E-Catalog > TAC Rockford for machine Tools > Machine Tool Gauges : Turning Center

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- TAC Rockford for machine Tools

- สินค้า, ผลิตภัณฑ์

Product Detail :

Turning Center Gauges

Chuck Force

The ForceCheck wireless chuck force gauge is designed to quickly and accurately measure holding force and speed on chucks. Verifying chuck holding force allows manufacturers to improve the repeatability of a manufacturing process by checking actual holding force under dynamic (rotating) conditions, as well as perform critical preventative maintenance checks. Contact us for other clamping diameters and extension rings, as well as 4+ jaw chucks.

Dimensional Measuring

Series 492.026 ring gauges are for lathe spindle face. Series 492.028 plug gauges are for chuck back side mounting face. Taper gauges can be custom-manufactured to customer specifications. Hard chrome-plate and tungsten carbide gauges

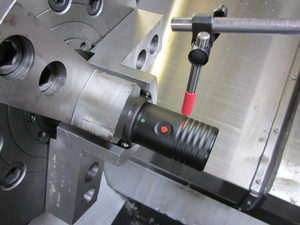

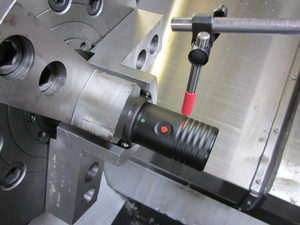

ForceCheck Turning-Center Chuck Force Gauges

Turning-center force sensors are designed to measure the holding force of clamp jaws on chucks. This allows manufacturers to make critical adjustments, and improve repeatability and workpiece quality. The wireless version of the chuck force gauge is able to measure RPM along with force.

For more advanced features, such as graphing and testing multiple machines as part of a preventive maintenance plan, a tablet that universally connects to any ForceCheck sensor is also available. Contact us for more specifications and details on advanced machine force measuring.

Wireless Chuck Force Gauges

The ForceCheck wireless chuck force gauge is designed to quickly and accurately measure holding force and speed on chucks. Verifying chuck holding force allows manufacturers to improve the repeatability of a manufacturing process by checking actual holding force under dynamic (rotating) conditions, as well as perform critical preventative maintenance checks. Contact us for other clamping diameters and extension rings, as well as 4+ jaw chucks.  Details

Details  PDF (495.320)

PDF (495.320)

Wired Chuck Force Gauges

Designed to quickly check the holding force on a chuck or turning-center. The wired chuck force gauge can be customized for any diameter.  Details

Details  PDF (495.205)

PDF (495.205)

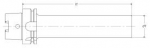

Runout Test Bars for Lathes, Chucks, and Turning Centers

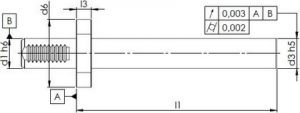

VDI Runout Test Bars

Runout testing bar for VDI interface. Used for both testing run-out of the interface as well as center alignment and adjustment on a lathe. Made to DIN 69880 standard.  Details

Details  PDF (465.V00)

PDF (465.V00)

| DIN 69880 | d1 | d3 | d6 | L1 | L3 | Order Number | ||

|---|---|---|---|---|---|---|---|---|

| VDI 20 | 20 | 40 | 50 | 150 | 15 | 465.V20.000.000

|

||

| VDI 25 | 25 | 40 | 58 | 150 | 15 | 465.V25.000.000

|

||

| VDI 30 | 30 | 40 | 68 | 200 | 15 | 465.V30.000.000

|

||

| VDI 40 | 40 | 40 | 83 | 200 | 15 | 465.V40.000.000

|

||

| VDI 50 | 50 | 40 | 98 | 200 | 15 | 465.V50.000.000

|

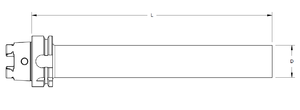

Runout Test Arbors for Turning Centers

TAC Rockford runout arbors for lathe centers are manufactured using hardened gauge-quality steel, and include a certificate of accuracy.  Details

