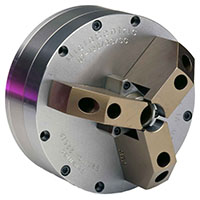

Features

- 4.33” (110mm) chuck diameter

- 3 jaw and 2 jaw models

- QC precision change jaw system and dowel pin located models

- Standard and long stroke models

- 1.063” (27mm) through hole

- Precision fit master jaws to minimize jaw lift

- Hardened chuck body, actuators, and master jaws, for long term accuracy and performance

Repeating Accuracy

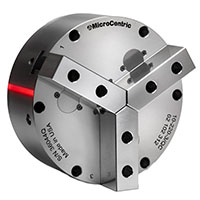

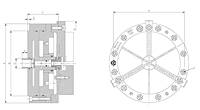

Features

- 6.45” (165mm) chuck diameter

- 3 jaw and 2 jaw models

- QC precision change jaw system

- Standard and long stroke models

- 1.375” (35mm) through hole

- Precision fit master jaws to minimize jaw lift

- Hardened chuck body, actuators, and master jaws, for long term accuracy and performance

Repeating Accuracy

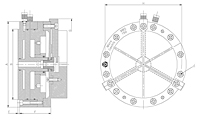

Features

- 8.25” (210mm) chuck diameter

- 3 jaw and 2 jaw models

- QC precision change jaw system

- Standard and long stroke models

- 2.050” (52mm) through hole

- Precision fit master jaws to minimize jaw lift

- Hardened chuck body, actuators, and master jaws, for long term accuracy and performance

Repeating Accuracy

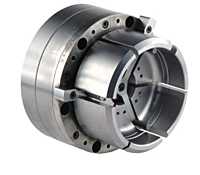

Features

- 10.00” (250mm) chuck diameter

- 3 jaw and 2 jaw models

- QC precision change jaw system

- Standard and long stroke models

- 2.60” (66mm) through hole

- Precision fit master jaws to minimize jaw lift

- Hardened chuck body, actuators, and master jaws, for long term accuracy and performance

Repeating Accuracy

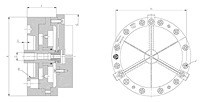

Features

- 12.00” (300mm) chuck diameter

- 3 jaw and 2 jaw models

- QC precision change jaw system

- Standard and long stroke models

- 4.17” (106mm) through hole

- Precision fit master jaws to minimize jaw lift

- Hardened chuck body, actuators, and master jaws, for long term accuracy and performance

Repeating Accuracy

สายด่วน 098-4288648

E-mail : sales@mechatronics.co.th

โทร : คุณภูรินทร์ 0984288648

Quick Change Chucks

-

The CB-NX series is a low profile dead length design with a reduced diameter nose for maximum tool clearance. The collet is coupled directly to the chuck body and remains fixed as the tapered seat moves forward when the chuck is actuated. The collet remains fixed in the Z axis during clamping and therefore does not create a pull back effect on the bar stock or workpiece.

CB-NX Features

- Low Profile Dead Length design

- Reduced diameter nose and short overall length provides increased tool clearance and maximum utilization of the machine's Z axis

- Radial adjusting screws to true-up tapered collet seat within .0002” (0.005mm)

- Lubricated-for-life design requires minimal maintenance

- All components hardened and precision ground for highest accuracy and long life

- Stop plates, stop housings, and ejectors can be mounted inside the chuck body for chucking applications

-

The ND series models are used for collet sizes 120mm and larger. The collet is coupled directly to the chuck body and remains fixed as the tapered seat moves forward when the chuck is actuated. Since the collet remains fixed in the Z axis during clamping it does not create a pull back effect on the bar stock or workpiece.

CB-ND Features

- Dead Length design

- Radial adjusting screws to true-up the chuck assembly within .0002” (0.005mm)

- Lubricated-for-life design requires minimal maintenance

- All components hardened and precision ground for highest accuracy and long life

- Stop plates and stop housings can be mounted inside the chuck body for chucking applications requiring end stops or part ejectors

-

The NS series is a reduced diameter Dead Length design for sub spindles. Similar to ND chucks, the collet is coupled directly to the chuck body and remains fixed as the chuck is actuated. NS chucks also include a provision for mounting stops and ejectors inside the chuck body.

CB-NS Features

- Small OD for maximum tool clearance on sub spindles.

- Dead Length design produces no pull back on the workpiece.

- Lubricated-for-life design requires minimal maintenance.

- All components hardened and precision ground for highest accuracy and long life.

- Stop plates and stop housings can be mounted inside the chuck body for applications requiring end stops or ejectors

- Spindle speeds up to 6,000 rpm

-

In the CB-NB series collet chucks, the collet is coupled directly to the draw tube connector. When the draw tube is actuated, the collet is drawn into the tapered seat of the chuck body, efficiently translating draw tube force into maximum clamping force.

CB-NB Features

- Pull Back design maximizes the efficiency of the clamping system by concentrating all forces in the direction of the spindle for highest accuracy and greatest overall rigidity

- Low profile OD and short overall length provides increased tool clearance and maximum utilization of the machine's Z axis

- Radial adjusting screws to true-up the chuck assembly within .0002” (0.005mm)

- Lubricated for life design requires minimal maintenance

- All components hardened and precision ground for highest accuracy and long life

-

The CB-NDR is a patented Dead Length design for use with servo stop bar loaders. Unlike conventional dead length collet chucks, the NDR is actuated as the draw tube is drawn toward the machine spindle to prevent the bar from being pushed off the servo stop.

