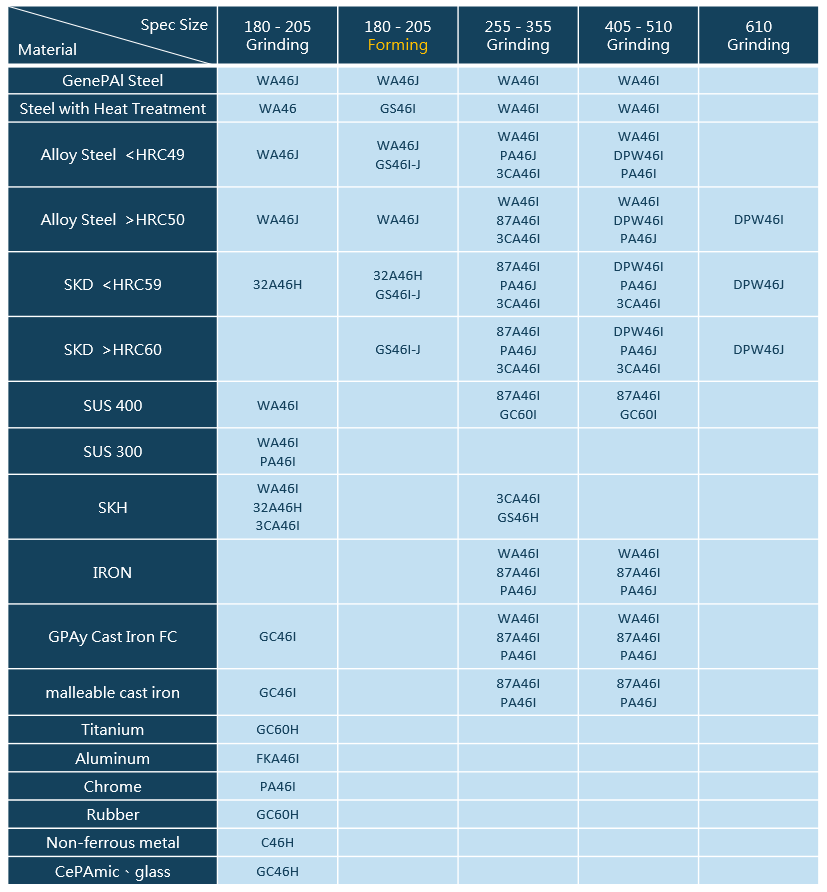

Horizontal spindle surface grinding wheel

- It is well suited for a horizontal shaft-grinding machine. Processing manners depend on a practical demand to use for surface or profile grinding.

- High Stock-Removal Ratio, High Precision and High Efficiency.

- Applicable to each type of hard-to-grind work piece (HRC25o ~ HRC64o).

Vertical spindle surface grinding wheel

Segments, cup or cylinder wheels allow greater grinding contact areas than other forms or grinding operations.

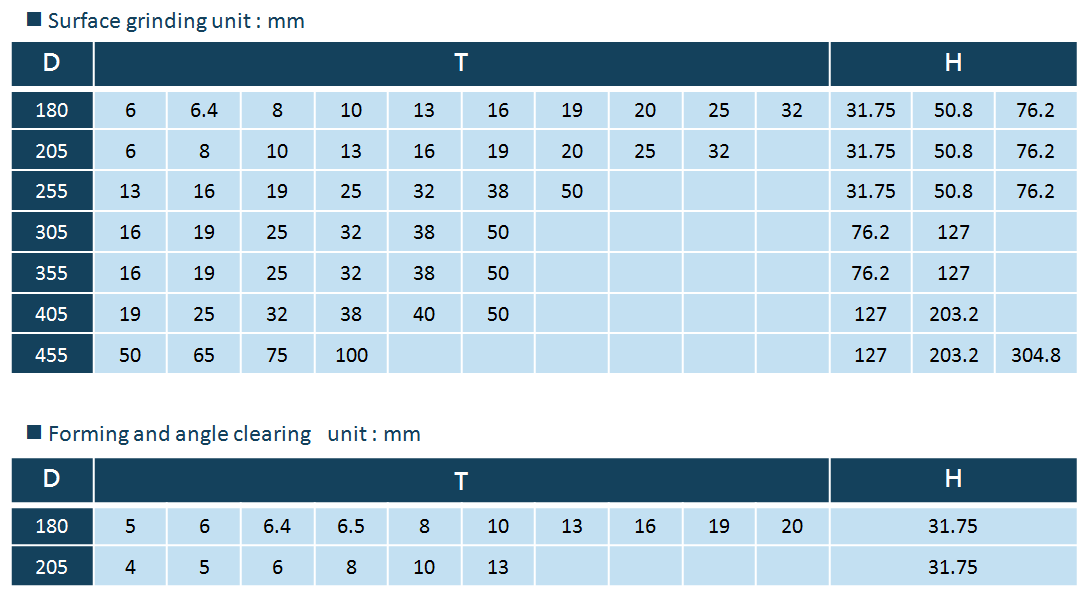

Regular specification of surface grinding wheel(include angle clearing)

Size : Diameter (mm)

Regular size of surface grinding wheel(include angle clearing)

Vertical spindle surface grinding wheel

Segments, cup or cylinder wheels allow greater grinding contact areas than other forms or grinding operations.

- Carbo Vertical Shaft Surface Grinding Wheel is based on an end grinding of ring and cup wheel.

- A contact area for vertical shaft surface grinding wheel and work piece is large. The amount of stock-removal for work piece is more than other types of surface grinder, suitable for larger stock-removal work piece or mass production