Details  PDF (490.520)

PDF (490.520)

| Description | Length (mm) | Diameter (mm) | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| Runout Arbor for Centers | 300 | 32 | 490.520.032.300

|

|||||

| Runout Arbor for Centers | 400 | 35 | 490.520.035.400

|

|||||

| Runout Arbor for Centers | 250 | 40 | 490.520.040.250

|

|||||

| Runout Arbor for Centers | 500 | 40 | 490.520.040.500

|

|||||

| Runout Arbor for Centers | 600 | 50 | 490.520.050.600

|

|||||

| Runout Arbor for Centers | 500 | 63 | 490.520.063.500

|

|||||

| Runout Arbor for Centers | 700 | 70 | 490.520.070.700

|

|||||

| Runout Arbor for Centers | 1000 | 80 | 490.520.080.01K

|

|||||

| Runout Arbor for Centers | 750 | 80 | 490.520.080.750

|

|||||

| Runout Arbor for Centers | 1000 | 90 | 490.520.090.01K

|

|||||

| Runout Arbor for Centers | 800 | 90 | 490.520.090.800

|

Runout Test Arbors for Chucks

TAC Rockford manufacturers runout arbors for chucks as a special order item. Please contact us for further information.  Details

Details  PDF (490.510)

PDF (490.510)

Lathe Spindle Face Ring and Taper Plug Gauges

For measuring the dimensions of lathes and chucks

Series 492.026 ring gauges are for lathe spindle face.

Series 492.028 plug gauges are for chuck back side mounting face.

Taper gauges can be custom-manufactured to customer specifications. Hard chrome-plate and tungsten carbide gauges also available.

Cases are not included. Contact us for high quality gauge crib and travel case options.

| Standards | Size | d2 max. | d2 min. | Gauge | Order Number | |||

|---|---|---|---|---|---|---|---|---|

| DIN55026-3, DIN55027-3, A1-3, A2-3, B1-3, B2-3 | 3 | 53.983 | 53.975 | Ring | 492.026.003.000

|

|||

| DIN55026-4, DIN55027-4, A1-4, A2-4, B1-4, B2-4 | 4 | 63.521 | 63.513 | Ring | 492.026.004.000

|

|||

| DIN55026-5, DIN55027-5, A1-5, A2-5, B1-5, B2-5 | 5 | 82.573 | 82.563 | Ring | 492.026.005.000

|

|||

| DIN55026-6, DIN55027-6, A1-6, A2-6, B1-6, B2-6 | 6 | 106.385 | 106.375 | Ring | 492.026.006.000

|

|||

| DIN55026-8, DIN55027-8, A1-8, A2-8, B1-8, B2-8 | 8 | 139.731 | 139.719 | Ring | 492.026.008.000

|

|||

| DIN55026-11, DIN55027-11, A1-11, A2-11, B1-11, B2-11 | 11 | 196.883 | 196.869 | Ring | 492.026.011.000

|

|||

| DIN55028-3, DIN55029-3 | 3 | Plug | 492.028.003.000

|

|||||

| DIN55028-4, DIN55029-4 | 4 | Plug | 492.028.004.000

|

|||||

| DIN55028-5, DIN55029-5 | 5 | Plug | 492.028.005.000

|

|||||

| DIN55028-6, DIN55029-6 | 6 | Plug | 492.028.006.000

|

|||||

| DIN55028-8, DIN55029-8 | 8 | Plug | 492.028.008.000

|

|||||

| DIN55028-11, DIN55029-11 | 11 | Plug | 492.028.011.000

|

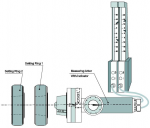

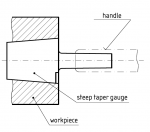

Steep Taper Spindle Plug Gauges

TAC Rockford gauges are used for inspection of steep taper spindle tapers per CAT, ISO, JIS, DIN, etc. Available for Steep Taper 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60,...

