PAGE VIEW : 1,937

Product Information :

Name :

ATC Alignment Tool Set Category :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

Sub - Category :

- SYIC

Brand :

SYIC Product Product Type :

- สินค้า, ผลิตภัณฑ์

Short Description :

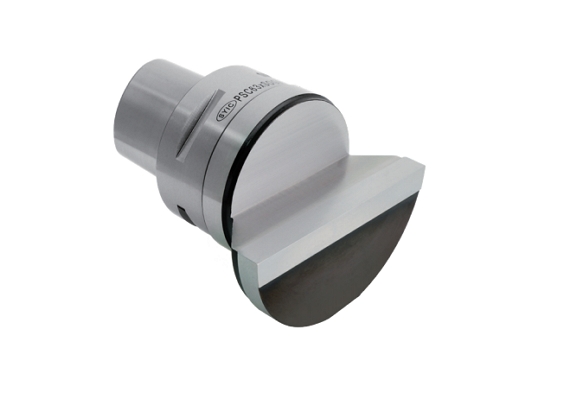

SYIC Product Highlights ATC Alignment Tool Set Measuring Tool For Machining Cente

Product Detail :

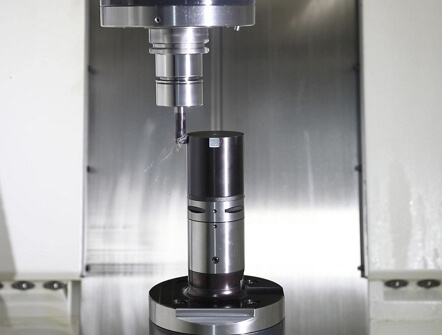

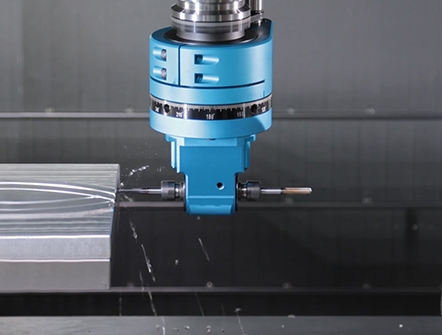

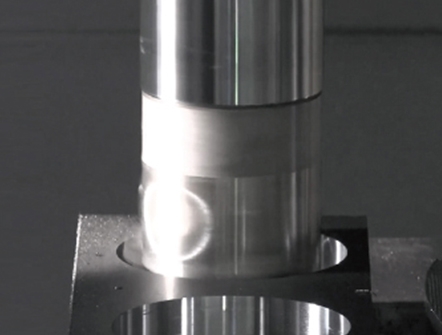

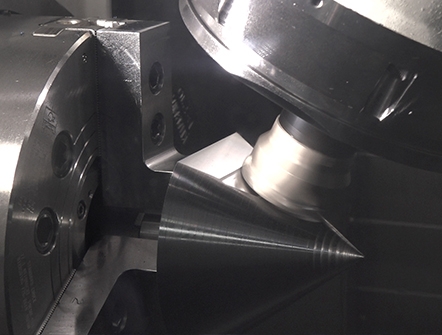

SYIC Product Highlights ATC Alignment Tool Set

https://mail.surenotifyapi.com/v1/t/c?s=0&x=20230714021412-1-b5a70452-7ab7-4557-9dbf-d09a5a21a7d5

https://www.syic.com/proimages/E-Catalog/pdf/20230323/NO.2020-08-ATC-alignment-tool-set.pdf

|

Guardian of Machine Accuracy

|

ATC Alignment Tool Set

Products