E-Catalog > ONIKAZE (AKAMATSU) > ONIKAZE Mist collector

Product Information :

- เครื่องจักร, อุปกรณ์เกี่ยวกับเครื่องจักร, เครื่องมือกล

- ONIKAZE (AKAMATSU)

- สินค้า, ผลิตภัณฑ์

Product Detail :

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Feature | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application examples | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| [Various machine tools] ANC-CNC lathe, soaping machine, multi-purpose lathes, machining center, NC mailing cutters, gear hobbing machines, grinding machine, automatic board, a drill press, broaching machine, transfer machine, gun drills etc. [Molding machines] Die-casting machines, injection molding machines(resins), large presses etc. [Additional applications] Molding equipment, quenching machines, induction shrink fit equipment, rolling mills, rolling machines, header units, nut formers, lens chamfering, lens grinding, ceramic processing, glass processing, washer units, coating equipment, air blowers, for food, pharmaceuticals and cosmetic products etc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specifications | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Installation example | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Feature | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application examples | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| [Various machine tools] NC/CNC lathe, multi-purpose lathes, machining center, NC mailing cutters, milling cutters, gear hobbing machines, grinding machine, automatic lathes, drill press, broaching machine, transfer machine, gun drills etc. [Molding machines] Die-casting machines, injection molding machines(resins), large presses etc. [Additional applications] Molding equipment, quenching machines, induction shrink fit equipment, rolling mills, rolling machines, header units, nut formers,lens chamfering, lens grinding, ceramic processing, glass processing, washer units, coating equipment, air blowers, for food, pharmaceuticals and cosmetic products etc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specifications | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Installation example | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| FM-220 The Omnipotent dust collector which attached importance to fire prevention and collection efficiency |

|||||||||||||||||||||||||||||||||

| Feature | |||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

| Application examples | |||||||||||||||||||||||||||||||||

| Welding Hume, laser beam machine, blowout machine, grinder, food factory, medicine factory, cookroom oil mist, exhaust gas treatment(service station etc.), forge, casting oil mist, such as a die-cast machine,abundant mist of particulate mixture, etc. |

|||||||||||||||||||||||||||||||||

| Specifications | |||||||||||||||||||||||||||||||||

The highest inhalation temperature is 75 degrees.(Atmosphere is 40 degrees or less. |

|||||||||||||||||||||||||||||||||

| Installation example | |||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

Akamatsu Electric Mfg.Co.,Ltd |

|||||||||||||||||||||||||||||||||

HVS-150-007 NO.044.045.046

HVS-40 3PH 200/220V 50/60HZ 400W

HVS-100 :FU-100 HVS-220 RF-220 HVS-220 DF-220/DF-300 HVS-220 FU-220 HVS-220-

SMM-100 200/220V 50/60HZ

HVS-40 0.4KW 2P 4.0/4.8m3/min 690/980pa 200V/50/60HZ

HVS-100-GB2 200V 50HZ

FU-220.

FU-150.

HVS-150

SMM-100

HVS150 1.5KW 200V/50HZ 60HZ

HVS100 0.75KW 200V/50HZ 60HZ

FU-220

DF-220

FU-150

DF-150

HVS-150 3P/380V

RU-150 DF-150 FU-150

HVS-150-GB2 200V 50HZ

SMM-100 380V 50HZ

HVS-100

HVS-150RV-150

HVS-220

SMM-40 0.4KW 3PH200V/50/60HZ

SMM-100 0.75KW 3PH200V/50/60HZ

SMM-20 AC200\220V 50/60HZ

HVS-150-CE

CRD-400R HVS-40 200V 50HZ

HVS-300 RU-300

HVS-300 RF-300

HVS-300 DF-300

HVS-300 FU-300

HVS-300 SD-300

HVS-220 2.2KW 2P 380V/50HZ

RS-301 130W 380V/50HZ

HVS-100 FU-100

HVS-150 FU-150

HVS-220 FU-220

HVS-300 BS-300

HVC-220 380V/50HZ

HVS-220-CE-000

HVS-220

HVS-100D 0.75KW 200V/50/60HZ

HVS-150

HVS-100-GB3 380V 50HZ

HVS-220:RF-220

HVS-220:BU-220

HVS-220:DF-220/DF-330

FU-220

SD-220

DF-220.

