Safecontrol 4.0 - an important component for quality assurance and process reliability within your production

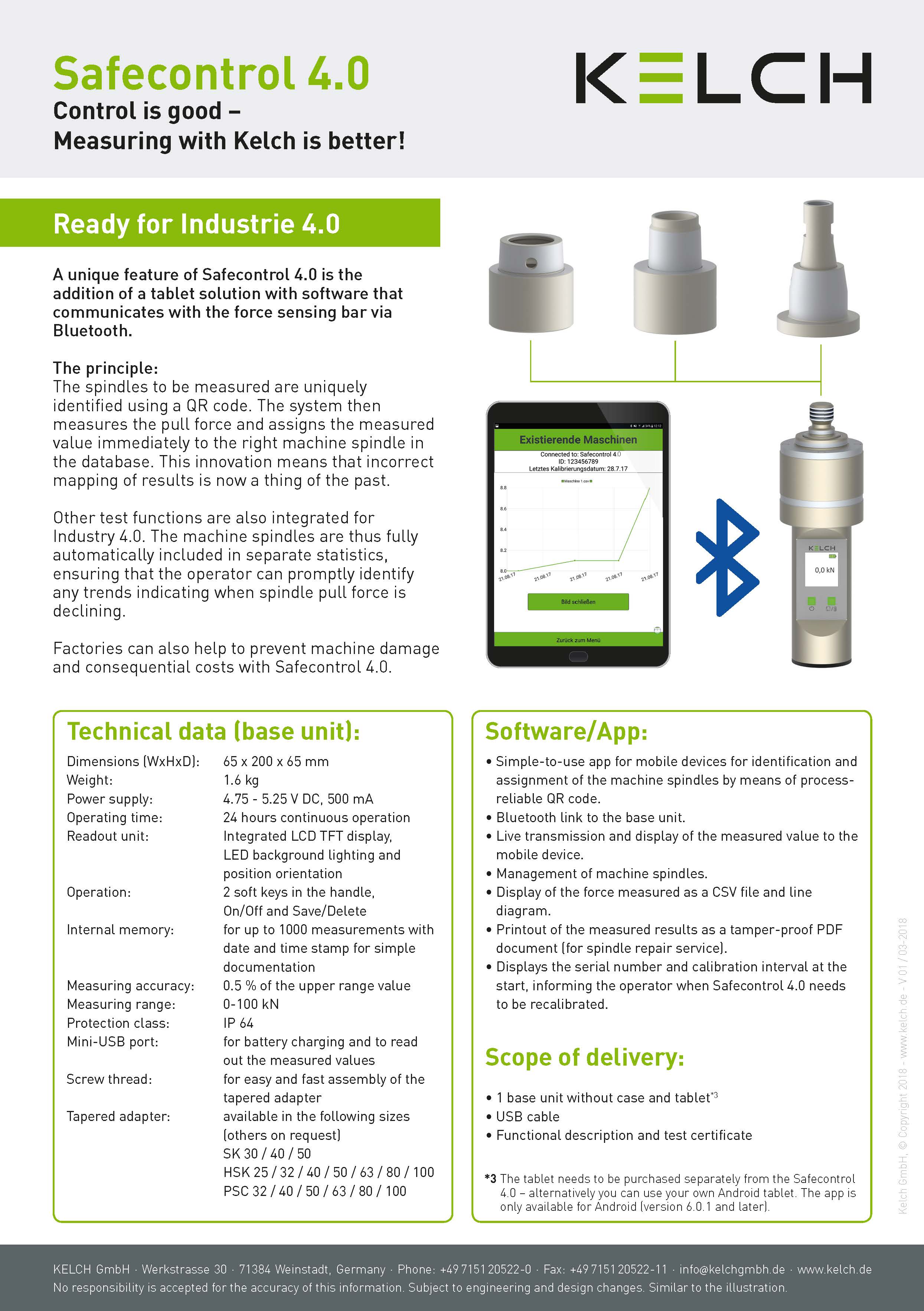

Safecontrol 4.0 is equipped with all the latest technology to integrate seamlessly with your other Industry 4.0 production systems. The system benefits from non-contact BlueTooth technology, QR Code spindle identification and an Android app to manage the data on your phone or tablet. The optional ruggedised tablet PC completes the set and allows instant logging and reviewing of all your spindle pull force data.

.jpg)

No need for individual sensing bars for each spindle type. One sensing bar with the different adaptors, reduces the cost and means only one item needs calibrating.

Other benefits include guaranteed machining quality and accuracy, reduced reject rates and machine down-time, with improved operator safety and process reliability.

Safecontrol 4.0 Features:

- Only one Base unit for all tool holder types (HSK, PSC, SK etc.)

- Easy to use base unit

- Display has 3D Sensor for rotating the display content

- Big measuring range (1-100kN)

- High accuracy (Base unit < 1 % from measuring range end value)

- Protection class IP 64

- Ready for Industrie 4.0

- Displaying the value in the Kelch APP on a Tablet or Smartphone via Bluetooth

- A ruggidized tablet suited to the environment of a CNC machine shop available

- App can be used for managing the machines and spindles and in combination with scanning a QR code it is 100% process reliable

- Automatic storage of the measured values according to the right machine

- Calibration over the complete measuring range (0-100 KN)

Safecontrol 4.0

Technical Information

- Dimensions: 65 x 200 x 65 mm (Base unit)

- Weight: 1.6kg (Base unit)

- Measuring range: 1-100kN

- Measuring accuracy: ≤ 1% from measuring range end value

- Protection class: IP 64

- Battery information: 4,75 - 5,25 V DC, 500 mA Litium-Ionen

- Operating time: > 24 Std.

- Display: LCD TFT-Display with LED backlight and position sensor

- Only 2 buttons for operation (ON / OFF + SAVE / DELETE)

- Internal memory for up to 1000 measurements with date and time stamp

.jpg)