Drive Key Spindle Gauges

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face. Two measuring gauges in storage case:...

Electronic Tool Taper Gauges

The four transducers mounted in the measuring ring are used for differential measurement of gauge dimensions d2 and d3. Deviations from the calibrated taper plug gauge are...

Dial Indicator Tool Taper Gauges

Both measuring gauges are set to zero with the calibrated taper plug gauge. When an HSK tool holder is inserted in the ring gauges, deviations in diameters d2 or d3 are shown...

Tool Holder Taper Sleeve Gauges

Available for Steep Taper CAT/ANSI/DIN/BT/ISO 10, 15, 20, 25, 30, 35 40, 45, 50, 55, 60, 65

Dial Indicator Spindle Taper Gauges

To ensure sustained accuracy at HSK interfaces, we recommend comparison measuring of the geometry of HSK tool shanks and spindles at regular intervals. These checks should...

Morse Spindle Taper Plug Gauges

TAC Rockford Morse spindle taper gauges are for inspection of Morse spindle tapers. Gauges made from a hardened gauge steel, and include a padded carrying case and certificate....

Pneumatic Spindle Taper Gauges

Non-contact measuring with nozzles results in high accuracy and consistency of measuring results. The measuring range can be increased with the built-in dial indicator. This...

Steep Taper Spindle Gauge Manual

Download PDF for instruction manual.

ForceCheck Turning-Center Chuck Force Gauges

Turning-center force sensors are designed to measure the holding force of clamp jaws on chucks. This allows manufacturers to make critical adjustments, and improve repeatability and workpiece quality. The wireless version of the chuck force gauge is able to measure RPM along with force.

For more advanced features, such as graphing and testing multiple machines as part of a preventive maintenance plan, a tablet that universally connects to any ForceCheck sensor is also available. Contact us for more specifications and details on advanced machine force measuring.

Wireless Chuck Force Gauges

The ForceCheck wireless chuck force gauge is designed to quickly and accurately measure holding force and speed on chucks. Verifying chuck holding force allows manufacturers to improve the repeatability of a manufacturing process by checking actual holding force under dynamic (rotating) conditions, as well as perform critical preventative maintenance checks. Contact us for other clamping diameters and extension rings, as well as 4+ jaw chucks.  Details

Details  PDF (495.320)

PDF (495.320)

Wired Chuck Force Gauges

Designed to quickly check the holding force on a chuck or turning-center. The wired chuck force gauge can be customized for any diameter.  Details

Details  PDF (495.205)

PDF (495.205)

Runout Test Bars for Lathes, Chucks, and Turning Centers

VDI Runout Test Bars

Runout testing bar for VDI interface. Used for both testing run-out of the interface as well as center alignment and adjustment on a lathe. Made to DIN 69880 standard.  Details

Details  PDF (465.V00)

PDF (465.V00)

| DIN 69880 | d1 | d3 | d6 | L1 | L3 | Order Number | ||

|---|---|---|---|---|---|---|---|---|

| VDI 20 | 20 | 40 | 50 | 150 | 15 | 465.V20.000.000

|

||

| VDI 25 | 25 | 40 | 58 | 150 | 15 | 465.V25.000.000

|

||

| VDI 30 | 30 | 40 | 68 | 200 | 15 | 465.V30.000.000

|

||

| VDI 40 | 40 | 40 | 83 | 200 | 15 | 465.V40.000.000

|

||

| VDI 50 | 50 | 40 | 98 | 200 | 15 | 465.V50.000.000

|

Runout Test Arbors for Turning Centers

TAC Rockford runout arbors for lathe centers are manufactured using hardened gauge-quality steel, and include a certificate of accuracy.  Details

Details  PDF (490.520)