CB-NDR Features

- Pull to Close Dead Length design produces no pull back and will not push the bar off the servo stop

- Radial adjusting screws to true-up the chuck assembly within .0002” (0.005mm)

- Lubricated-for-life design requires minimal maintenance

- All components hardened and precision ground for highest accuracy and long life

-

NK series chucks are a pull back design with the added flexibility of being able to mount end stops inside the chuck body for easy conversion from bar to chucking applications. The collet is coupled directly to the draw tube connector. As the draw tube is actuated the collet is drawn into the tapered seat efficiently translating draw tube force into maximum clamping force.

CB-NK Features

- Pull Back design maximizes the efficiency of the clamping system by concentrating all forces in the direction of the spindle for highest accuracy and greatest overall rigidity

- Low profile OD and short overall length provides increased tool clearance and maximum utilization of the machine's Z axis

- Radial adjusting screws to true-up the chuck assembly within .0002” (0.005mm)

- Lubricated-for-life design requires minimal maintenance

- All components hardened and precision ground for highest accuracy and long life

- Removable stop plates and stop housings can be mounted inside the chuck body for chucking applications requiring end stops or part ejectors

-

The NRB series is a hydraulically actuated self-contained Pull Back design for non-rotating applications. The collet is coupled to the built-in piston and is drawn into the tapered seat when the chuck is actuated. Part stops can be mounted inside the chuck body.

CB-NRB Features

- Self-contained design with built-in cylinder can be hydraulic or pneumatically operated

- Pull Back design maximizes the efficiency of the clamping system by concentrating the chucking force in the direction of the machine table, in addition to drawing the workpiece against the part stop

- Lubricated-for-life design requires minimal maintenance

- All components hardened and precision ground for highest accuracy and long life.

Non-rotating dead length designs are quoted on request.

-

The CB-AG series collet chuck is a pull back design with a floating collet seat for machining shafts between centers. Centers or other part locators are mounted in the ID of the chuck. The floating collet seat can also be locked out to clamp parts on-center. Compact OD and short length compared to other compensating chuck designs provides greater rigidity.

CB-AG Features

- 1.5mm (.060”) total compensation

- Mounting in ID of chuck body for mounting locating center

- Radial adjusting screws to true-up locating center within .0002” (0.005mm)

- Lubricated-for-life design requires minimal maintenance

- Compact design for greater rigidity

- Collet seat can be locked out for clamping parts on-center

- All components hardened and precision ground for highest accuracy and long life

-

Shafts can be machined complete between centers with MicroCentric's retractable collet chuck. A face driver mounted in the ID of the chuck drives the shaft as it is supported by the tailstock to turn the end of the shaft. When the chuck is actuated the collet moves forward to clamp the turned diameter enabling the OD of the shaft to be machined completed while the end of the shaft is securely clamped.

WSF Features

- Mounting for face driver in ID of chuck assembly

- Radial adjusting screws to true-up chuck assembly within .0002” (0.005mm)

- All components hardened and precision ground for highest accuracy and long life

MBS Diaphragm Chuck Models

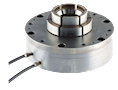

-

Design

Self-contained design with built-in air cylinder. Air is supplied to the chuck by a multi passage air tube assembly with a rotary coupling. Coolant through the spindle capability is standard.

Application

OD and ID chucking for cylindrical grinding, turning, and hard turning. Ideal for workpieces requiring high concentricity, and/or close round ness. Ideal for fragile parts which are easily distorted, and applications requiring high spindle speeds.

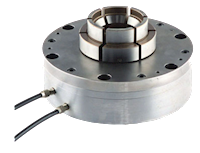

-

Design

Draw tube operated design. Can be actuated with either a hydraulic or pneumatic cylinder mounted at the rear of the machine spindle.

Application

OD and ID chucking for cylindrical grinding, turning, and hard turning. Ideal for workpieces requiring high concentricity, and applications requiring high chucking force and/or high spindle speeds.

-

Design

Self-contained design with built-in air cylinder. Air ports are located on the side of the chuck body for stationary use.

Application

OD and ID chucking for milling, drilling, inspection, or any other non- rotating application requiring high concentricity and/or close workpiece roundness. The inherent spring characteristic of the diaphragm allows workpieces to be clamped without continuous air supply for pallet and tombstone applications.

MBS/N Stationary Diaphragm Chucks

Design

Self-contained design with built-in air cylinder. Air ports are located on the side of the chuck body for stationary use.

Application

OD and ID chucking for milling, drilling, inspection, or any other non- rotating application requiring high concentricity and/or close workpiece roundness. The inherent spring characteristic of the diaphragm allows workpieces to be clamped without continuous air supply for pallet and tombstone applications.

MBS/Z Draw Bar Operated Diaphragm Chucks

Design

Draw tube operated design. Can be actuated with either a hydraulic or pneumatic cylinder mounted at the rear of the machine spindle.

Application

OD and ID chucking for cylindrical grinding, turning, and hard turning. Ideal for workpieces requiring high concentricity, and applications requiring high chucking force and/or high spindle speeds.

MBS/L Air Operated Diaphragm Chucks

Design

Self-contained design with built-in air cylinder. Air is supplied to the chuck by a multi passage air tube assembly with a rotary coupling. Coolant through the spindle capability is standard.

Application

OD and ID chucking for cylindrical grinding, turning, and hard turning. Ideal for workpieces requiring high concentricity, and/or close round ness. Ideal for fragile parts which are easily distorted, and applications requiring high spindle speeds.