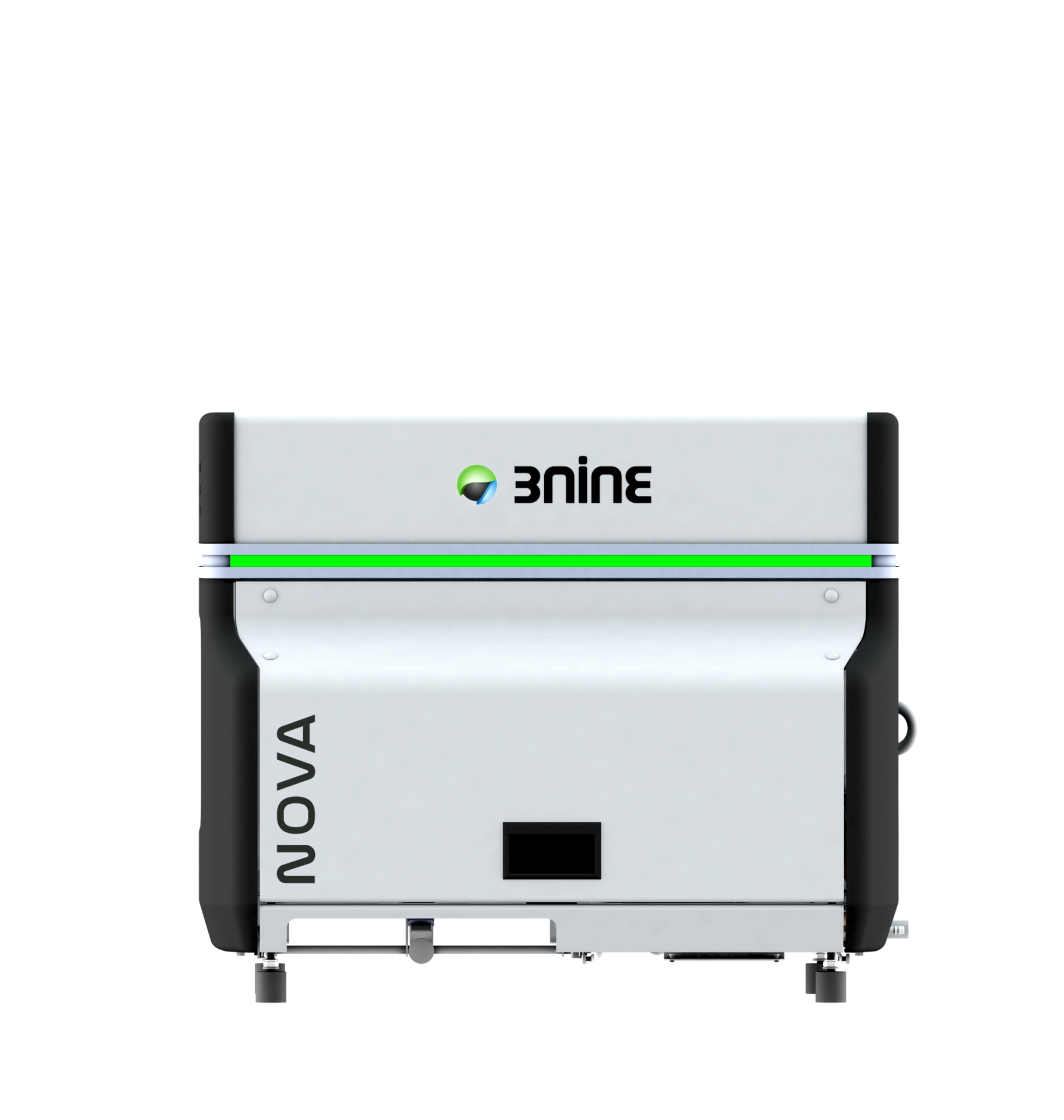

The Nova is the smallest oil mist eliminator in the GREEN LINE series and works on all machine tools with a cabin volume of up to 70 CF (2 m³).

The Nova will effectively clean the oil mist/oil smoke formed during processing on your smaller machine tools. Besides getting clean air in the workshop, the Nova will also recycle almost all of your oil or coolant for reuse.

The Nova is available in two versions – Advanced and Basic. The Nova Advanced is controlled by a frequency converter which incorporates more advanced monitoring of the HEPA-filter, pressure drops and the drive belt, as well as controls the CIP system. The Nova Basic is controlled by a built-in circuit breaker and has a pressure switch that monitors the HEPA-filter.

| Application |

Cleaning oil mist (cutting fluid/coolant) from the workshop environment |

|---|---|

| Mounting |

Directly on top, On a pillar stand, On a wall/column stand |

| Max cabin size |

<2m3 |

| Airflow |

300m3/h |