PDF (490.520)

| Description | Length (mm) | Diameter (mm) | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| Runout Arbor for Centers | 300 | 32 | 490.520.032.300

|

|||||

| Runout Arbor for Centers | 400 | 35 | 490.520.035.400

|

|||||

| Runout Arbor for Centers | 250 | 40 | 490.520.040.250

|

|||||

| Runout Arbor for Centers | 500 | 40 | 490.520.040.500

|

|||||

| Runout Arbor for Centers | 600 | 50 | 490.520.050.600

|

|||||

| Runout Arbor for Centers | 500 | 63 | 490.520.063.500

|

|||||

| Runout Arbor for Centers | 700 | 70 | 490.520.070.700

|

|||||

| Runout Arbor for Centers | 1000 | 80 | 490.520.080.01K

|

|||||

| Runout Arbor for Centers | 750 | 80 | 490.520.080.750

|

|||||

| Runout Arbor for Centers | 1000 | 90 | 490.520.090.01K

|

|||||

| Runout Arbor for Centers | 800 | 90 | 490.520.090.800

|

Runout Test Arbors for Chucks

TAC Rockford manufacturers runout arbors for chucks as a special order item. Please contact us for further information.  Details

Details  PDF (490.510)

PDF (490.510)

Lathe Spindle Face Ring and Taper Plug Gauges

For measuring the dimensions of lathes and chucks

Series 492.026 ring gauges are for lathe spindle face.

Series 492.028 plug gauges are for chuck back side mounting face.

Taper gauges can be custom-manufactured to customer specifications. Hard chrome-plate and tungsten carbide gauges also available.

Cases are not included. Contact us for high quality gauge crib and travel case options.

| Standards | Size | d2 max. | d2 min. | Gauge | Order Number | |||

|---|---|---|---|---|---|---|---|---|

| DIN55026-3, DIN55027-3, A1-3, A2-3, B1-3, B2-3 | 3 | 53.983 | 53.975 | Ring | 492.026.003.000

|

|||

| DIN55026-4, DIN55027-4, A1-4, A2-4, B1-4, B2-4 | 4 | 63.521 | 63.513 | Ring | 492.026.004.000

|

|||

| DIN55026-5, DIN55027-5, A1-5, A2-5, B1-5, B2-5 | 5 | 82.573 | 82.563 | Ring | 492.026.005.000

|

|||

| DIN55026-6, DIN55027-6, A1-6, A2-6, B1-6, B2-6 | 6 | 106.385 | 106.375 | Ring | 492.026.006.000

|

|||

| DIN55026-8, DIN55027-8, A1-8, A2-8, B1-8, B2-8 | 8 | 139.731 | 139.719 | Ring | 492.026.008.000

|

|||

| DIN55026-11, DIN55027-11, A1-11, A2-11, B1-11, B2-11 | 11 | 196.883 | 196.869 | Ring | 492.026.011.000

|

|||

| DIN55028-3, DIN55029-3 | 3 | Plug | 492.028.003.000

|

|||||

| DIN55028-4, DIN55029-4 | 4 | Plug | 492.028.004.000

|

|||||

| DIN55028-5, DIN55029-5 | 5 | Plug | 492.028.005.000

|

|||||

| DIN55028-6, DIN55029-6 | 6 | Plug | 492.028.006.000

|

|||||

| DIN55028-8, DIN55029-8 | 8 | Plug | 492.028.008.000

|

|||||

| DIN55028-11, DIN55029-11 | 11 | Plug | 492.028.011.000

|

Steep Taper Spindle Plug Gauges

TAC Rockford gauges are used for inspection of steep taper spindle tapers per CAT, ISO, JIS, DIN, etc. Available for Steep Taper 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60,...

Drive Key Spindle Gauges

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face. Two measuring gauges in storage case:...

Electronic Tool Taper Gauges

The four transducers mounted in the measuring ring are used for differential measurement of gauge dimensions d2 and d3. Deviations from the calibrated taper plug gauge are...

Dial Indicator Tool Taper Gauges

Both measuring gauges are set to zero with the calibrated taper plug gauge. When an HSK tool holder is inserted in the ring gauges, deviations in diameters d2 or d3 are shown...