RF-220

SD-150

DF-150

RF-150

FU-100

SD-100

DF-100

RF-100

D-150

BU-150

BF-150

SMG-100 0.75KW 2P 200V/50/60HZ

Φ32 GHH-100-32

SD-150

RU-150

FU-150

DF-150

HVS-150-GB3 1.5KW 3PH200V/50/60HZ

HVS-100 0.75KW 2P 9/11m3/min 1030/1470pa 200V/50/60HZ

HVS-220AV200V 1.5KW

HVS-150 1.5KW AC200V 50/60HZ

HVS-150BS-150

BS-150

DF150

DC-40

OD-40

WF-40

HVS-40(3AC380V 50HZ)

specification

| format | HVS-40 | HVS-100 | HVS-150 | HVS-220 | HVS-300 | HVS-2500 |

|---|---|---|---|---|---|---|

| power supply | HVS-40 200/200/220 / 230V 50/60/60 / 60HZ HVS-100 ~ 2500 200/200 / 220V 50/60 / 60Hz |

|||||

| Processing air volume (m 3 / min) | 4 / 4.8 | 9/11 | 14.2/17 | 22/26 | 23.5 / 28 | 27.5 / 33 |

| Static pressure (Pa) | 690/980 | 1030/1470 | 1520/2150 | 1570/2450 | 1680/2350 | 1720/2450 |

| Collection efficiency | 99.93% removal of particles larger than 0.3 micron | |||||

| Electric motor | 0.4kW 2Pole | 0.75kW 2Pole | 1.5kW 2Pole | 2.2kW 2Pole | 2.2kW 2Pole | 2.2kW 2Pole |

| Paint color | 25-90C Munsell 5Y9 / 1.5 Approximate polyester powder coating |

|||||

| External dimensions (W x D x H) | 340 x 696 x 520 | 470 x 776 x 655 | 520 x 866 x 735 | 600 x 936 x 830 | 600 x 1008 x 980 | 750 x 1232 x 1270 |

| Inhalation caliber | 98 | one two three | 148 | 198 | 198 | 198 |

| Discharge diameter | ―――― | one two three | 148 | 198 | 198 | 198 |

| Noise (dB (A)) | 50/54 | 58/62 | 62/68 | 68/71 | 61/64 | 62/64 |

| Mass (kg) | 35 | 55 55 | 72 | 85 | 108 | 180 |

Maximum suction temperature is 75 ℃ (however, the atmosphere is 40 ℃ or less)

