG/MORI SEIKI turning centres from Gildemeister with Trifix® turret.

| Biglia: | |

| - B446, B465, B545, B565, B745, B765 | |

| Doosan: | |

| - Lynx 220 LMS | |

| - Lynx 220 M/LM | |

| - Lynx 300 M | |

| - Puma 230, 240, 280 M/MS/LM | |

| - Puma 300 M/MS | |

| - Puma 400, 480 M/LM | |

| - Puma 600, 700, 800 M/LM | |

| - Puma 1500, 2000, 2500 M/Y (12 ST, BMT55) | |

| - Puma 1500-2500 MS/SY (12 ST, BMT55) | |

| - Puma 2100 M/Y (12 ST, BMT55) | |

| - Puma 2100 M/MS/Y/SY (24 ST, BMT55) | |

| - Puma 2100, 2600 M/Y (12 ST, BMT65) | |

| - Puma 2100, 2600 MS/SY (12 ST, BMT65) | |

| - Puma 2100, 2600 M/MS/Y/SY (24 ST, BMT65) | |

| - Puma 3100 M/CM/Y/MY (12 ST, BMT65) | |

| - Puma Inverturn 3000 M | |

| - Puma MX1600 ST (BMT45) | |

| - Puma MX1600, 2100 ST (BMT55) | |

| - Puma MX2000, 2500, 2600 T/ST/SY | |

| - Puma TL2000, 2500 M | |

| - Puma TT1500, 1800 MS/SY | |

| - Puma TT2000, 2500 MS/SY | |

| - Puma V400 M | |

| - Puma V550 M | |

| - Puma VT1100 M | |

| - Puma VT450 M, VT450 M-2SP | |

| - Puma VT750 M, M-2SP | |

| - Puma VT900 M, M-2SP | |

| Ecoca: | |

| - MT-3/MT-4 MC/MCSY | |

| EMAG: | |

| - VL 2 LE (BMT55) | |

| - VT 2, VTC 100-4, VL 2 P (BMT55) | |

| - VT 4 (BMT65) | |

| EMCO: | |

| - Hyperturn 65 (BMT55) | |

| - Maxxturn 65-1050 M/MY/SM/SMY (BMT55) | |

| FOCUS: | |

| - CNC FBL-510 - 540MC | |

| Gildemeister: | |

| - CTX beta VDI40 Trifix® | |

| Goodway: | |

| - GLS-1500, 2000 M | |

| - GMT-2000 | |

| - GS-2000 - 2800 (16-fach Revolver/16 stations turret) | |

| - GS-3000 - 3600 alpha | |

| - GTS-200, 260 | |

| - GTX-2000 (12-fach Revolver/12 stations turret) | |

| - GV-500, 780 M | |

| Hardinge: | |

| - T-42 M/MT/MY/MYT/MS/MSY | |

| - T-51, 65 M/MT/MY/MYT/MS/MSY | |

| Hwacheon: | |

| - Cutex 160 MC/SMC | |

| - Cutex 240 MC/SMC | |

| - Hi-Tech 200 MC | |

| - Hi-Tech 450 MC/SMC/YMC/YSMC | |

| - Hi-Tech 550 MC | |

| - T2 MC/SMC/YMC/YSMC | |

| - VT 450 MC (BMT65) | |

| - VT 550 MC | |

| - VT 950, 1150 MC | |

| Hyundai: | |

| - WIA L230LMSA | |

| - WIA L300M/MS | |

| - WIA L400MA/MC/LMC | |

| - WIA L600, 700M/LM | |

| - WIA L2100SY | |

| - WIA LM1600, 1800TTSY | |

| - WIA LM2000, 2500TTM/TTMS/TTSY | |

| - WIA LV800RM / SKT-V80R/RM | |

| - WIA LV1100RM | |

| - WIA SKT160, 180TTMS/TTSY (BMT55) | |

| - WIA SKT200, 250TTM/MS/SY | |

| - WIA SKT250, 300M/MS | |

| - WIA SKT400M/LMC | |

| - WIA SKT600, 700LM | |

| Jyoti: | |

| - TMC 250, 350 (BMT45) | |

| Mazak: | |

| - Quick Turn Smart 100, 150 M S | |

| - Quick Turn Smart 200, 250 M | |

| - Quick Turn Smart 300, 350 M | |

| Mori Seiki: | |

| - DuraTurn 2050, 2550 MC | |

| - NL/NLX 1500-4000 MC/Y/SMC/SY | |

| - NL/NLX 1500-2500 (20-fach Revolver/20 stations turret) | |

| - NLX 4000 (High Torque Milling) | |

| - NT/NTX 1000, 2000 | |

| - NT 3100, 3150, 3200 | |

| - NT 4200-5400 | |

| - NZ/NZX 1500-2500 (16-fach Revolver/16 stations turret) | |

| - NZX 2500 (12-fach Revolver/12 stations turret) | |

| - NZX 4000 | |

| - NZX 6000 | |

| Okuma: | |

| - GENOS L300 MW/MYW | |

| - LB/LU 2000-3000 EX M/MY/MW/MYW | |

| - LB 4000 EX M/MY | |

| - LT 2000 EX M/MY (16-fach Revolver/16 stations turret) | |

| - LT 3000 EX M/MY | |

| Samsung: | |

| - SL/PL-20, 25 MC | |

| - PL-45 MC | |

| Takisawa: | |

| - TY-2000 (HPI Revolver/turret) | |

| - Taiwan EX 308, 310, 708, 710 | |

| - Taiwan EX/NEX 508, 510, 908, 910 | |

| - Taiwan LA 200, 250 M/Y | |

| Tongtai: | |

| - TNL-120T | |

| Victor: | |

| - VTurn-A16/20CM, SCM, YCM, YSCM | |

| - VTurn-A26CM, SCM, YCM, YSCM | |

| - VTurn-Q200 | |

| YCM: | |

| - NT-2000, 2500 Y/SY | |

| - TC-46 M | |

WT-System

WTO offers with the WT-System a complete program of driven tool holders with its own modular quick change system. Using interchangeable and presetable spindles you can reduce the set-up time remarkably.

Features

- High precision and repeatability

- Modular presatable spindles

- High rigidity using a clamping nut

- Fast and easy tool change using a one-hand-wrench

- Very short and compact design

|

|