Tool Holder Taper Sleeve Gauges

Available for Steep Taper CAT/ANSI/DIN/BT/ISO 10, 15, 20, 25, 30, 35 40, 45, 50, 55, 60, 65

Dial Indicator Spindle Taper Gauges

To ensure sustained accuracy at HSK interfaces, we recommend comparison measuring of the geometry of HSK tool shanks and spindles at regular intervals. These checks should...

Morse Spindle Taper Plug Gauges

TAC Rockford Morse spindle taper gauges are for inspection of Morse spindle tapers. Gauges made from a hardened gauge steel, and include a padded carrying case and certificate....

Pneumatic Spindle Taper Gauges

Non-contact measuring with nozzles results in high accuracy and consistency of measuring results. The measuring range can be increased with the built-in dial indicator. This...

Steep Taper Spindle Gauge Manual

Download PDF for instruction manual.

VDI 40 Runout Test Bar, per DIN 69880

Per DIN 69880 standard

Runout testing bar for VDI interface. Used for both testing run-out of the interface as well as center alignment and adjustment on a lathe. Made to DIN 69880 standard.

| Product | Gauge |

| Part Type | Runout Arbor for Centers |

| Taper / Standard | VDI |

| Taper Size | 40 |

| d1 | 40 |

| d3 | 40 |

| d6 | 83 |

| L1 | 200 |

| L3 | 15 |

NotesAll units in millimeters.

Compatible With:VDI 40

| DIN 69880 | d1 | d3 | d6 | L1 | L3 | Order Number | ||

|---|---|---|---|---|---|---|---|---|

| VDI 20 | 20 | 40 | 50 | 150 | 15 | 465.V20.000.000

|

||

| VDI 25 | 25 | 40 | 58 | 150 | 15 | 465.V25.000.000

|

||

| VDI 30 | 30 | 40 | 68 | 200 | 15 | 465.V30.000.000

|

||

| VDI 40 | 40 | 40 | 83 | 200 | 15 | 465.V40.000.000

|

||

| VDI 50 | 50 | 40 | 98 | 200 | 15 | 465.V50.000.000

|

VDI Runout Test Bars

Runout testing bar for VDI interface. Used for both testing run-out of the interface as well as center alignment and adjustment on a lathe. Made to DIN 69880 standard.

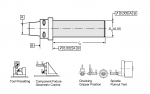

HSK Spindle Runout Test Arbors

Available for HSK-A/C/E 32, 40, 50, 65, 80, 100, 125, 160 and HSK-F 40, 50, 63, 80, 100, 125, 160

Capto Spindle Runout Test Arbors

Available for Polygonal-Shank Taper (Coromant Capto) sizes C3, C4, C5, C6, C8, and C10

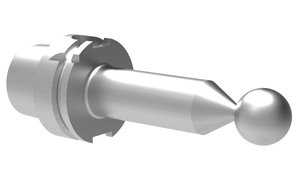

HSK Standard Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter...

Steep Taper Spindle Runout Test Arbors

Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

Steep Taper Standard Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter...

HSK Precision Ball-End Runout Test Arbors

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter...

Spindle Runout Test Arbor Instructions

One of the leading causes of tool breakage, part finish issues, tolerance control, and machine registration issues is excessive spindle runout.

HSK Spindle Runout Test Arbors

Available for HSK-A/C/E 32, 40, 50, 65, 80, 100, 125, 160 and HSK-F 40, 50, 63, 80, 100, 125, 160

• Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

• Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

• A certificate of accuracy is included.

