E-Catalog > SMW AUTOBLOK > APS Zero Point Clamping System

Product Detail :

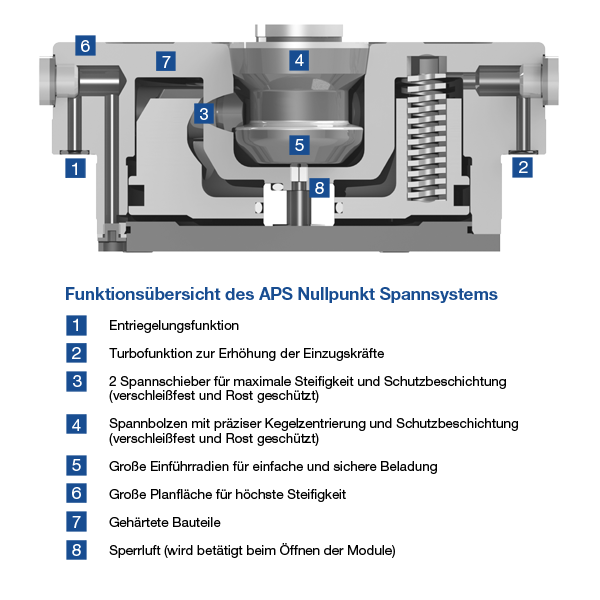

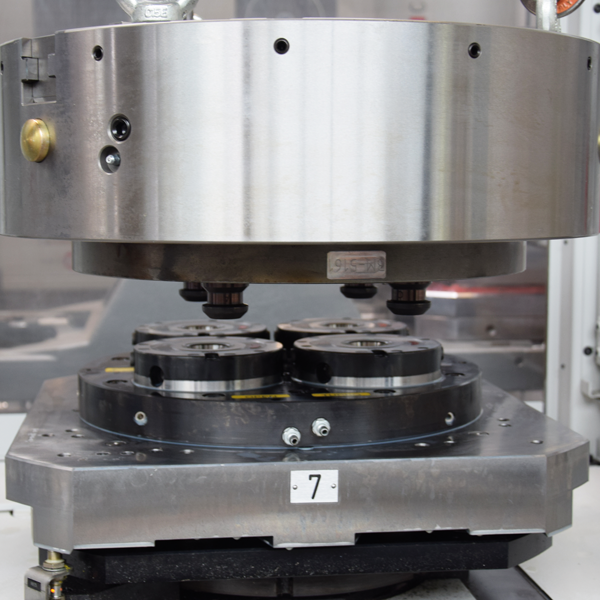

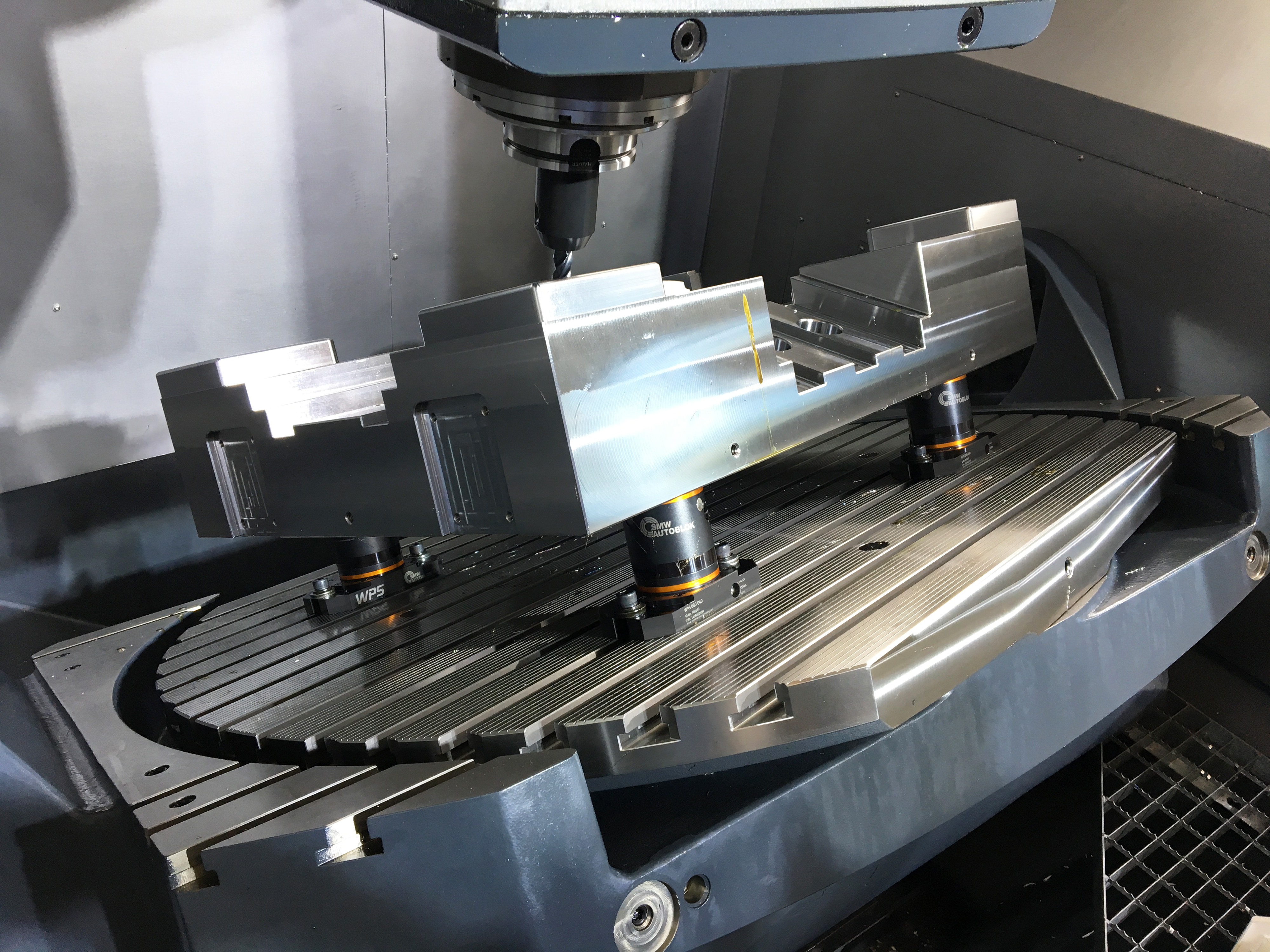

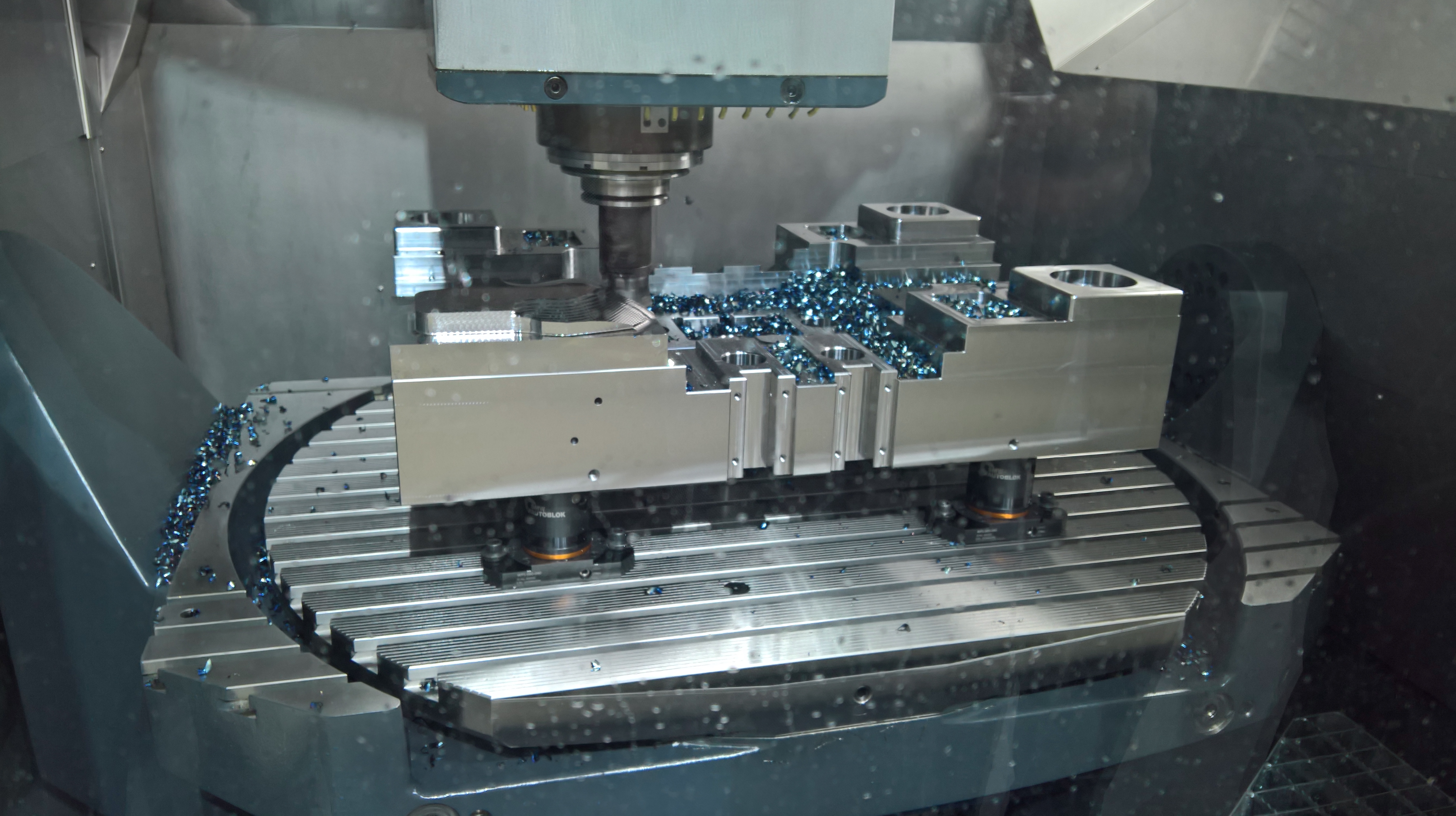

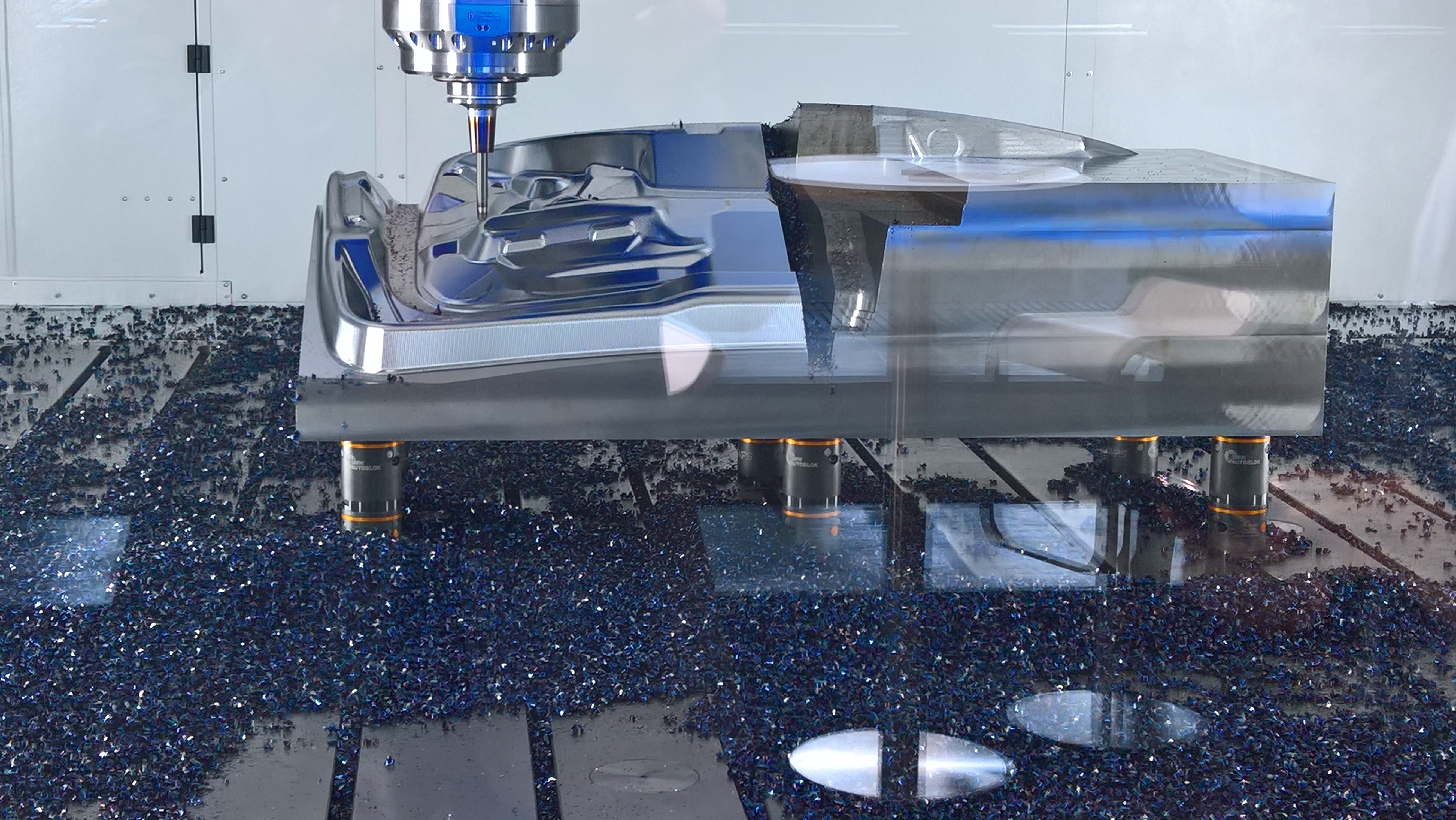