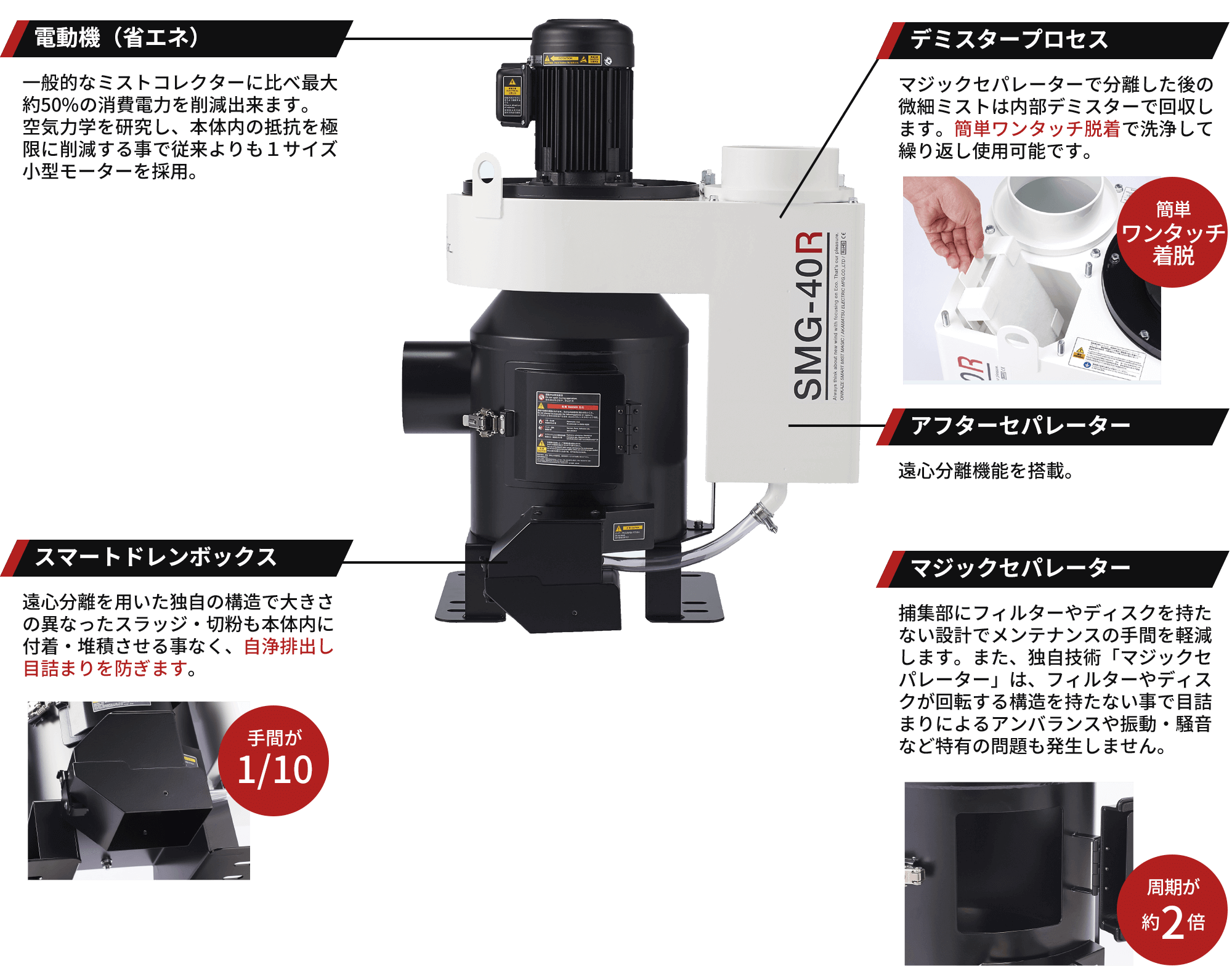

Production accelerates without stopping the site!

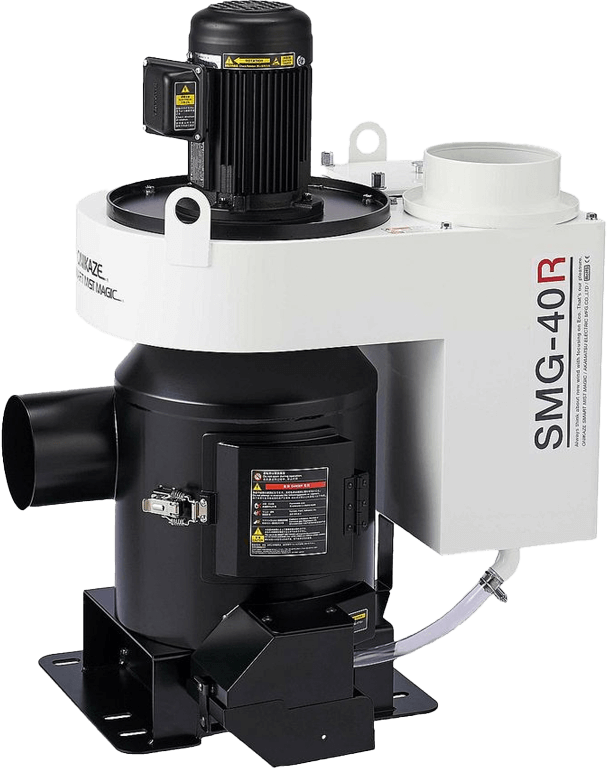

Mist collector who thoroughly pursues energy saving and maintenance reduction

Using centrifugal force, not only mist but also sludge and chips that cause clogging are discharged to the outside of the mist collector body.

It greatly reduces the maintenance effort.

Are you in trouble ?

-

High running cost such as filter replacement

-

Immediately causes clogging

-

I want to reduce my electricity bill

I don't want to do maintenance as much as possible

Reasons for choosing Smart Mist Magic R to improve the on-site environment

Unique technology to solve on-site dissatisfaction

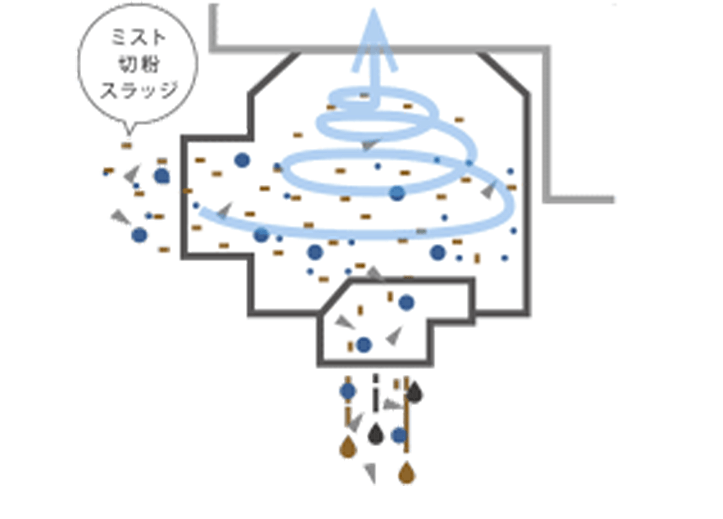

Centrifugal + self-cleaning "magic separator"