• Contact us for other lengths, tapers, and other special requirements.

| HSK | l1 (mm) | d1 (mm) | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| HSK-A 25 | 140 | 20 | 465.125.000.000

|

|||||

| HSK-A 32 | 180 | 24 | 465.132.000.000

|

|||||

| HSK-A/C/E 40 | 200 | 25 | 465.140.000.000

|

|||||

| HSK-A/C/E 50 and HSK-F 63 | 346 | 32 | 465.150.000.000

|

|||||

| HSK-A/C/E 63 | 346 | 40 | 465.163.000.000

|

|||||

| HSK-A 80 | 346 | 40 | 465.180.000.000

|

|||||

| HSK-A 100 | 300 | 50 | 465.190.000.000

|

|||||

| HSK-A 125 | 349 | 40 | 465.192.000.000

|

|||||

| HSK-A 160 | 400 | 40 | 465.196.000.000

|

|||||

| HSK-F 63 | 346 | 40 | 465.663.000.000

|

|||||

| HSK-F 80 | 346 | 50 | 465.680.000.000

|

Capto Spindle Runout Test Arbors

Polygonal-Shank Taper (PSK) Spindle Runout Testing

Available for Polygonal-Shank Taper (Coromant Capto) sizes C3, C4, C5, C6, C8, and C10

![]() PDF Data Sheet: Capto Spindle Runout Test Arbors (465.C00)

PDF Data Sheet: Capto Spindle Runout Test Arbors (465.C00)

HSK Standard Ball-End Runout Test Arbors

For verification of 5-axis HSK taper spindle machining centers

Ball end spindle runout test arbors are designed checking positioning accuracy of 5-axis machines, but can also be used in place of a standard runout test bars when a shorter length is required or for a touchoff point from the spindle face (ball end is ideal for this purpose).

Ball runout to taper ≤0.010 mm (0.0004"), with a ≤0.002 (0.00008") runout shaft below for checking axial runout.

HSK taper has 4 full-depth drive key slots, allowing the gauge to be rotated by 90 deg. on HSK-A and HSK-C spindles.

Gauge length is measured from the tool holder gauge line to the end of the ball. Other gauge lengths and ball diameters are available -- contact us for more information.

Arbors do not include a carrying case. Visit our carrying case options page for gauge crib upright storage, travel, and customized carrying case solutions.

A certificate of accuracy is included.

| Taper | Gauge Length | Ball Diameter | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E32 + B/D/F40 | Contact us | Contact us | 466.132.000.000

|

|||||

| HSK-A/C/E40 + B/D/F50 | Contact us | Contact us | 466.140.000.000

|

|||||

| HSK-A/C/E50 + B/D/F63 | Contact us | Contact us | 466.150.000.000

|

|||||

| HSK-A/C/E63 + HSK-B/D/F80 | 150 | 30 | 466.163.000.000

|

|||||

| HSK-A/C/E80 + B/D/F100 | 150 | 30 | 466.180.000.000

|

|||||

| HSK-A/C/E100 | 150 | 30 | 466.190.000.000

|

|||||

| HSK-A/C125 | Contact us | Contact us | 466.192.000.000

|

|||||

| HSK-F80 (Makino Flange-Pin Spindles) | 100 | 30 | 466.680.000.000

|

Overview: Spindle Runout Arbor Carrying Cases

Whether your gauges need to be transported on a frequent basis, or need to be stored in one area for a period of time, we can offer a reliable solution.  Details

Details  PDF (465.006)

PDF (465.006)

Spindle Runout Test Arbor Instructions

One of the leading causes of tool breakage, part finish issues, tolerance control, and machine registration issues is excessive spindle runout.  Details

Details  PDF (465.005)

PDF (465.005)

Steep Taper Spindle Runout Test Arbors

Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

• Maximum runout error 0.003mm / 3 micron / 0.0001 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

• Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

• A certificate of accuracy is included.