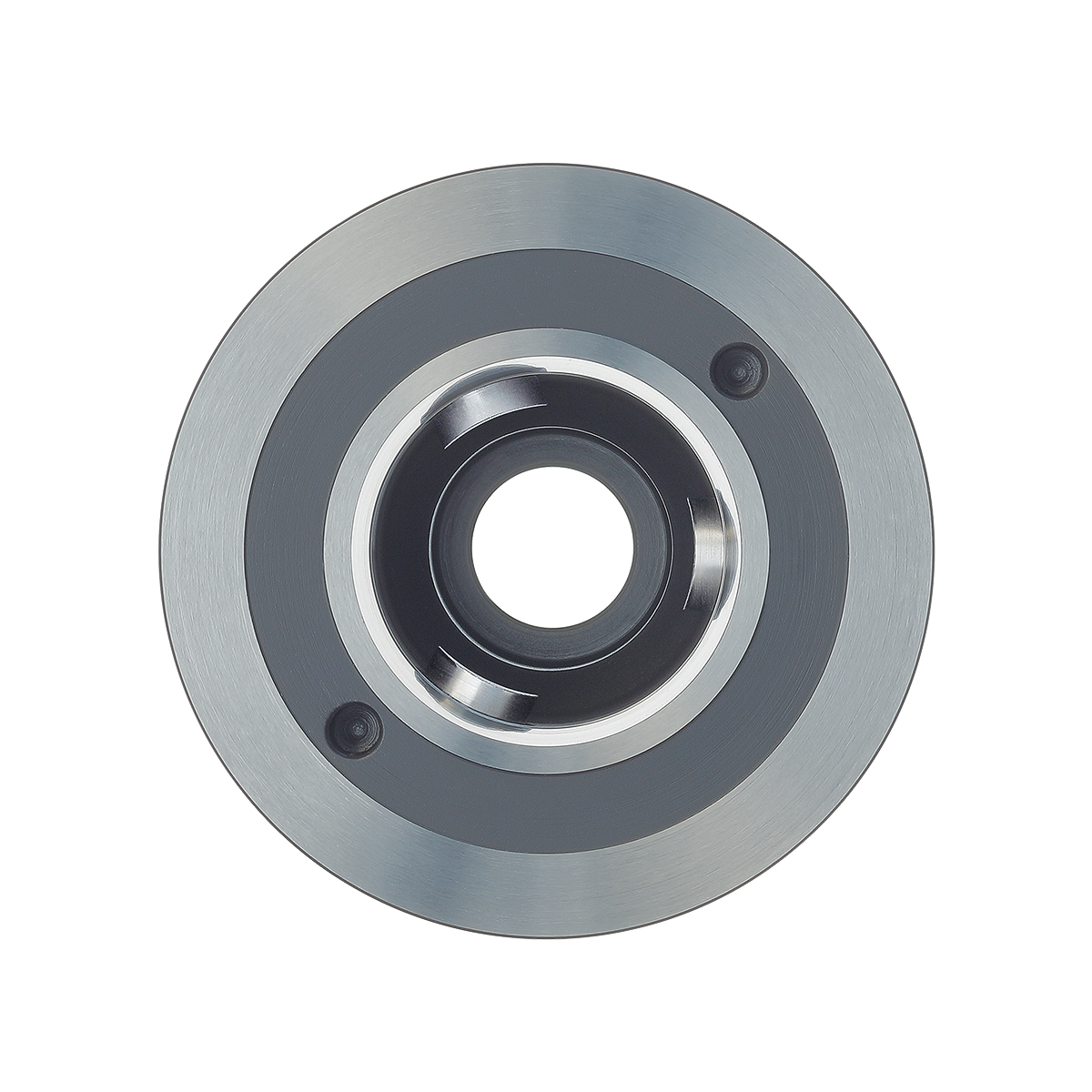

APS Zero Point Clamping System

With the new APS zero point clamping system, users can reduce set-up times by up to 90%.

The APS zero point clamping system can be used in all operations such as turning, milling,

measuring, eroding or grinding. This means users benefit from significantly reduced costs due

to reduced set-up times while increasing the availability of machines throughout the production line.

3 different ranges – Basic, Premium and Top – offer optimum solutions for all application requirements.

- Significantly reduced costs due to reduced set-up times

- Modular construction kit system: existing clamping systems can be modified very easy

- Low installation height due to the compact design

- Highest process reliability and repeat accuracy < 0.005 mm

- Wear-resistant and protected against rust (or stainless) due to heat treated elements and an extra hard protective coating

- Maximum pull-in forces until 45 kN (APS 190) thanks to turbo function

- Highest stiffness by means of 3 clamping slides (Premium / Top-Version)

- Fully sealed (proofline)