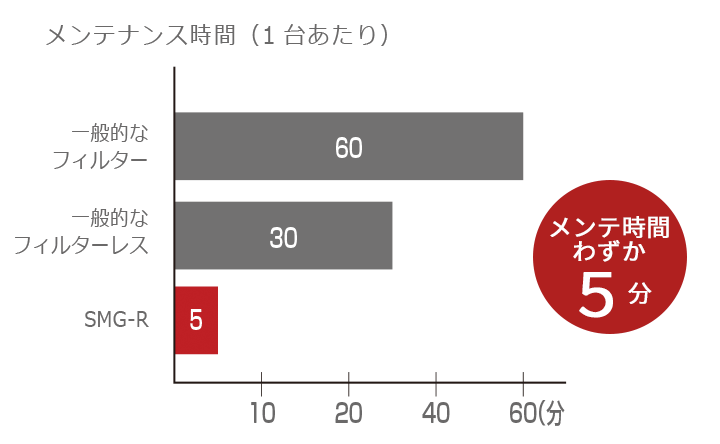

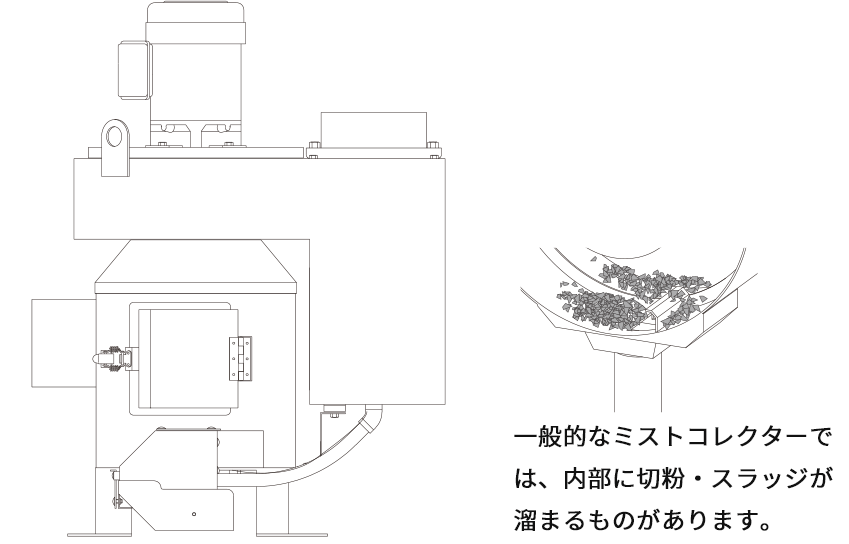

Any method using a filterless structure initially collects mist and exhibits its performance, but with the period of use, severe performance deterioration and frequent maintenance occur due to clogging and accumulation of the internal and collected parts. I will do it.

However, in a factory where multiple mist collectors are installed, it is difficult to stop the processing machine frequently for each maintenance.

Therefore, Onikaze has developed a "magic separator" that can be separated by centrifugation and discharged by self-cleaning.

The world's first new form of filterless. Onikaze's "Magic Separator" mechanism is a completely new centrifugal separation method that does not burden the site, which was devised from many years of experience.

- Discharges without accumulating and staying inside the body

- With a structure that pursues aerodynamics, the sucked mist, sludge, and chips are self-cleaned and do not accumulate inside the main body.

- Holds suction power for a long time

- The structure does not have a filter or disk, which reduces maintenance work and time.

Reason for unique shape

Mist collectors can't be collected, they can't be clogged. Ease of maintenance, low electricity bill, and total balance are important for long-term use.

- "Shape" that does not accumulate

- The mist collector cannot be judged only by the initial performance. Smart Mist Magic R is a special shape that maintains its performance for a long period of time.