• Contact us for other lengths, tapers, and other special requirements.

| Item / Taper | L (mm) | D (mm) | Retention Knob Thread | Order Number | ||||

|---|---|---|---|---|---|---|---|---|

| Steep Taper (BT) 30 | 300 | 40 | M12 | 465.730.000.000

|

||||

| Steep Taper (BT) 40 | 300 | 40 | M16 | 465.740.000.000

|

||||

| Steep Taper (BT) 50 | 300 | 40 | 465.750.000.000

|

|||||

| Steep Taper (DIN) 30 | 300 | 32 | M12 | 465.830.000.000

|

||||

| Steep Taper (DIN) 40 | 300 | 40 | M16 | 465.840.000.000

|

||||

| Steep Taper (DIN) 45 | 300 | 50 | M20 | 465.845.000.000

|

||||

| Steep Taper (DIN) 50 | 300 | 50 | M24 | 465.850.000.000

|

||||

| Steep Taper (DIN) 60 | 400 | 50 | M30 | 465.860.000.000

|

||||

| Steep Taper (CAT/ANSI) 40 | 300 | 40 | 5/8"-11 | 465.940.000.000

|

||||

| Steep Taper (CAT/ANSI) 50 | 300 | 50 | 1"-8 | 465.950.000.000

|

||||

| Steep Taper (CAT/ANSI) 60 | Contact us | Contact us | Contact us | 465.960.000.000

|

||||

| Steep Taper (ISO) 10 | Contact us | Contact us | Contact us | 465.A10.000.000

|

||||

| Steep Taper (ISO) 15 | Contact us | Contact us | Contact us | 465.A15.000.000

|

||||

| Steep Taper (ISO) 20 | Contact us | Contact us | Contact us | 465.A20.000.000

|

||||

| Steep Taper (ISO) 25 | Contact us | Contact us | Contact us | 465.A25.000.000

|

Overview: Spindle Runout Arbor Carrying Cases

Whether your gauges need to be transported on a frequent basis, or need to be stored in one area for a period of time, we can offer a reliable solution.

KM Spindle Runout Test Arbors

Available for KM40, KM50, KM63, and KM100. Contact us for custom arbors.

• Maximum runout error 0.005mm / 5 micron / 0.0002 inch. Contact us for availability on ultra-precision 0.001mm runout arbors.

• Carrying cases are not included. Visit www.tac.us/runoutcases for available case styles (Data Sheet 465.006).

• A certificate of accuracy is included.

• Contact us for other lengths, tapers, and other special requirements.

| Taper | Length | Diameter | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| KM32 Runout Arbor | Contact us | 465.K32.000.000

|

||||||

| KM40 Runout Arbor | Contact us | 465.K40.000.001

|

||||||

| KM50 Runout Arbor | Contact us | 465.K50.000.001

|

||||||

| KM63 Runout Arbor | 340 | 50 | 465.K63.000.000

|

|||||

| KM63 Runout Arbor | 120 | 63 | 465.K63.000.001

|

|||||

| KM80 Runout Arbor | Contact us | 465.K80.000.000

|

||||||

| KM100 Runout Arbor | 340 | 50 | 465.K90.000.000

|

|||||

| KM100 Runout Arbor | 120 | 100 | 465.K90.000.001

|

Overview: Spindle Runout Arbor Carrying Cases

Whether your gauges need to be transported on a frequent basis, or need to be stored in one area for a period of time, we can offer a reliable solution.  Details

Details  PDF (465.006)

PDF (465.006)

Steep Taper Dual-Contact Runout Test Arbors

Steep taper runout test bars for Big Plus spindles.

Spindle runout test bars for dual-contact Big Plus steep taper sizes 30, 40, 50 and CAT/ANSI 40 and 50. Test bars contact on both the taper and flange face.

Gauges include certificate and storage case.

| Spindle Taper | L | D | Order Number | |||||

|---|---|---|---|---|---|---|---|---|

| Steep Taper (BT) 30 | 235mm | 32mm | 465.F30.000.000

|

|||||

| Steep Taper (BT) 40 | 350mm | 50mm | 465.F40.000.000

|

|||||

| Steep Taper (BT) 50 | 360mm | 50mm | 465.F50.000.000

|

|||||

| Steep Taper (CAT/ANSI) 40 | 13.5" | 2" | 465.G40.000.000

|

|||||

| Steep Taper (CAT/ANSI) 50 | 13.5" | 2" | 465.G50.000.000

|