- Interchangable to the Workpiece Positioning System WPS

Produktvideo

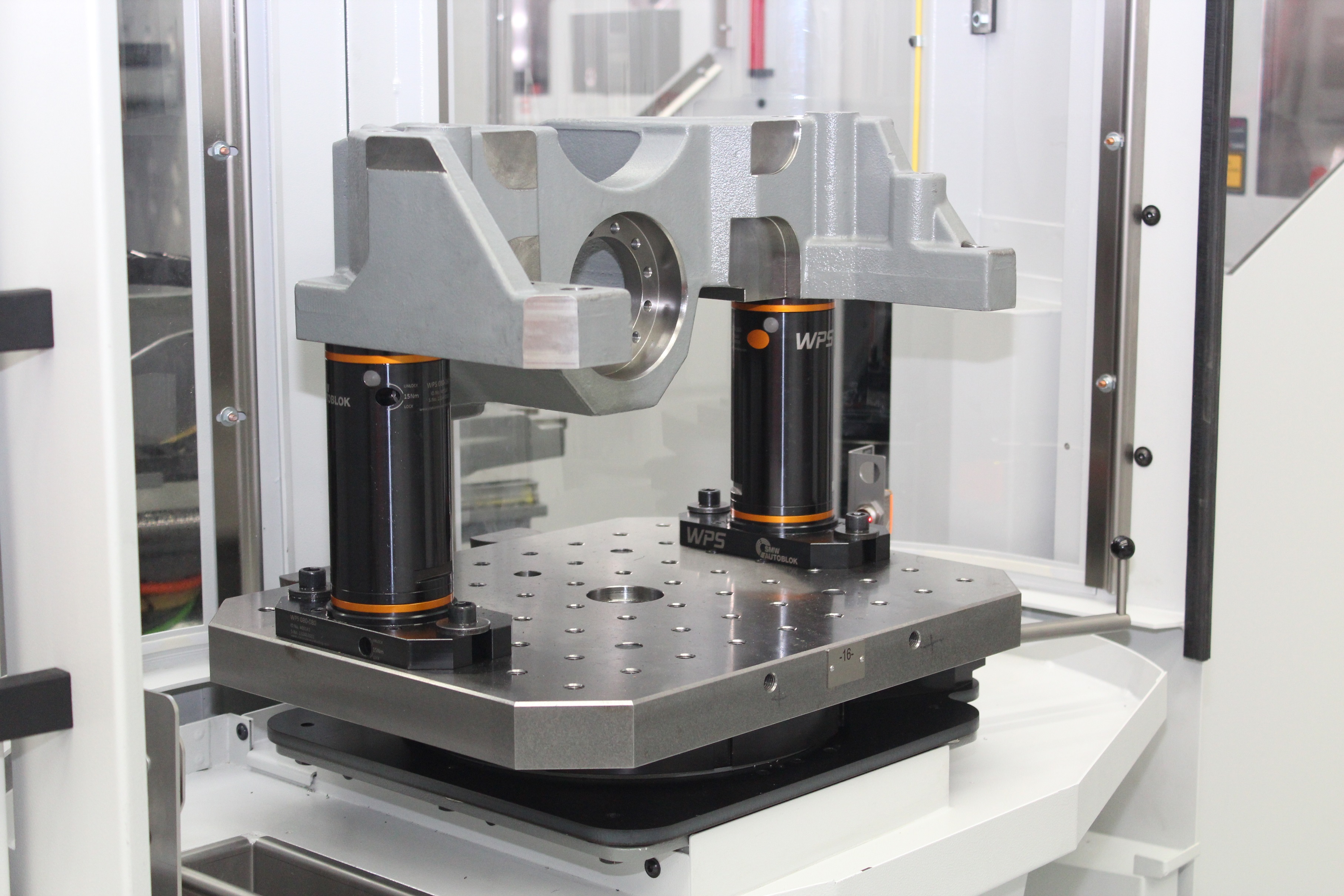

WPS WORKPIECE POSITIONING SYSTEM

Manual Zero Point Clamping System for the Workpiece Direct Clamping

- Huge reduced set-up times for highest efficiency

- Safe workpiece clamping with maximum holding forces and highest repeatability

- Ideal for 5-axis machining

- Single quick-actuation for the rapid opening and closing of the modules with only 3.5 rotations

- Flexible configurations for customized use

- Interchangeable to the proven zero point system APS

technical data

- Diameter 80 mm

- Pull-in force 15 kN

- Repeatability < 0.005 mm

- Holding force 50 kN

- Proofline® = fully sealed - low maintenance

Workpiece preparation for the mounting of the clamping pins

3D-Files: Workpiece preparation for the easy integration by the customer ![]()

Step, IGES, Solid Works, Feature for automatic import in the 3D system (only Solid Works)