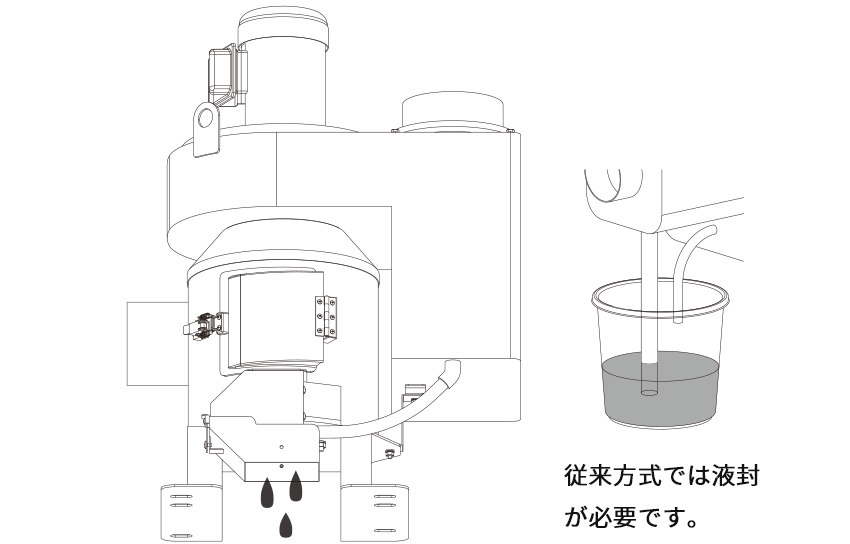

- Troublesome drain processing "unnecessary"

- It can be used immediately after installation to reduce the burden on the operator. Of course, it can also be used by connecting a drain hose.

Internal structure

- Overseas standard (standard equipment)

- Equipped with a motor that complies with each country's standard as standard (SMG-100R / 150R) It has excellent cost performance because it can be shipped to each country without changing the motor.

World support

- Japan: Top Runner IE3 (Premium Efficiency)

- USA / Canada: NEMA Premium, UL / CSA

- Europe: CE, IE3

▼ China: Click here for GB2

Cost reduction without using a filter!

Power consumption 50% OFF

Thorough pursuit of maintenance-free with our unique magic separator!

Internal structure

feature

Filterless (self-cleaning discharge)

- Achieves filterless by adopting a magic separator. Reduced filter replacement costs.

- * Magic separator (PAT acquisition)

The sucked mist swirls inside the cylindrical magic separator and is discharged to the drain by the force of a strong wind.

The simple cylindrical shape eliminates sludge accumulation and trouble factors. - Not only the caught mist, but also sludge such as chips and polishing powder that cause clogging is discharged from the drain without staying inside the main body.

Cost reduction

By discharging sludge, which is a major cause of clogging, without retaining it, it prevents the suction power from decreasing, and the simple structure greatly reduces maintenance work.

Oil leak measures

A groove is installed around the suction port and discharge port to prevent liquid dripping to prevent the main body and floor from getting dirty.

RoHS compliant

It does not use prohibited substances such as lead and hexavalent chromium, and minimizes the impact on the human body and the environmental load.

Zero waste

- The sucked mist hits the collision plate and then is adsorbed by the demister.

- The demister is made of metal, eliminating replacement parts and achieving zero waste.

Energy saving

- By eliminating the filtration filter (cloth) and reducing the resistance inside the main body, the motor is one size smaller.

- Co2 emissions and power consumption are reduced by up to about 50%. (Compared to our company)

Overseas standard

In response to growing international environmental awareness, SMM-100 / SMM-150 are CE marking compliant specifications.

▼ Click here for details on standard revision

PSE compatible

Compatible with SMM-20 and SMM-40.

specification

| format | SMM-20 | SMM-40 | SMM-100 | SMM-150 |

|---|---|---|---|---|

| power supply | AC200 / 220V 3φ 50 / 60Hz |

|||

| Processing air volume (m 3 / min) | 3.8 / 4.5 | 7.4 / 8.7 | 10/13 | 19/22 |

| Static pressure (Pa) | 650/1000 | 900/1200 | 1140/1600 | 1400/2000 |

| Electric motor | 0.2Kw2Pole | 0.4Kw2Pole | 0.75Kw2Pole | 1.5Kw2Pole |

| Paint color | Body: N-90 (white) Munsell N-9 approximation Stand / motor part: N-10 (black) Munsell N-1 approximation |

|||

| Inhalation caliber | 98 | one two three | 148 | 198 |

| Discharge diameter | 98 | one two three | 148 | 198 |

| Noise (dB (A)) | 64/70 | 69/72 | 69/73 | 74/78 |

| Allowable suction temperature | -10 to 75 ° C However, the atmospheric temperature of the motor section should be 40 ° C or less. |

|||

| External dimensions (W x D x H) | 320 x 731 x 503 | 400 x 839 x 615 | 480 x 936 x 735 | 530 x 1154 x 795 |

| Mass (Kg) | 32 | 48 | 67 67 | 85 |